Corothread® 266, Coroturn® xs, Corocut® mb – Sandvik Coromant Threading User Manual

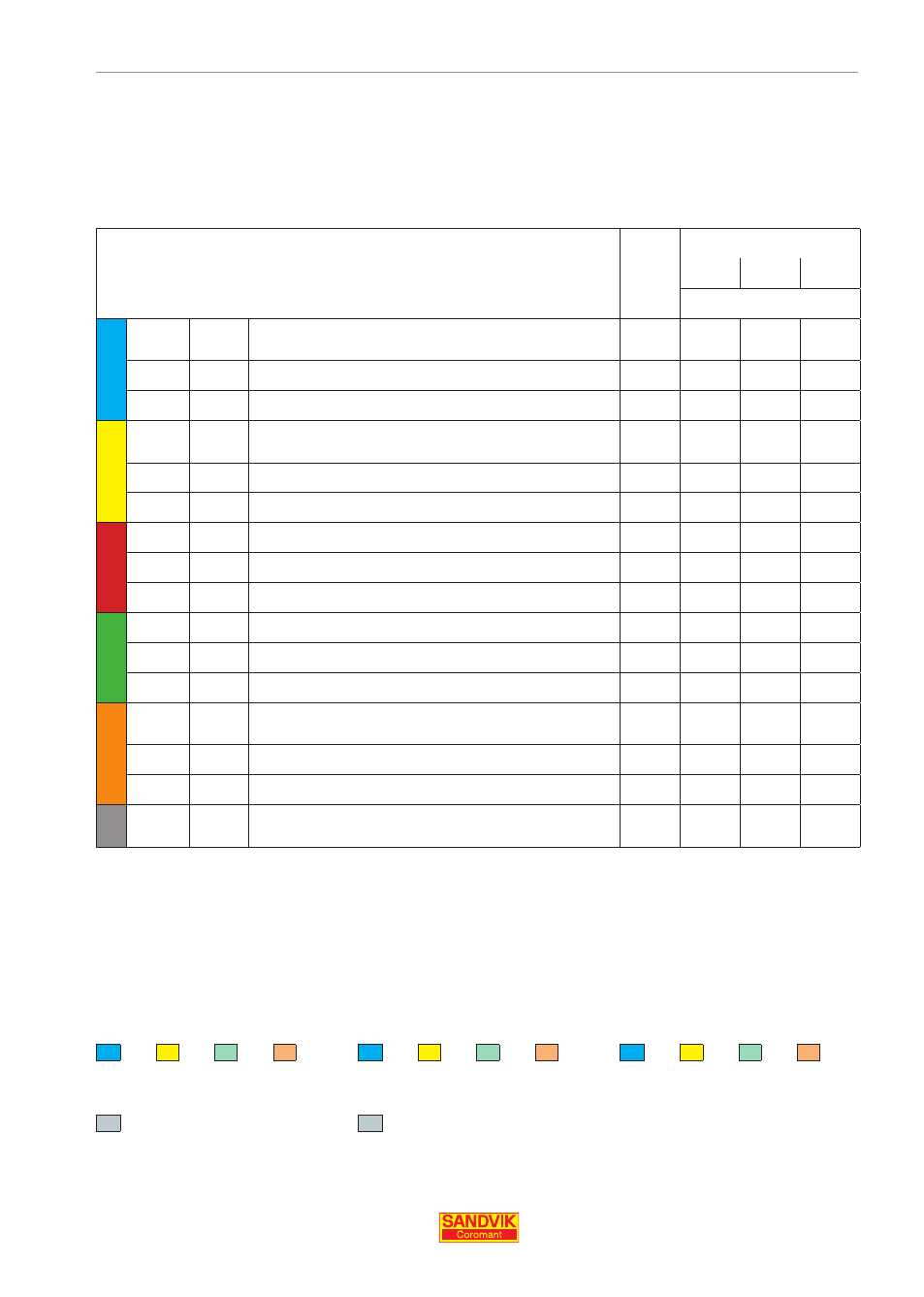

Page 87: Corocut® xs, Thread turning cutting speed recommendations. inch

87

GC1125

GC1135

H13A

P

P1.1.Z.AN 01.1

125

760

670

510

P2.1.Z.AN 02.1

180

510

460

380

P3.0.Z.AN 03.21

325

375

320

230

M

P5.0.Z.AN 05.11

200

520

475

295

M1.0.Z.AQ 05.21

180

460

425

250

M3.1.Z.AQ 05.51

230

360

330

-

K

K1.1.C.NS 07.2

230

410

360

230

K2.2.C.UT 08.2

220

460

425

265

K3.1.C.UT 09.1

160

460

450

355

N

N1.2.Z.UT 30.11

60

1650

1650

1650

N1.3.C.UT 30.21

75

1650

1650

1400

N3.2.C.UT 33.2

90

980

890

490

S

S1.0.U.AN 20.11

200

180

165

145

S2.0.Z.AG 20.22

350

50

50

45

S4.2.Z.AN 23.21

950 Rm

560

520

-

H

H1.3.Z.HA

H1.3.Z.HA

04.1

04.1

46 HRC

60 HRC

200

125

165

105

-

-

CoroTurn® XS

GC1025

P

M

N

S

196-656 196-590 295-1312 65-164

GC7015

H

196-656

CoroCut® MB

GC1025

P

M

N

S

196-656 196-590 295-1312 65-164

GC7015

H

196-656

CoroCut® XS

GC1025/GC1105

P

M

N

S

196-656 196-590 295-1312 65-164

5. Technical reference

CoroThread® 266

Thread turning cutting speed recommendations. inch

For more information about grades and material. see Main catalogue.

Note: Most cutting speeds are recommended for a tool life of 15 minutes.

Cutting speed (v

c

). ft/min

Cutting speed (v

c

). ft/min

Cutting speed (v

c

). ft/min

ISO MC No.

CMC

No.

Material

Hardness

Brinell

Grades

HB

Cutting speed (v

c

) ft/min

Steel

Unalloyed

C = 0.1–0.25%

Low alloyed (alloying elements ≤ 5%)

Non-hardened

High alloyed (alloying elements ≤ 5%)

Hardened tool steel

Stainless steel

Ferritic/matensitic

Non-hardened

Austentic

Non-hardened

Austenitic-ferritic (Duplex)

Non-weldable ≥ 0.05%C

Malleable cast iron

Pearlitic (long chipping)

Grey cast iron

High tensile strength

Nodular cast iron

Ferritic

Aluminium alloys

Wrought or wrought and coldworked. non-aging

Aluminium alloys

Cast. non-aging

Copper and copper alloys

Brass. leaded bronzes. ≤1% Pb

Heat resistant super alloys

Iron base

Annealed or solution treated

Nickel base

Aged or solution treated and aged

Titanium alloys

. near and + alloys. annealed

Extra hard steel

Hardened and tempered