4 pre-operational checks and trial operation – Harrington Hoists and Cranes HPC 500 End Truck User Manual

Page 18

18

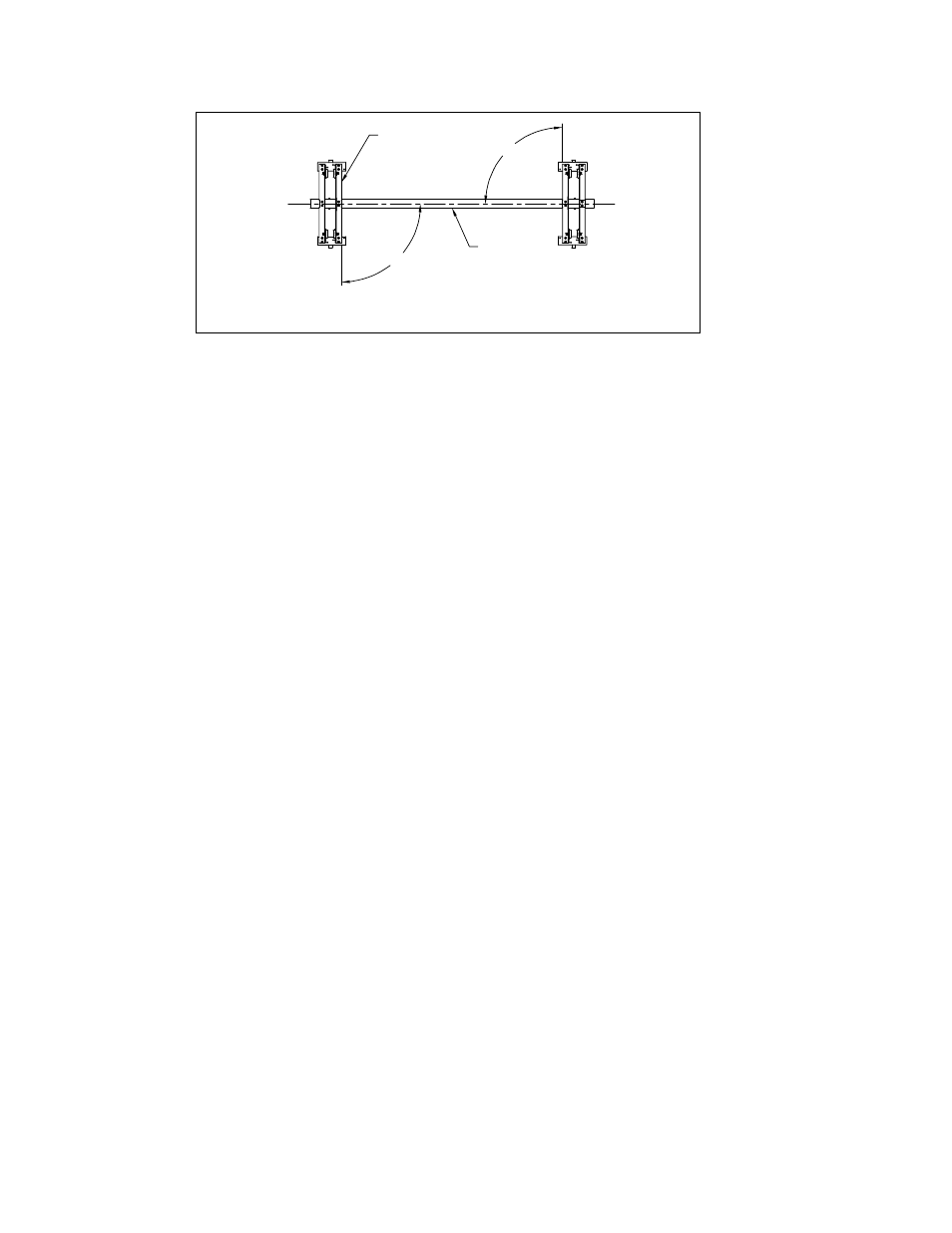

90°

90°

END

TRUCK

BRIDGE

BEAM

Figure 3-11 Crane Squareness

3.4

Pre-operational Checks and Trial Operation

3.4.1

Record the end trucks’ Code and Serial No. from the nameplate (see Figure 10-1) in the space

provided on the cover of this manual.

3.4.2

Ensure that the end trucks are properly installed on the runway beams/rails.

3.4.3

If the end trucks are used as part of an overhead travelling bridge crane, then make sure that the bridge

beam is properly designed, fabricated, and installed.

3.4.4

If a hoist/trolley is used in the system:

Ens

ure the hoist/trolley is properly installed in accordance with the manufacturer’s requirements

and recommendations.

Ensure that the end stops on the bridge beam for the trolley motion are installed correctly and

securely.

3.4.5

Prepare for Trial Operation

Before operating become familiar with operating the equipment (see Section 4

– Operation).

If a hoist/trolley is used in the system, perform pre-operational checks in accordance with the

manufacturer’s requirements and recommendations.

3.4.6

Trial Operation

If the end trucks are used as part of an overhead travelling bridge crane, then move the crane

along the entire length of the runway. Ensure that the crane has proper clearance from

obstructions. Check for proper alignment and clearances of the crane and the end trucks to the

runway (refer to Figure 3-8 and Figure 3-11). Adjust as necessary. Make sure that after any

adjustments the fasteners are properly secured and tightened.

Perform inspections in accordance with Section 5.3, “Frequent Inspections”.

If a hoist/

trolley is used in the system, perform trial operation in accordance with the manufacturer’s

requirements and recommendations.

3.4.7

Load Test

– perform a load test in accordance with ASME B30.11, “Monorails and Underhung Cranes”,

or ASME B30.17, “Overhead and Gantry Cranes (Top Running Bridge, Single Girder, Underhung

Hoist)”, whichever applies.