Diesel fuel consumption by model at full load – Gillette Generators SPMD-2500 THRU SPMD-4000 User Manual

Page 24

PAGE 24

specifics on fuel information.

OPTIONAL DIESEL TANK

CONSIDERATIONS

1) A flexible fuel line must be used at connection

point on the diesel engine (option)

2) Five (5) gallon spill/fill container.

3) A 2” overfill valve.

4) Rain slant on tank cover.

5) Immersion heater for operation below 50º F (10º C).

STANDARD FUEL TANK EQUIPMENT

1) Emergency venting to UL standards.

2) Rupture tank switch.

3) Normal vent, 2” NPT with 10” extension.

4) Locking fuel cap, 2” NPT with 10” extension.

5) Visual, mechanical level gauge.

6) Fuel supply and return lines, 1/2” diameter.

7) Low fuel level switch at 50% setting.

8) Double wall heavy duty, 7 gauge steel, “Leak-

Proof” construction.

9) Fuel drain with 1/2” NPT plug.

10) Powder coat finish with oil fog interior.

AREAS REQUIRING SPECIAL

DIESEL TANKS

Many states and Regions have specific requirements,

for fuel tanks. During tank installation planning,

check with local building authorities, local Fire Chief,

or other regional authorities. Known areas

requesting special diesel tank equipment are: The

States of Florida, Michigan, and Washington, plus

areas of New York City, Chicago, and Los Angeles.

DAY TANKS

All GILLETTE diesel fuel tanks are designed to fit

underneath generator set. Special precautions are

required to lift these two parts, now considered one

assembly, and at much heavier total weight.

If fuel tank is shipped loose from generator set, for

purpose of mounting tank remotely from generator, a

separate diesel fuel “Day Tank” may be required.

There are small 5-10 gallon tanks to allow fuel to

immediately reach engine, rather than having engine

crank at longer intervals, to get fuel finally to reach

engine.

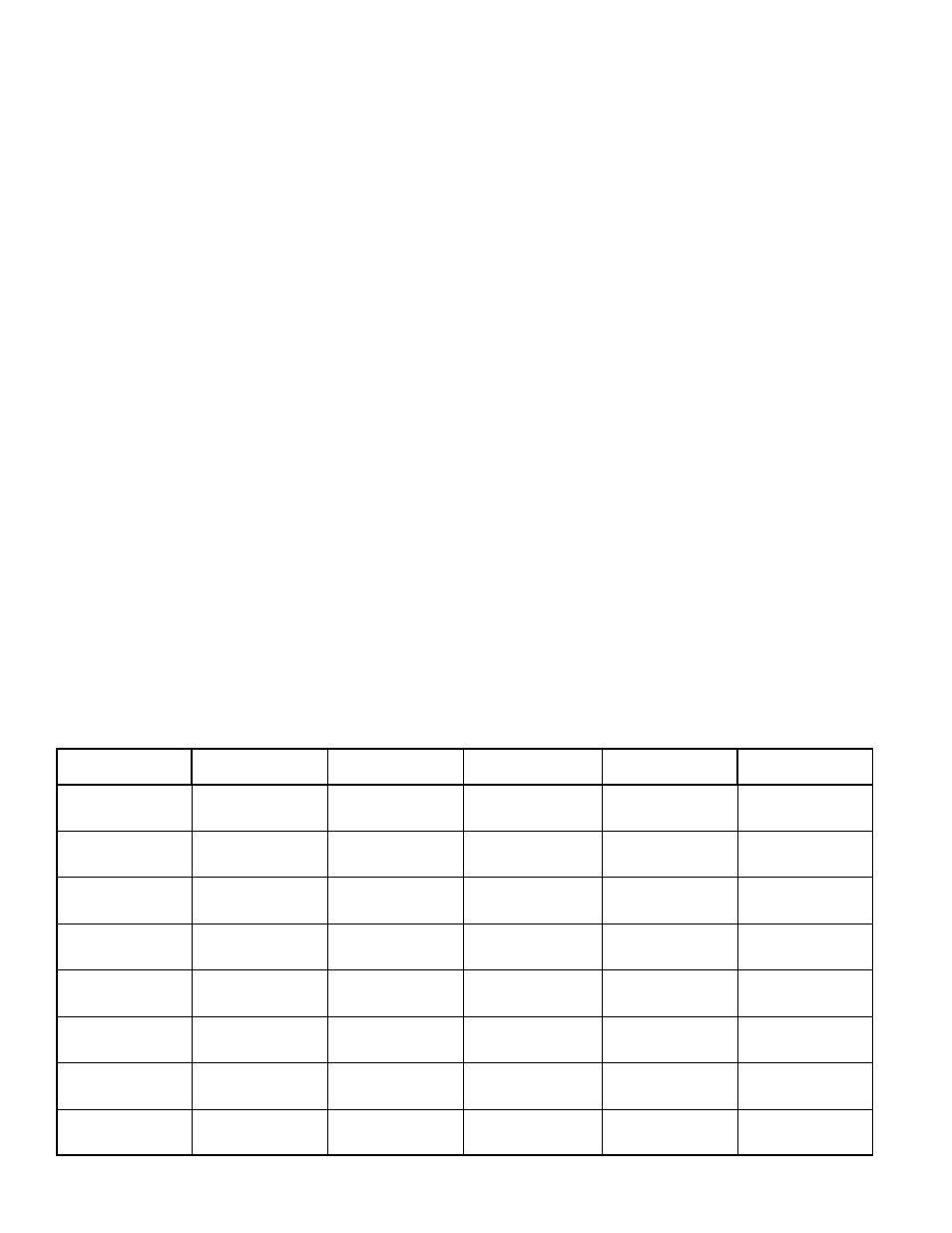

DIESEL FUEL CONSUMPTION BY MODEL AT FULL LOAD

MODEL NO. 60 HZ GAL/HR

50 HZ L/HR

MODEL NO.

60 HZ GAL/HR

50 HZ L/HR

SPJD-250

2.2

8.3

SPJD-1550

12.1

45.8

SPJD-300

2.8

10.6

SPJD-1800

13.6

51.5

SPJD-420

3.75

14.2

SPJD-2100

15.5

58.7

SPJD-520

4.4

16.7

SPMD-2500

17.8

67.4

SPJD-600

5.0

18.9

SPMD-2800

19.5

73.8

SPJD-800

6.6

25.0

SPMD-3000

20.4

77.2

SPJD-1000

7.9

30.0

SPMD-3500

26.1

98.8

SPJD-1250

9.3

35.1

SPMD-4000

28.0

105.9