Maintenance – Fulton Edge ICX or FB-F Vertical Tubeless Boilers (Steam), Gas Fired User Manual

Page 68

59-G 1/01

Maintenance

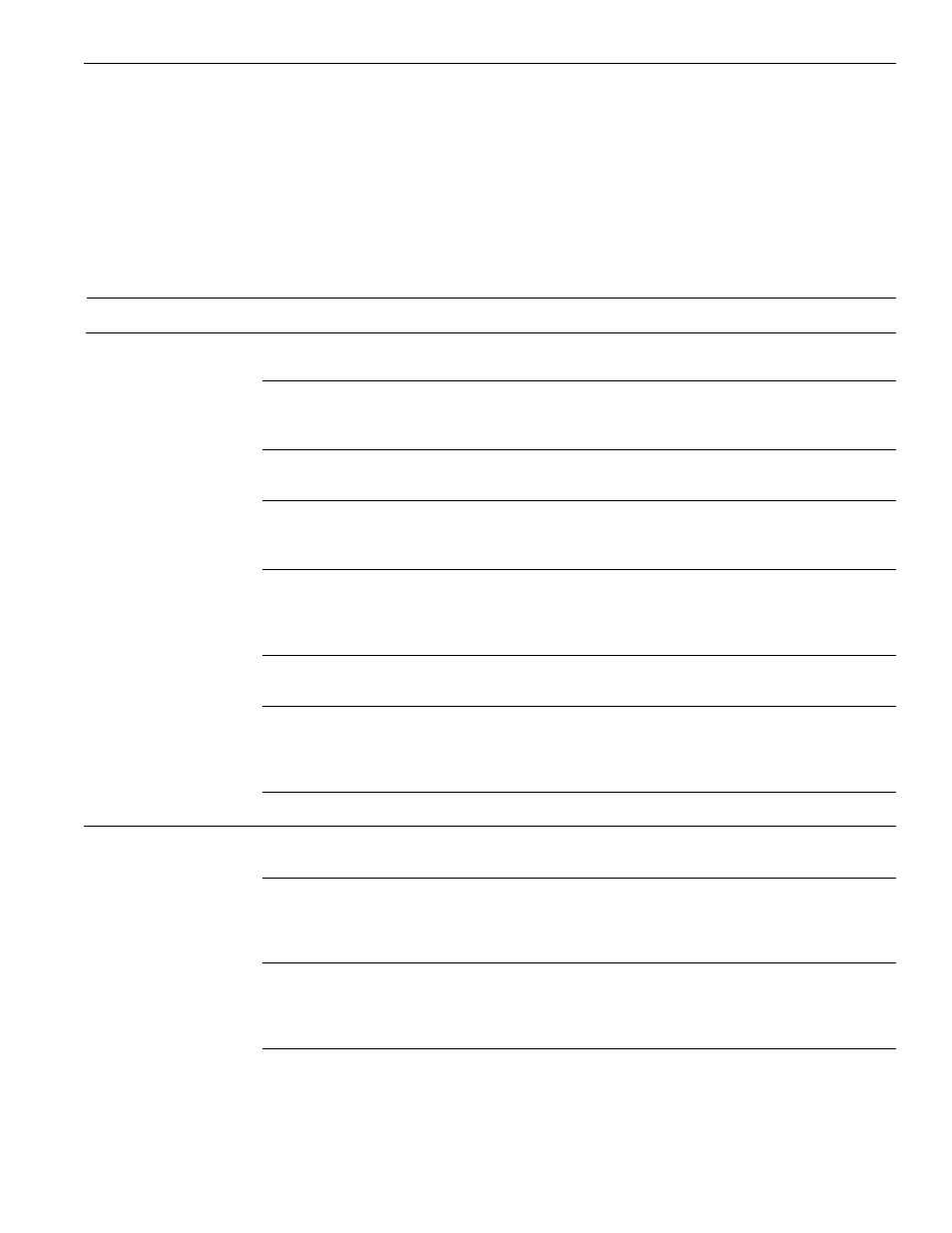

Troubleshooting

a) The following trouble shooting

guide will assist in the diagnosis and

the correction of minor field prob-

lems. It contains instructions and

information necessary to locate and

isolate possible troubles which

occur during normal operation. It

should be used in conjunction with

the unit wiring diagram and the

component literature provided in

Section 7 of this manual.

b) The following lists cover the most

common troubles that may occur on

the Fulton gas fired boilers. Refer to

left hand column of the chart to

locate the problem. Determine

which cause, listed in the center col-

umn, that represents the problem by

performing the corrective action as

listed in the right hand column titled

“REMEDY”.

Troubleshooting Gas-Fired Boilers

Problem

Cause

Remedy

Ignition Failure

1. Power Supply

Check fuse or circuit breaker. Reset or

replace, as necessary.

2. Ignition Electrodes

Check electrodes for carbon buildup and

clean if necessary. Check for proper adjustment. Readjust

if necessary. Check for cracks in porcelain. If found,replace.

3. Transformer

Check voltage between transformer leads at

terminal block to be sure transformer is being powered.

4. Flame Safeguard

Check voltage between ignition terminal and neutral.

Control

Check must be made before control locks out on safety.

If no power, replace control.

5. Faulty Air Switch

Check for bad air switch by jumpering the two air switch

leads at the terminal block. If the boiler starts and runs

with these terminals jumpered, the air switch should

be replaced.

6. Gas Valve Sticking

Check for dirt in valve or orifice and clean if necessary.

(Pilot)

Check for faulty actuator or valve and replace if necessary.

7. Gas Supply*

Check for gas pressure and for intermittent supply

problems. Gas pressure for natural gas should be

3-1/2" W.C. plus fan pressure at the elbow to the

burner and 7" to 11" W.C. at the head of the train.

8. Loose wire connection

Check connections to all components.

Flame Failure

1. Power Supply

Check fuse or circuit breaker. Reset or replace, as

necessary.

2. Gas Supply*

Check for gas pressure and for intermittent supply

problems. Gas pressure for natural gas should be

3-1/2" W.C. plus fan pressure at the elbow to the

burner and 7" to 11" W.C. at the head of the train.

3. Ignition Electrodes

Check electrodes for carbon buildup and clean

if necessary. Check for proper adjustment.

Readjust if necessary. Check for cracks in

porcelain; if found, replace.

4. Primary Air Adjustment

Check air adjustment. Air may be blowing flame

away from flame rod.

* For natural gas fired boilers. Refer to the test fire sheet for all other fuels.