Quality flexibility – Sandvik Coromant Threading User Manual

Page 12

12

2. Applications

Full profi le inserts – fi rst choice for high quality

thread forms

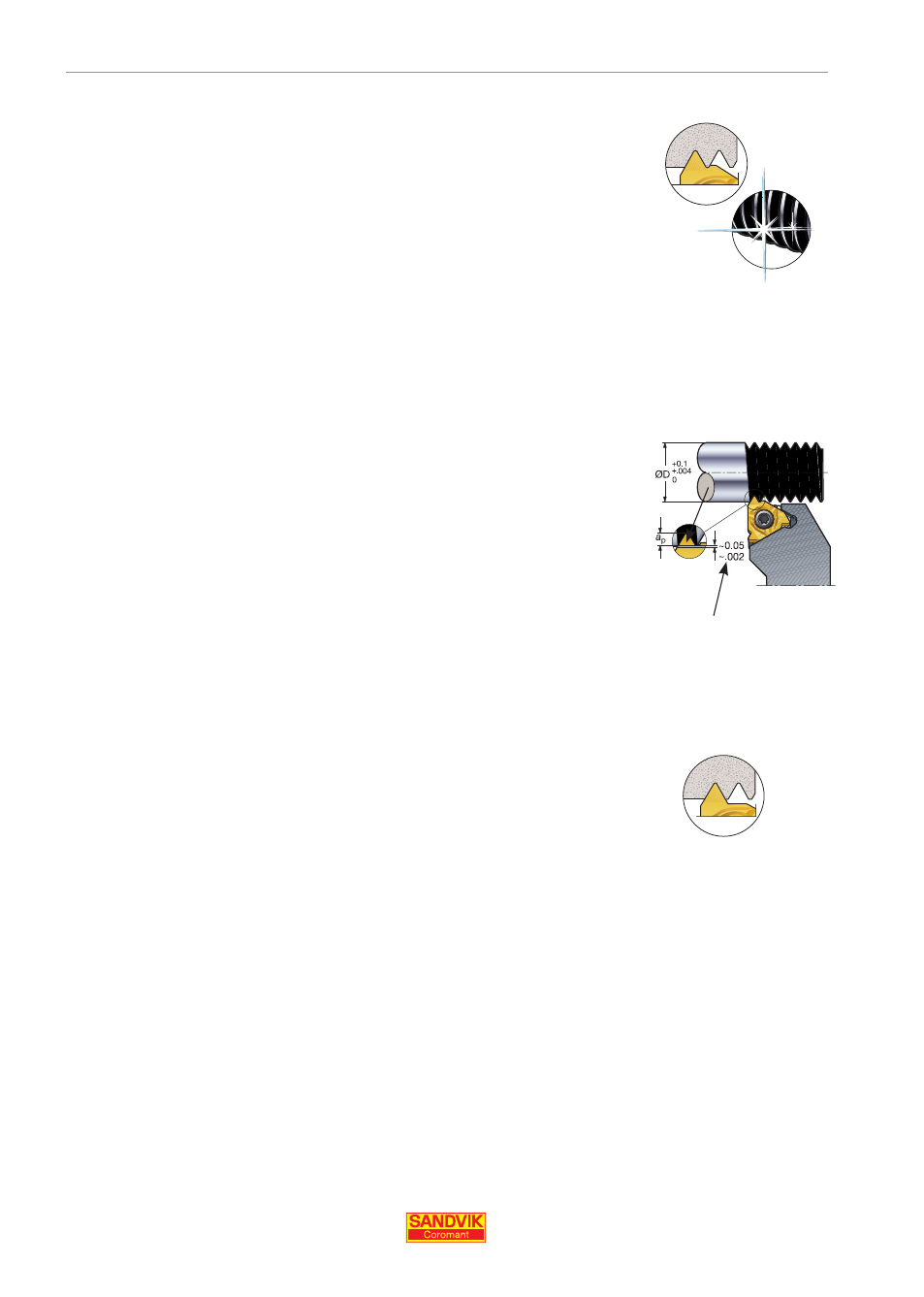

The most common insert type, used to form a complete thread

profi le, including the crest.

• Ensures correct depth, bottom and top profi le for a stron-

ger thread

• Extra stock should be 0.03 – 0.07 mm (0.001 – 0.003”)

• No deburring required after threading operation

• Fewer passes required compared to a V-profi le insert, due

to the larger nose radius

• Separate insert required for each pitch and profi le

• Productive threading performance

Extra stock should be left on the workpiece for topping the fi nish

diameter of the thread.

V-profi le inserts – threading with minimum tool

inventory

These inserts do not top the thread crests. Therefore, the outer

diameter for screws and inner diameter for nuts must be turned to

the right diameter prior to threading.

• Same insert can be used for a range of pitches - provided

that the thread profi le angle (60° or 55°) is the same

• Fewer inserts needed in stock

• The nose radii is designed to offer the smallest pitch,

which reduces tool life

Quality

Flexibility

Extra stock