Losi LOSB0207 User Manual

Page 10

Changing the Pinion Gear/Gear Ratio

Before you change the pinion gear ask yourself why you are doing it. In general, if you change to a larger pinion the top

speed will improve but you will see less acceleration and run time. Changing to a smaller pinion will give you quicker

acceleration and possibly a bit longer run time but a little less top speed. This would be good for short layouts or when

running hotter motors. The pinion on the Mini HIGHroller offers the best balance of both. To change the pinion,

remove the gear cover, loosen the motor screws, and slide the motor back. Use a pair of small needle-nose pliers

between the motor plate and back of the pinion to push the pinion off. Place the new pinion on the end of the motor

shaft and, using the flat of the pliers or a similar flat tool, push it on to the same position as the one removed. See

Setting the Gear Mesh below.

Warning: When running aftermarket motors, check with the motor manufacturer for correct gearing. Never over-gear the

motor as it can cause overheating, damaging it and the speed control.

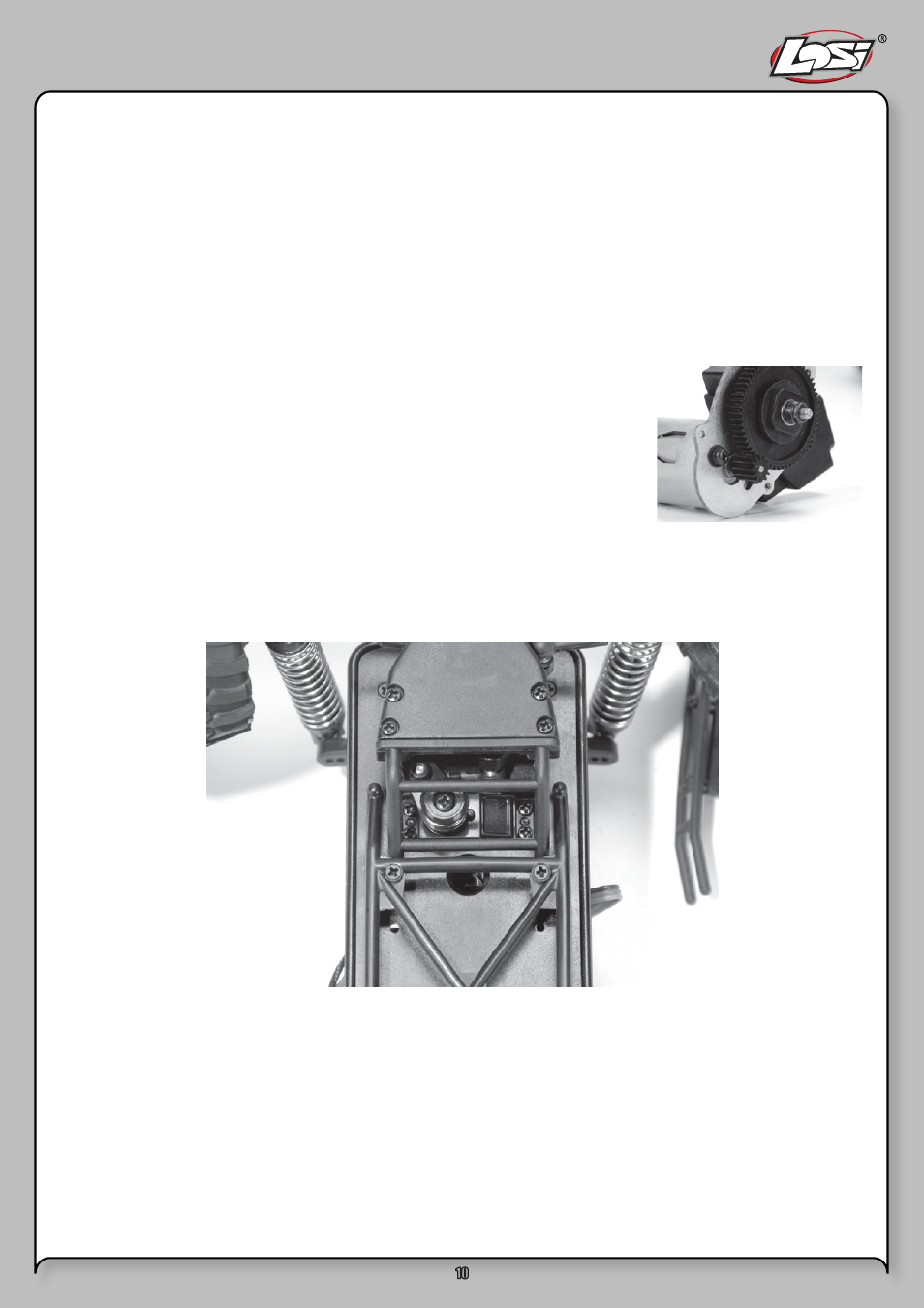

Setting the Gear Mesh

The motor screws should be slightly loose. Slide the motor forward allowing the pinion

gear to mesh with the spur gear. Snug (not tight) the bottom motor screw and try

rocking the spur back and forth. There is a slight bit of movement before the motor is

forced to turn over. If not, pull the top of the motor back slightly and recheck. If there is

too much slop between the gears, push the top of the motor forward. When set prop-

erly the wheels can be spun forward freely with very little noise. Make sure to tighten

both motor screws and replace the gear cover before running.

Steering Servo Installation/Removal

Receiver/Speed Control (ESC) Installation/Removal

Unplug the power lead, motor leads and steering servo. Do not attempt to open the receiver or electronic speed control

(ESC) as only a factory technician has the proper tools and parts to make any repairs necessary. The receiver and ESC

are mounted with double-sided foam tape. Use your thumb and index finger at the bottom of the front corners to pull

them from the mount. If necessary, carefully use a large flat blade screwdriver between the unit and the mount to pry it

loose. Make sure you remove any leftover foam or adhesive before remounting with common servo tape or hobby type

foam tape.

10

Unplug the servo lead from the receiver. Remove the four small screws located on the bottom of the chassis that

secure the servo to the chassis. Use a screwdriver or small pliers to pop the steering link off of the servo, so it can be

removed. Replace in the reverse sequence used to remove it.