Chassis tuning, Rebinding the transmitter to the receiver – Losi LOSB0236BD User Manual

Page 5

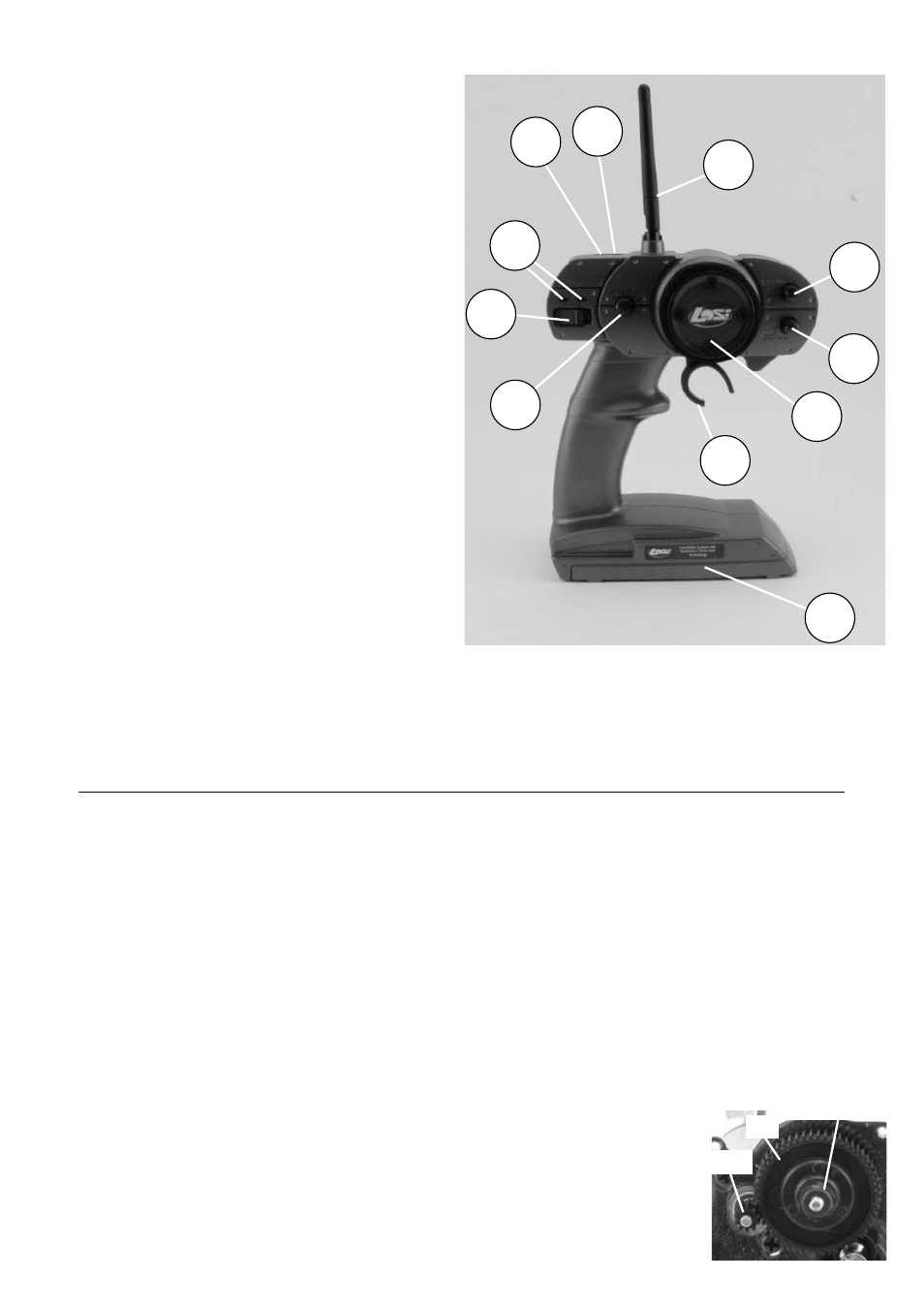

The Transmitter (RTR Version Only)

1. Steering Wheel: Controls direction (left/

right) of the model.

2. Throttle Trigger: Controls speed and

direction (forward/reverse) of the model.

3. Antenna: Transmits signal to the model.

4. On/Off Switch: Turns the power on for the

transmitter operation.

5. Indicator Lights: Green (right) light

indicates adequate battery power. Red

(left) light indicates signal strength.

6. Steering Trim (ST. TRIM): Adjusts the

“hands off” direction of the model.

7. Throttle Trim (TH. TRIM): Adjusts the

motor speed to stop at neutral.

8. Steering Rate: Adjusts amount front

wheels move when the steering wheel is

turned left or right.

9. Steering Reverse Switch (ST. REV):

Reverses the function of the steering

when the wheel is turned left or right.

10. Throttle Reverse Switch (TH. REV):

Reverses the function of the speed control

when pulled back or pushed forward.

11. Bottom Cover: Covers and holds the

batteries powering the transmitter.

1

7

6

3

9

10

5

4

8

11

2

Rebinding the Transmitter to the Receiver

If your Micro Rock Crawler becomes unbound, please refer to page 2 “Bind-N-Drive Getting

Started” section of this manual.

Chassis Tuning

The following are simple adjustments and easily maintained settings to assure proper operation

and performance. It is advised when making any adjustment that you do so in small increments

and always check for other parts of the chassis that are affected.

Center Transmission Slipper

The Micro Rock Crawler is equipped with a slipper device that provides protection for the

transmission. The slipper is primarily used to help absorb sudden impacts on the drivetrain

and is set from the factory and sealed by the gear cover. If the slipper loosens (motor sounds

like it moving but the vehicle doesn’t move), remove the center transmission and cover per the

exploded view. Adjustment is made by turning the adjustment nut clockwise (to the right) to

reduce the slip.

Setting the Gear Mesh

The motor screws should be slightly loose. Slide the motor forward

allowing the pinion gear to mesh with the spur gear. Snug (not tighten) the

bottom motor screw and try rotating the spur back and forth. There should

be a slight bit of movement before the motor is forced to turn over. If not,

pull the top of the motor back slightly and recheck. If there is too much slop

between the gears, push the top of the motor forward. When set properly,

the wheels can be spun forward freely with very little noise. Make sure to

tighten both motor screws and replace the gear cover before running.

Pinion

Gear

Spur

Gear

Slipper

Adjustment Nut

5