3 expanded installation guide, Manifold absolute pressure (map) sensor – Haltech IG5 User Manual

Page 13

9

1.3 Expanded Installation Guide

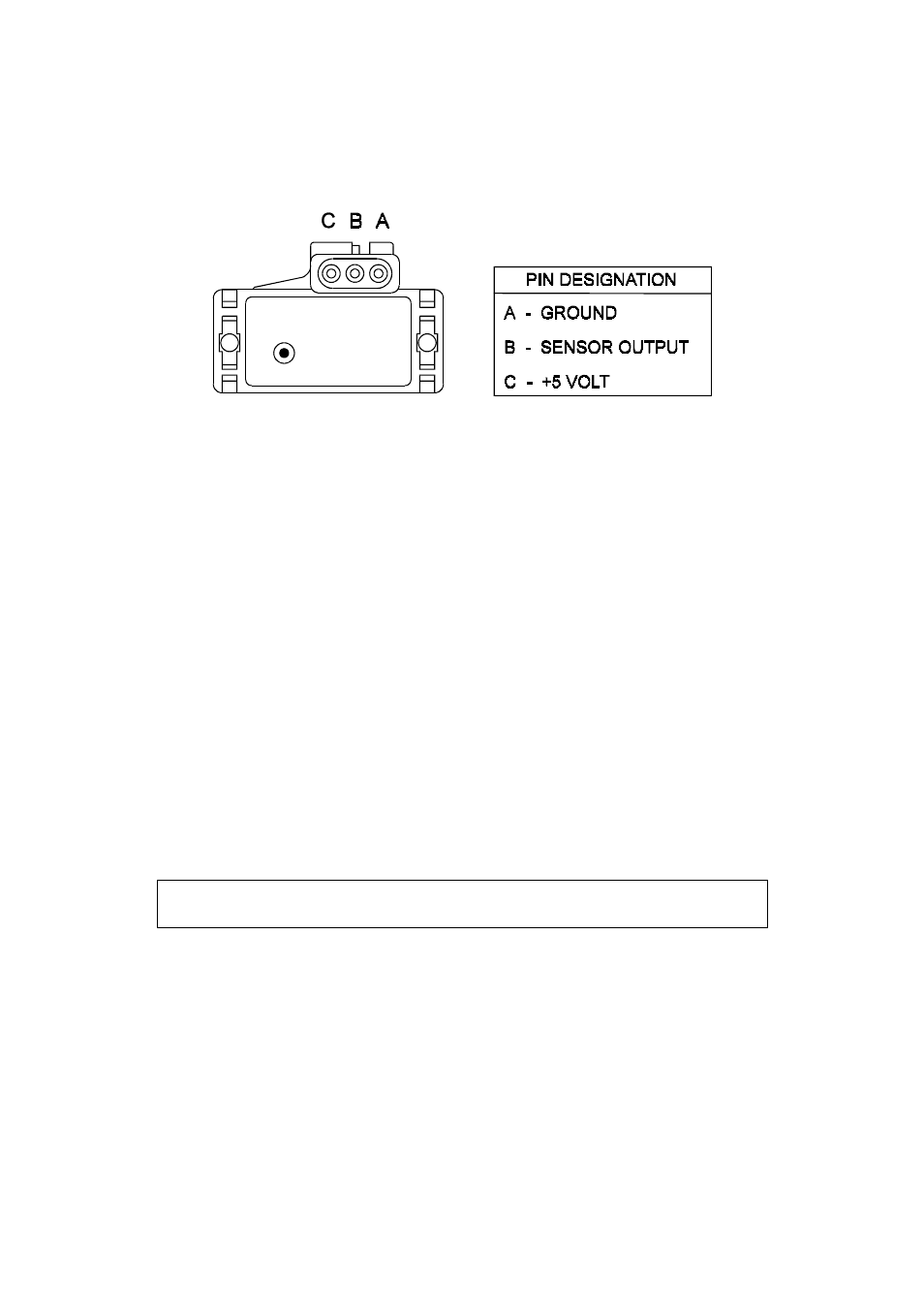

1.3.1. Manifold Absolute Pressure (MAP) Sensor

The MAP sensor is used to convert the manifold pressure into an electrical signal for the IG5

ECU to use. The sensor works in absolute pressures, thus its calibration is not affected by

changes in barometric pressure.

There are three types of MAP sensors that can be used with the IG5 system. The sensor

required depends on the specific engine configuration.

1 Bar Sensor (Part No. 039 4070)

( -100kPa to 0 kPa)

Normally Aspirated Engines

2 Bar Sensor (Part No. 886 3189)

(-100kPa to 100kPa)

Turbo or Supercharged

Engines

up

to

100kPa

boost

(15

psi

,

1

atmosphere)

3 Bar Sensor (Part No. 749 3169)

(-100kPa to 200kPa)

Turbo or Supercharged

Engines

up

to

200kPa

boost

(30

Psi,

2

atmospheres)

Note: Make sure you have the correct MAP sensor for your engine. The first

three digits of the part number is stamped on the sensor housing.

Mounting

The MAP sensor is usually mounted high on the engine bay firewall or inner guard using two

screws with the hose nipple facing outwards. Connect the sensor to the inlet manifold via a

short length of vacuum hose and fasten with either hose clamps or nylon cable ties. Connect

the sensor to the main wiring harness using the appropriate plug. (For 1 Bar sensors the plug

is green, for 2 and 3 Bar sensors the plug is orange). Avoid mounting the sensor below the

level of the fuel system, because fuel may collect in the vacuum hose and run down into the

sensor. The sensor assembly is weather-proof but it is good practice to mount the sensor in a

protected position away from moisture and heat.