Harrington Hoists and Cranes HPC 500 End Truck User Manual

Page 12

12

Table 3-1 Bridge Beams for a MANUAL or E

LECTRIC

H

OIST

on an HPC500 Crane

Important information about this table:

Includes 15% Allowance for Electric Hoist Load Factor.

Based on Harrington’s manual chain hoist product.

For spans greater than 10 ft., braces between end truck & bridge beam should be used.

Cap.

(Tons)

Maximum Allowable Span (ft)

10

15

20

24

½

S8 X 18.4

S8 X 18.4

S8 X 18.4

S10 X 25.4

1

S8 X 18.4

S8 X 18.4

S10 X 25.4

S10 X 25.4

2

S10 X 25.4

S10 X 25.4

S12 X 31.8

S12 X 31.8

C8 X 11.5

3.2.4

Fabrication

– Preparation of the Bridge Beam for assembly with the HPC500 End Trucks requires that

holes be drilled in the beam as follows. Refer to Table 2-1 and Figure 2-1 for definitions of all letter

variables used for dimensions. NOTE

– For S6 beams mounting plates must be welded to the beam.

Refer to the Bridge Beam Assembly Drawing (Underhung: Drawing. No. 62673; Top Running:

Drawing. No. 62672) for details.

Underhung

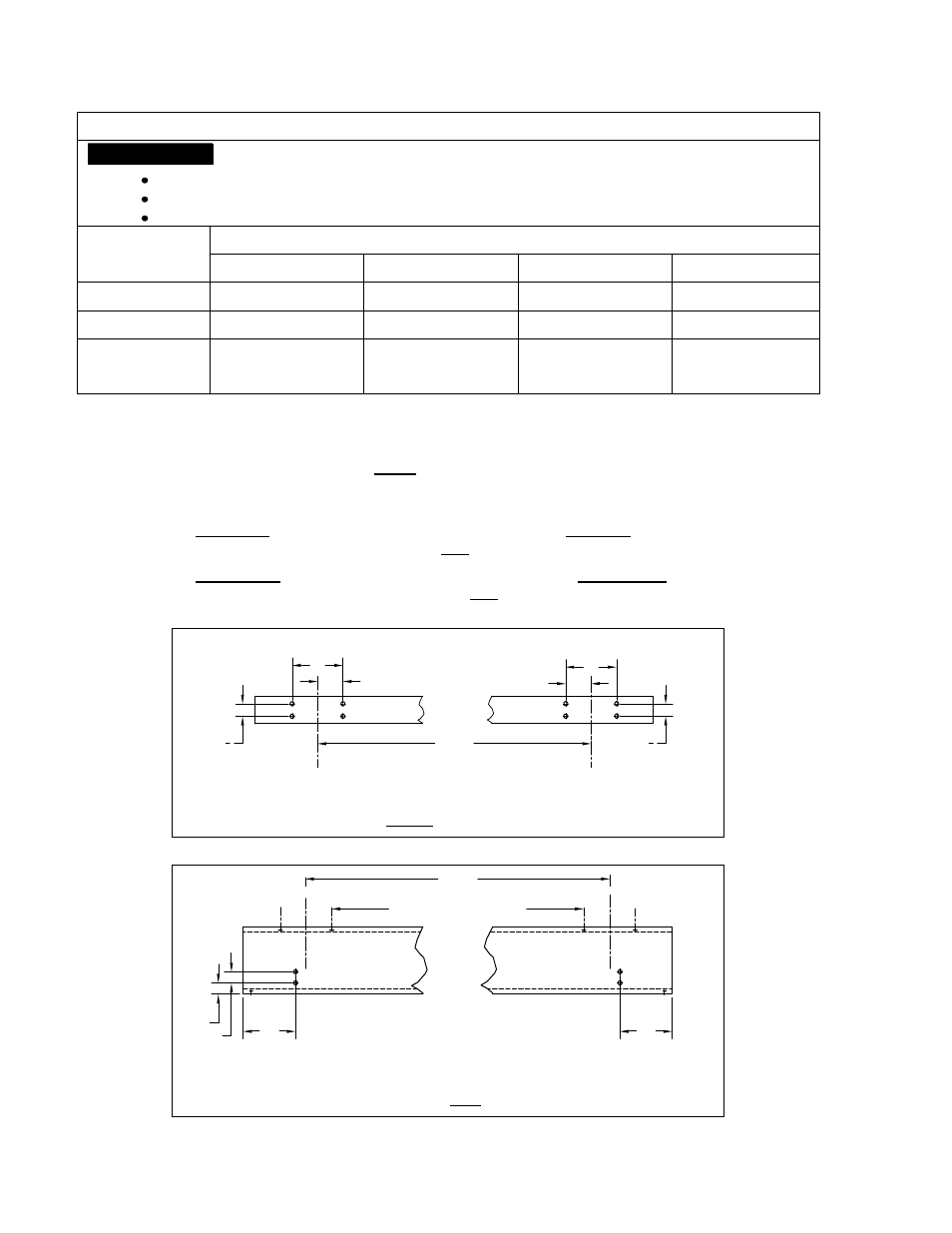

– Drill eight 9/16” diameter holes through the top flange as shown in Figure 3-1. Drill

four 9/16” diameter holes through the web as shown in Figure 3-2.

Top Running

– Drill eight 9/16” diameter holes through the bottom flange as shown in Figure 3-1.

Drill four 9/16” diameter holes through the web as shown in Figure 3-3.

2

1

4

D

2

1

4

D

SPAN

D/2

D/2

Figure 3-1 Bridge Beam Flange Holes

– U

NDERHUNG

&

T

OP

R

UNNING

10

2

2

10

BEAM FLANGE HOLES

(from Fig. 3-1)

SPAN

Figure 3-2 Bridge Beam Web Holes - U

NDERHUNG