Cooling the generator, Muffler mounting to generator, Radiator coolant capacity – Gillette Generators SPMD-2500 THRU SPMD-4000 User Manual

Page 16: Including engine block)

PAGE 16

F) The exhaust piping system is subject to engine

vibration, so it must be solidly installed to reduce

potential for pipe cracks or breakage.

G) It is very important to discharge exhaust gasses

away from the engine and out of the generator

building. If these gasses remain in the engine

cylinders, poor engine performance and eventual

engine damage may result. This condition usually

results from excessive back-pressure, which can

result from:

1) Exhaust pipe diameter is too small or exhaust

system is too long.

2) Excessive amount of bends in exhaust pipe run.

3) Obstructions (old birds nest, bees, insects, etc.)

in the exhaust system.

All three items are examples that will cause back

pressure that MUST NOT EXCEED 20”/WATER

COLUMN.

Mufflers are shipped loose on all “Open” (no

enclosure) generator sets. Mufflers with weight up to

52 pounds can be attached directly to the engine

exhaust manifold pipe (See drawing on page 15).

Mufflers more than 52 pounds are too heavy for

mounting directly to manifold pipe. These heavier

muffler will require separate support structure. The

flexible exhaust pipe can be mounted to the engine

manifold pipe with additional piping to the ceiling

(roof) structure, where muffler can be suspended.

COOLING THE GENERATOR

This manual explains the use of engine mounted

radiators, as the only cooling method used for

GILLETTE generators. Environmental issues require

cleaner burning engine. Engine manufacturers have

raised engine operating temperatures in order to

reduce

exhaust

emissions

and

improve

fuel

economy.

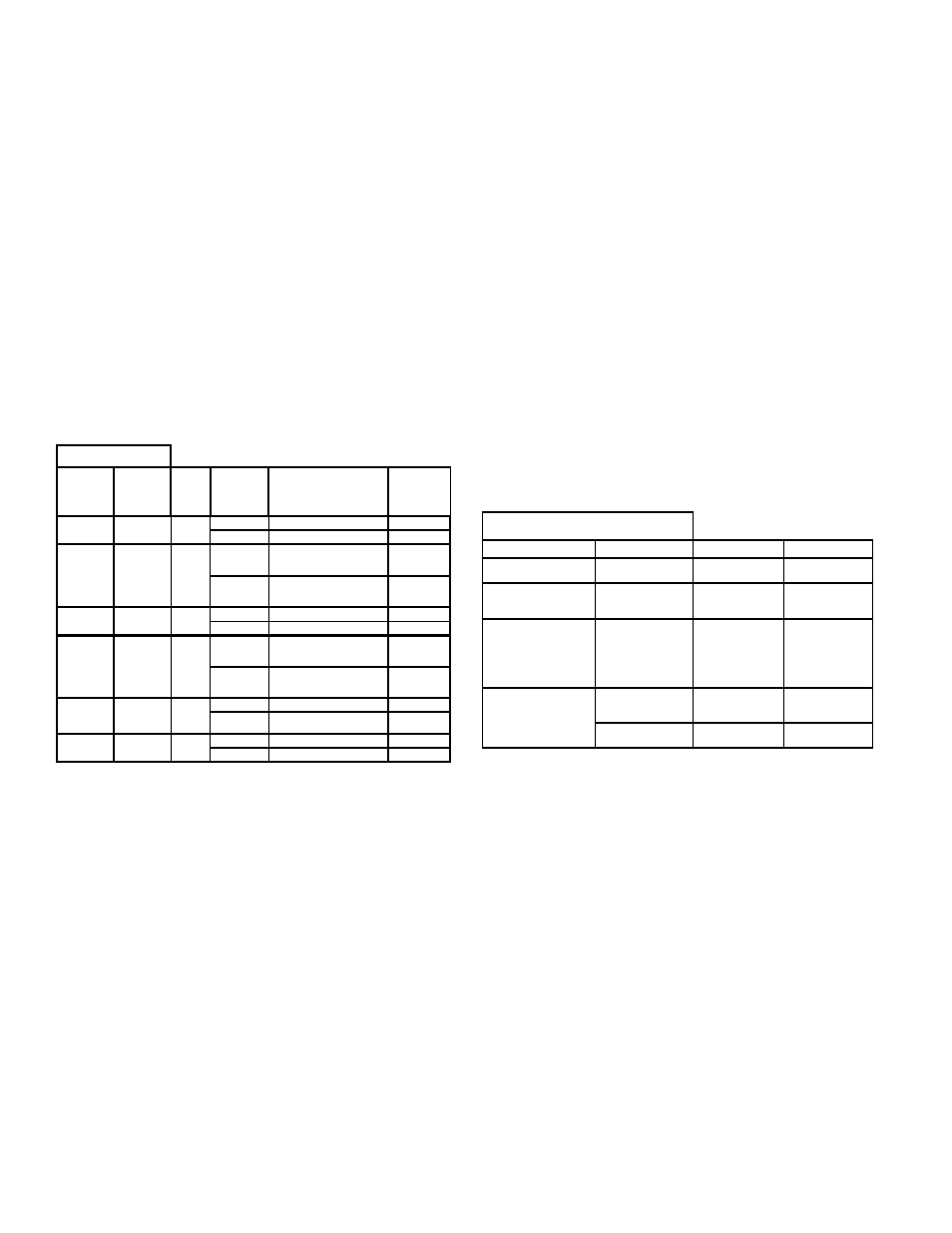

MUFFLER MOUNTING TO GENERATOR

GENERATOR MODEL

JOHN

DEERE

DRIVEN

FIAT

DRIVE

PIPE

SIZE

COWL

MODEL

MUFFLER

DESCRIPTION

NET

WEIGHT

LBS.

SPJD-250

SPJD-300

2”

CR-2”

RESIDENTIAL GRADE

15

CC-2”

CRITICAL GRADE

19

SPJD-420

SPJD-520

SPJD-600

2 ½”

CR-2 ½”

RESIDENTIAL GRADE

20

CC-2 ½”

CRITICAL GRADE

32

SPJD-800

SPJD-1000

3”

CR-3”

RESIDENTIAL GRADE

32

CC-3”

CRITICAL GRADE

52

SPJD-1250

SPJD-1550

SPJD-1800

SPJD-2100

3½”

CR-3½”

RESIDENTIAL GRADE

38

CC-3½”

CRITICAL GRADE

63

SPMD-2500

SPMD-2800

SPMD-3000

5”

CR-5”

RESIDENTIAL GRADE

74

CC-5”

CRITICAL GRADE

98

SPMD-3500

SPMD-4000

6”

CR-6”

RESIDENTIAL GRADE

94

CC-6”

CRITICAL GRADE

137

Today’s engines run on the borderline of over.

heating, with in-cylinder temperatures close to 2000º.

GILLETTE uses a 50/50 mix of glycol/di-ionized

water. When we know generator destination is in

colder climates such as Northern USA, Canada, or

Alaska, a 60/40 mix is used. When replacing coolant

in radiator DO NOT USE a 50% glycol and 50% tap

water. Tap water contains minerals, dissolved

oxygen, and chorine, which will cause scaling and

corrosion in the engine. Always use a mixture of

glycol and de-ionized water or distilled water, never

use tap water. Radiators of today’s design are

extremely fragile and light weight, containing

smaller cooling tubes and ,more cooling fins, so it

has become easier to clog radiators with corrosive

coolants. GILLETTE, the radiator manufacturer, and

engine block manufacture will decline warranty on

clogged radiator and engine block problems when it

is known that tap water is used rather than distilled

water.

When coolant system is drained and fresh coolant is

added, it’s best to use a hydrometer for testing the

value of antifreeze mixture. A correct 50/50 mix

allows freeze protection to –34º F and boil-over

protection to 265º F.

COOLING THE GENERATOR AND

ENGINE THAT IS MOUNTED IN A

GENERATOR ROOM

Whenever an open (no housing) generator set is

installed inside a room, in a building the radiator

should be ducted outside the room. See Figure 5,

page 14.

The most common method of generator set cooling,

is that of a generator mounted radiator. The major

components are:

RADIATOR COOLANT CAPACITY

(INCLUDING ENGINE BLOCK)

GENERATOR MODEL

JOHN DEERE DRIVEN

FIAT DRIVE

QUARTS

LITERS

SPJD-250

SPJD-300

9.16

8.6

SPJD-420

SPJD-520

SPJD-600

13.0

12.2

SPJD-800

SPJD-1000

SPJD-1250

SPJD-1550

SPJD-1800

SPJD-2100

37.0

35.0

SPMD-2500

SPMD-2800

SPMD-3000

67.0

63.4

SPMD-3500

SPMD-4000

71.7

67.9