Air power pack maintenance, L17 air lubricator, Ms sd – Hawk Industries Spinner Manual 550 HYDRAULIC Serial Numbers 206 to 591 User Manual

Page 32: Air lubricator adjustment, Air lubricator maintenance, 32 maintenance & repair

32

Maintenance & Repair

Air Power Pack Maintenance

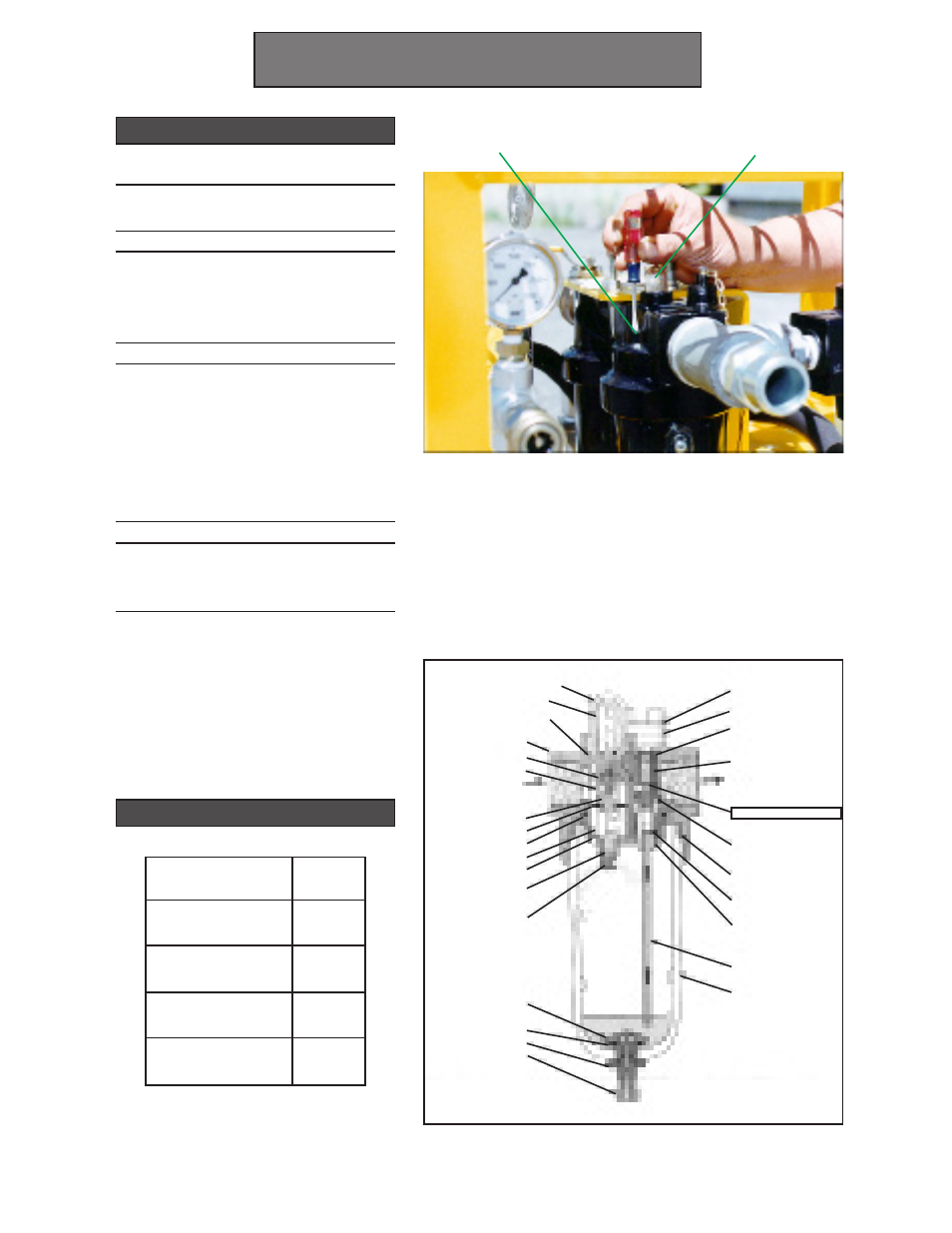

MS

SD

SIGHT DOME GASKET

OUTER SIGHT DOME

BODY

INLET SEAL

PICKUP TUBE

SEAL

FILL CAP

INJECTOR INLET

INJECTOR CONE

RESTRICTOR

BASE SEAL

WHISTLE

BASE

CHECK BALL

CHECK BALL SPRING

DRAIN INSERT

INSERT SEAL

MOUNTING NUT

DRAIN ASS'Y

METER BLOCK TOPSEAL

METER BLOCK

BOWL SEAL

CHECK BALL

CONNECTOR,

PICKUP TUBE

BOWL ASS'Y

SEAL, METER BLOCK

INNER SIGHT DOME

SEAL, METERING SCREW

1. The proper adjustment to the

air lubricator saves oil and maxi-

mizes air motor performance.

2. Using a small flat screw driver,

rotate the lubricator metering

screw (MS) counter-clockwise

to increase oil flow and clock-

wise to decrease oil flow.

3. The proper adjustment is one

(1) drop per minute to minute

and one half when Spinmaster's

main motor is idle, or two (2-3)

drops per connection when

Spinmaster main motor is in

use. To adjust the lubricator, the

power pack must be turned on.

4. Lubricator drops can be seen at

the lubricator sight dome (SD)

located on top of the lubricator as

shown.

Air Lubricator Adjustment

031-L17 Air Lubricator

Air Lubricator Maintenance

DRAIN

002-F17-2

ITEM

P/N