Punching 3, And 4" holes – Gardner Bender Hydraulic Knockout Sets User Manual

Page 3

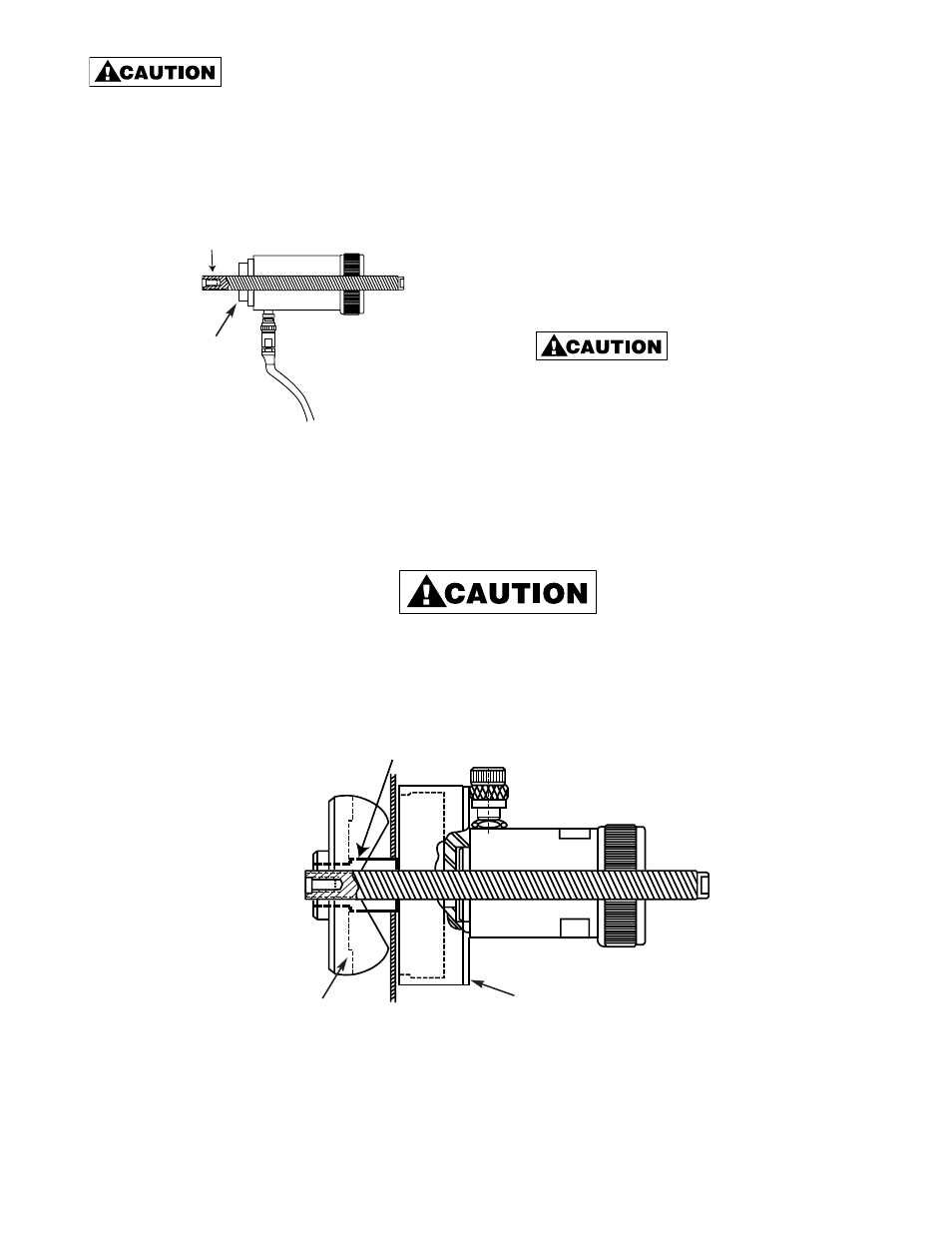

Pull Rod

Converter

To avoid excessive wear and tear on the pull rod threads

during punching, center the pull rod accurately so that it

does not rest against the metal edge of the guide hole.

Also, be sure that all points of the punch are in uniform

contact with the metal surface when starting to punch.

Figure 6

NOTE: It will be necessary to turn the pull rod until it

extends further beyond the cylinder (coupler end).

Punching 3

1

⁄

2

" and 4" Holes

1. Larger punch sizes require a 1

15

⁄

16

” diameter

guide hole (use 1

1

⁄

2

” punch and die) and a

KC3540 converter.

2. Drill a

7

⁄

16

” pilot hole in the metal. Use the 1

1

⁄

2

” punch

and die set to make the guide hole. See paragraph

“Punching holes

3

⁄

4

” through 3”.

3. Remove the 1

1

⁄

2

” punch and die. Install the 3

1

⁄

2

”,

4”, 5”, or 6” die over the pull rod. (See Figure 7)

4. Install the KC3540 converter on the inside of the

punch. (Figure 7)

Do not install the converter (KC3540) on outside of

punch. Damage to the pull rod would result from

incorrect converter installation.

5. Place the pull rod into the guide hole. Install the

punch on the pull rod and turn until the converter is

into the guide hole.

6. Close the pump release valve. Work the pump handle

until all points of the punch completely penetrate the metal.

The converter requires a 1

15

⁄

16

” diameter or larger guide hole (use the 1

1

⁄

2

” knockout).

Do not assemble converter on outer side of punch, or pull rod will bend during operation.

Figure 7

Punch

Die

Die

3