A warning, Always use a new cotter pin, Brake shoe inspection – Yamaha pw80 User Manual

Page 45: Brake drum inspection, Tire, Inspection, Caution, Always use a cloth to avoid cutting your hand, Reassembly, Warning always use a new cotter pin

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

3.

Tighten the axle nut and tension bar

nut.

Axle nut torque:

60 Nm (6.0 m*kg, 43 ft»lb)

Tension bar nut:

16 Nm (1.6 m*kg, 11 ft*lb)

4.

Insert the new cotter pin into the ten

sion bar bolt.

A

WARNING

Always use a new cotter pin.

5. Bend the end of the cotter pin.

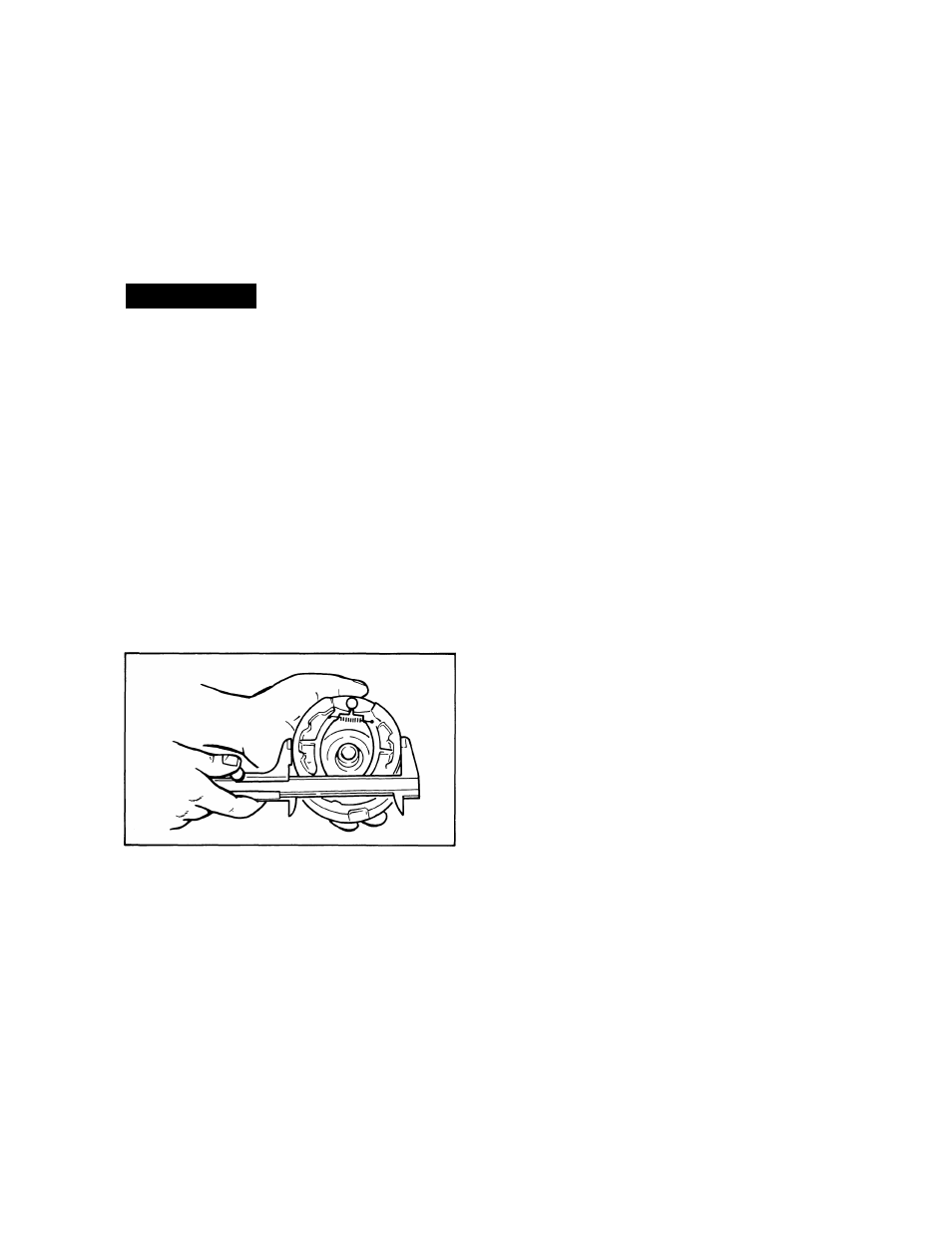

BRAKE SHOE INSPECTION

Measure the outside diameter of the brake shoe

set with slide calipers.

If they measure less than replacement limit,

replace them. Smooth out any rough spots on

shoe surface with sandpaper.

Brake shoe diameter

Replacement limit

Front

95 mm

(3.74 in)

92 mm

(3.62 in)

Rear

110 mm

(4.33 in)

107 mm

(4.21 in)

BRAKE DRUM INSPECTION

Check the inner surface of the brake drum and

remove any scratches with emery cloth.

Remove any oil with a cloth dipped in solvent.

If damage is more extensive, have a Yamaha

dealer or other qualified mechanic replace the

wheel hub.

TIRE

Removal and repair

1. Remove the wheel from the machine.

2. Remove the lock nut from valve stem and

release as much air as possible from the

tire.

3. Push both tire beads away from the edges

of the rim.

4.

Starting opposite the valve stem on one

side, use two round-ended tire irons to

work the bead off the rim.

NOTE: ____ _____________________

Use a tire removal lubricant and be careful not

to pinch the tube vyith the tire irons.

5. Remove the valve stem from its hole and

remove the tube.

6.

If the tire is to be changed, remove the

second bead from the rim using the tire

irons and tire lubricant.

Inspection

1. Use a cloth to check for nails or other

sharp objects in the tire.

CAUTION: _____________________

Always use a cloth to avoid cutting your

hand.

2.

Check for faults in the side wall. If there

is any fault, the tire should be replaced

as a damaged tire may burst at high

speeds, which is extremely dangerous.

3.

Inflate the tube with air and check the

valve stem and the tube for damage and

leakage, replace as required. Some leaks

can be patched in an emergency, but it

is best to replace tube.

Reassembly

1. Install one tire bead on the rim using tire

irons and lubricant and then install the

tube.

2. Inflate tube with air to about one-third the

specified pressure. Hit the outer cir

cumference of the tire with a soft ham

mer to make certain the tube is hot caught

between tire and rim. Release air from

tube.

Inspect rim band and replace if damaged.

Install second tire bead starting opposite

the valve stem using the irons and tire

mounting lubricant.

Inflate tire to approximately 294 kPa (3

kgf/cm^, 42 psi) and then reduce pres

sure to specified setting.

3.

4.

5.

-33-