Terminal connector torque – Gillette Generators SPMD-2500 THRU SPMD-4000 User Manual

Page 25

PAGE 25

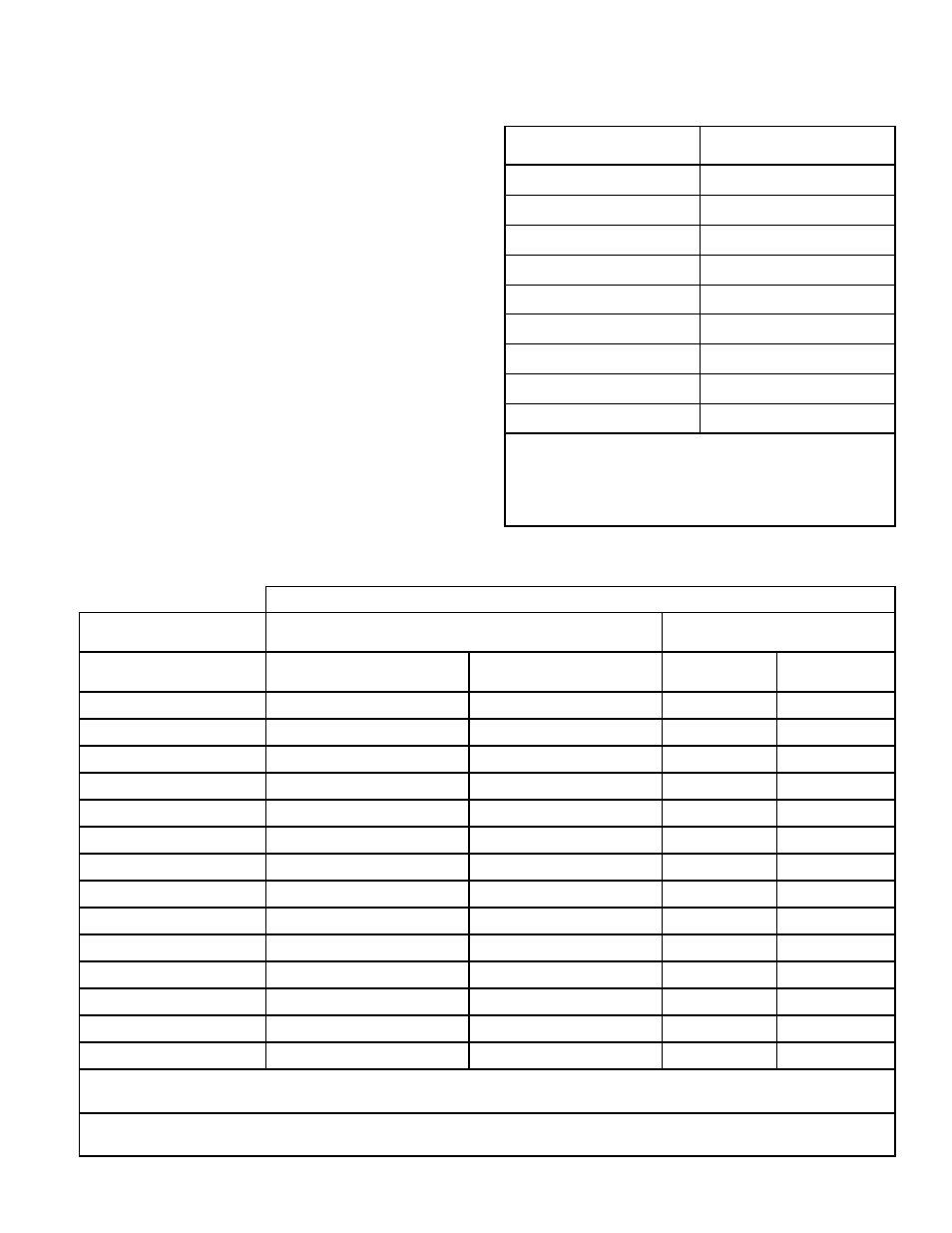

TERMINAL CONNECTOR TORQUE

Use the torque values shown for terminal connectors.

Refer to UL-486A, UL-486B, and UL0486E for

information on terminal connectors for aluminum

and/or copper conductors. Comply with applicable

national and local codes when installing a wiring

system.

NOTE: If a connector has a clamp screw such as a

slotted, hexagonal head screw with more than one

means of tightening, test the connector using both

applicable torque values.

SOCKET SIZE ACROSS FLATS,

mm (in.)

TIGHTENING TORQUE,

Nm (in. lb.)

3.2

(1/8)

5.1

(45)

4.0

(5/32)

11.4

(100)

4.8

(3/16)

13.8

(120)

5.6

(7/32)

17.0

(150)

6.4

(1/4)

22.6

(200)

7.9

(5/16)

31.1

(275)

9.5

(3/8)

42.4

(375)

12.7

(1/2)

56.5

(500)

14.3

(9/16)

67.8

(600)

NOTE: For values of slot width or length not corresponding

to those specified, select the largest torque value

associated with the conductor size. Slot width is the

normal design value. Slot length is to be measured at the

bottom of the slot.

TIGHTENING TORQUE FOR PRESSURE

WIRE CONNECTORS WITH INTERNAL-

DRIVE SOCKET-HEAD SCREWS

TIGHTENING TORQUE, Nm (in. lb)

WIRE SIZE FOR UNIT

CONNECTION

SLOT HEAD 4.7 mm (NO. 10) OR LARGER *

HEXAGONAL HEAD-EXTERNAL DRIVE

SOCKET WRENCH

AWG, kcmil (mm

2

)

SLOT WIDTH >1.2 mm (0.047 in.)

SLOT LENGTH > 6.4 mm (0.25 in.)

SLOT WIDTH >1.2 mm (0.047 in.)

SLOT LENGTH > 6.4 mm (0.25 in.)

SPLIT-BOLT

CONNECTORS

OTHER

CONNECTIONS

18-10

(0.82-5.3)

2.3

(20)

4.0

(35)

9.0

(80)

8.5

(75)

8

(8.4)

2.8

(25)

4.5

(40)

9.0

(80)

8.5

(75)

6-4

(13.3-21.2)

4.0

(35)

5.1

(45)

18.6

(165)

12.4

(110)

3

(26.7)

4.0

(35)

5.6

(50)

31.1

(275)

16.9

(150)

2

(33.6)

4.5

(40)

5.6

(50)

31.1

(275)

16.9

(150)

1

(42.4)

-

5.6

(50)

31.1

(275)

16.9

(150)

1/0-2/0

(53.5-67.4)

-

5.6

(50)

43.5

(385)

20.3

(180)

3/0-4/0

(85.0-107.2)

-

5.6

(50)

56.5

(500)

28.2

(250)

250-350

(127-177)

-

5.6

(50)

73.4

(650)

36.7

(325)

400

(203)

-

5.6

(50)

93.2

(825)

36.7

(325)

500

(253)

-

5.6

(50)

93.2

(825)

42.4

(375)

600-750

(304-380)

-

5.6

(50)

113.0

(1000)

42.4

(375)

800-1000

(406-508)

-

5.6

(50)

124.3

(1100)

56.5

(500)

1250-2000

(635-1016)

-

-

124.3

(1100)

67.8

(600)

* For values of slot width or length not corresponding to those specified, select the largest torque value associated with the

conductor size. Slot width is the normal design value. Slot length is to be measured at the bottom of the slot.

NOTE: If a connector has a clamp screw such as a slotted, hexagonal head screw with more than one means of tightening, test

the connector using both applicable torque values.

TIGHTENING TORQUE FOR SCREW-TYPE PRESSURE WIRE CONNECTORS