3 end trucks – Harrington Hoists and Cranes HPC 500 End Truck User Manual

Page 14

14

3.3

End Trucks

3.3.1

Read through all steps completely before proceeding with installation.

3.3.2

All operations associated with the assembly and installation of the end trucks

and/or the crane system should be performed under the supervision of a Qualified Person (see Section

5 for the definition of Qualified Person).

3.3.3

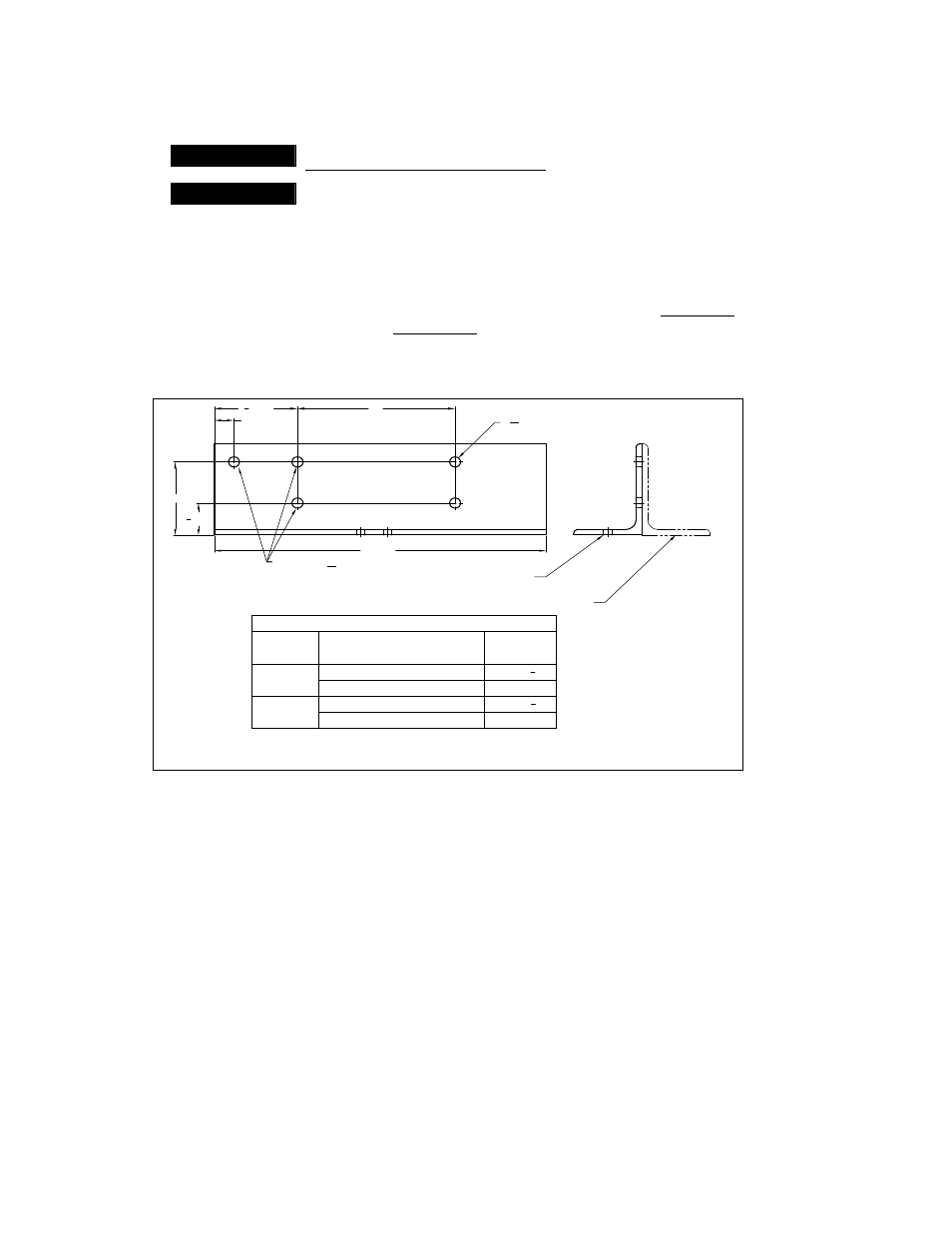

End Bracket Preparation

– Prior to assembling the end trucks prepare the four (4) end brackets (2 end

brackets per end truck) as follows:

Measure

“T” for the runway that the end trucks will be installed on. For Underhung “T” is the flange

width of the runway beam; for Top Running

“T” is the width of the rail head or square bar

(whichever is being used).

Drill tw

o 9/16” diameter holes in each of the four (4) end brackets in accordance with Figure 3-5.

4 REF.

1

3

4

REF.

1 REF.

4

1

2

REF.

17 REF.

D

EXISTING Ø

9

16

HOLES

BRACKET "A" (AS

SHOWN)

BRACKET "B" (OPPOSITE HAND)

Ø

9

16

- 2 HOLES (DRILL THESE HOLES)

FORMULA

FOR "D"

D = T + 5

D = T + 4

3

4

D = T + 5

D = T + 4

3

4

BEAM WITH FLAT FLANGE

BEAM WITH TAPERED FLANGE

RECTANGULAR SHAPED RAIL

ASCE RAIL

UNDERHUNG

TOP

RUNNING

RUNNING

SURFACE

CRANE

CONFIG.

"D" DIMENSION (INCHES)

T = I-BEAM FLANGE OR RAIL HEAD

- WIDTH MEASUREMENT

Figure 3-5 End Bracket Holes

3.3.4

Wheel Assembly Installation

– Install the Wheel Assemblies to the end trucks as shown in Figure 3-6.

Make sure you locate the Wheel Assemblies properly for your application (Underhung or Top Running)

as shown in Figure 3-7. To prevent the axle from turning when tightening the hex nut, use an air-

powered nut driver. Then, finalize the installation by applying torque to each wheel’s hex nut as follows.

75 ft-lb for HPC505

200 ft-lb for HPC510 and HPC520