Belt Drives EVO-10STF User Manual

Page 3

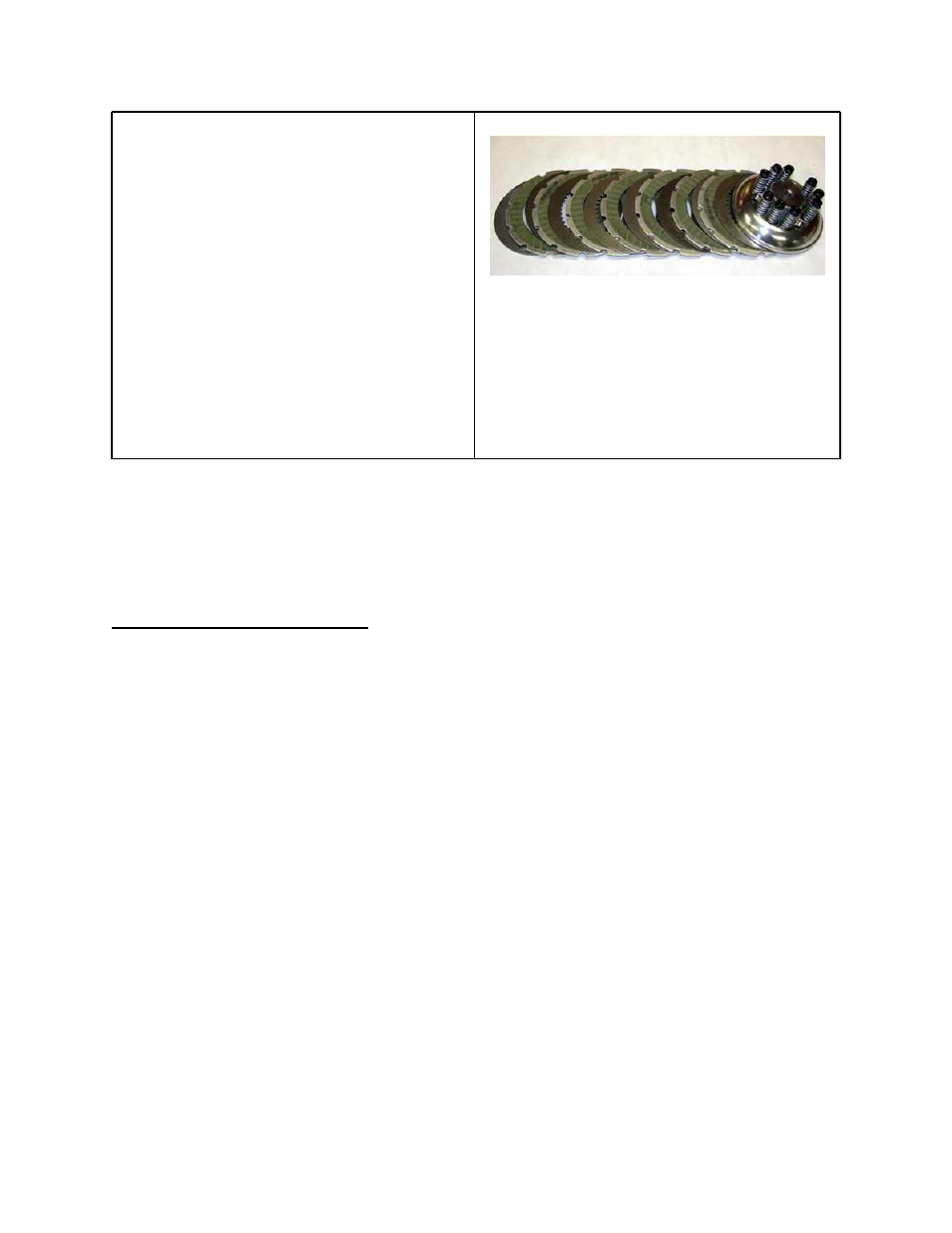

12. Install Quiet Clutch, 1-.120" (EDP-200) spline steel

first, then alternate fiber and steel ending with a

steel.Install pressure plate, springs and shoulder bolts.

install it one turn, go on to the next bolt with same

procedure until all 6 bolts are in place, then tighten

them all the way down until they bottom out. There is

no adjustment to the spring pressure, this is all

pre-determined with the length of the shoulder bolt

and exact dimensions of our pressure plate. (Fig. 5)

Fig. 5

Our pressure plate, EPP-100, is supplied with 9 springs, ECS-100

and 9 bolts, ESB-100. It is not necessary to use more than 8

springs for a stock application. For larger motors it may be

necessary to use 8 or 9 springs.

EDP-200.120 thick steel then alternate fiber and steel ending

with a steel (clutch pack is 1-.120 steel, 7 fibers (ERCP-100), 7

steels (ERCS-100))

13. Install the 4 hexagon extensions into motor plate, shim if necessary with washers supplied and mount side

guard with the 4 buttonhead allen bolts. Note: one hole is countersunk so that this bolt will not interfere with the

midshifter.

14. Clutch screw adjustment should be 3/4 to 1 turn loose from lightly seated. (Note when clutch is hot the

adjustment screw should not be seated). Tighten jam nut when adjustment is complete.

For 3" kick start kits using BDL clutch:

1. Follow steps 1, 2, 3, 5, 10, 11, 13, and 15 above.

3

To install shoulder bolts apply red

Loctite® to a bolt and