Oil lubricated bearings – Goulds Pumps 3409 - IOM User Manual

Page 50

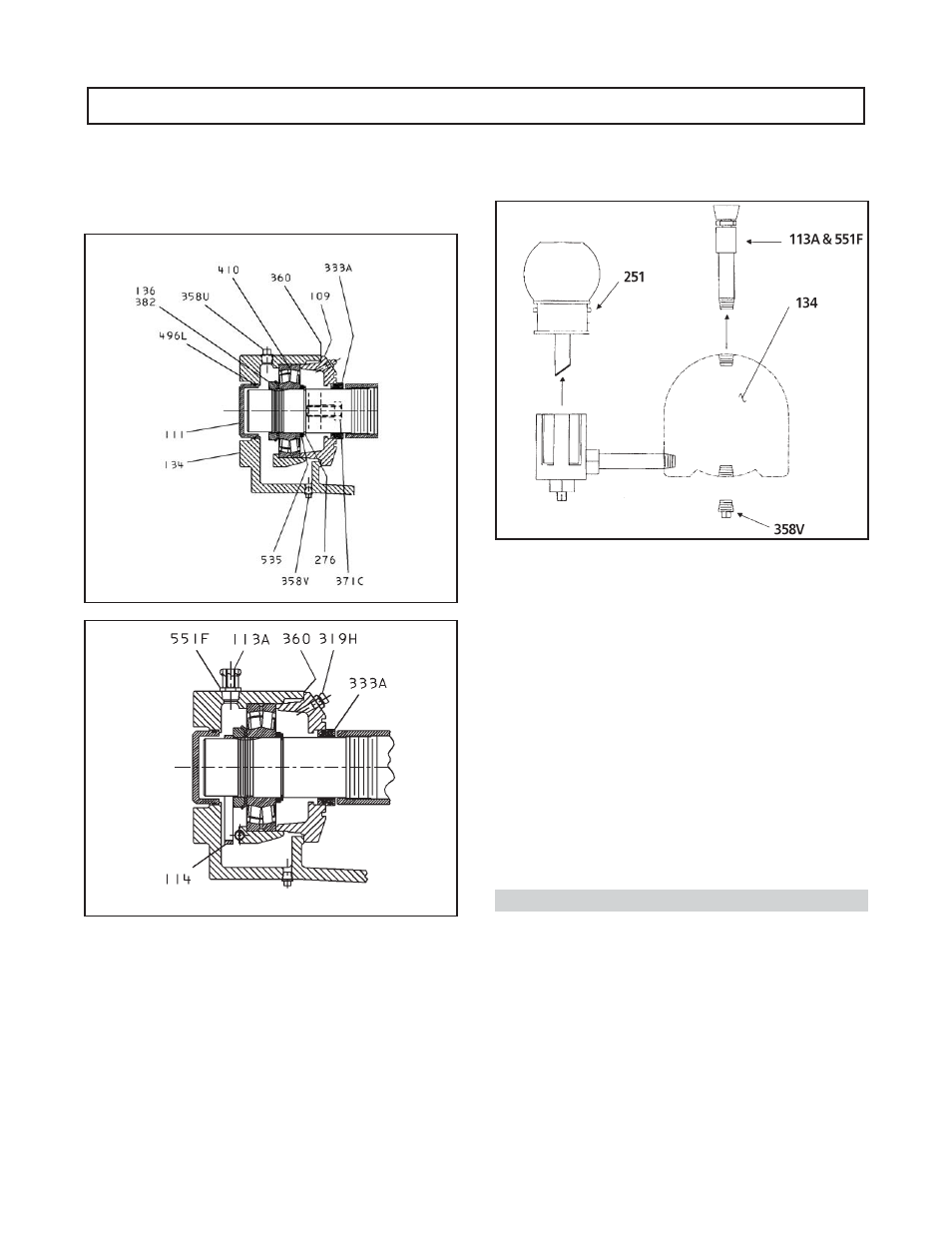

OIL LUBRICATED BEARINGS

Figs. 30 and 31 show a grease lubricated bearing housing and an

oil lubricated bearing housing, respectively. The main

difference between the two is the grease fitting and the oil ring,

respectively.

To install the oil ring (114), place the oil ring in the bearing

housing directly under the pipe plug hole. Run a wire through

the pipe plug hole, around the oil ring and back through the pipe

plug hole once again. Tie the wire to a metal washer (being a

larger diameter than the hole) causing the oil ring to become

tight against the inside top of the bearing housing. Then

assemble the bearing housing over the bearing. Untie the wire

and the oil ring will drop down onto the shaft. Check the

position of the oil ring through the pipe plug hole at the top of

the bearing housing. The oil ring must be resting on the shaft

for correct operation. A screwdriver can be used to correct the

oil ring position, if required.

The following steps describe how to change the oil for oil

lubricating bearings. Fig. 32 shows a typical oiler assembly.

1.

Remove the vent assembly (113A & 551F) from the top

of the bearing housing (134).

2.

Remove the pipe plug (358V) from the bottom of the

bearing housing (134).

3.

Unscrew the reservoir (251) and remove.

4.

Flush the oiler (251) and bearing housing (134) with a

light grade of oil. Flush until all foreign particles have

been removed.

5.

Screw the pipe plug (358V) and vent assembly (113A &

551F) back into place.

6.

Fill the reservoir (251) with a good grade of filtered

mineral oil. Refer to oil lubrication instructions given

previously in this manual for type of oil.

NOTE: You must fill through Trico reservoir.

7.

Place thumb over reservoir spout, invert and place

reservoir (251) on lower casting while removing thumb.

Allow reservoir to empty, filling the bearing housing

(134). Several fillings of the reservoir may be required

before the actual level is reached. When the oil level is

reached, no more oil will run out of the reservoir.

8.

When reservoir stays full, screw reservoir back into lower

casting.

A periodic filling of the reservoir is required. When the oil

becomes dirty, repeat steps 1 through 8.

50

3409 IOM 11/04

Fig. 31

Fig. 30

Fig. 32