Gardner bender, Viii. maintenance – Gardner Bender BV208DA User Manual

Page 12

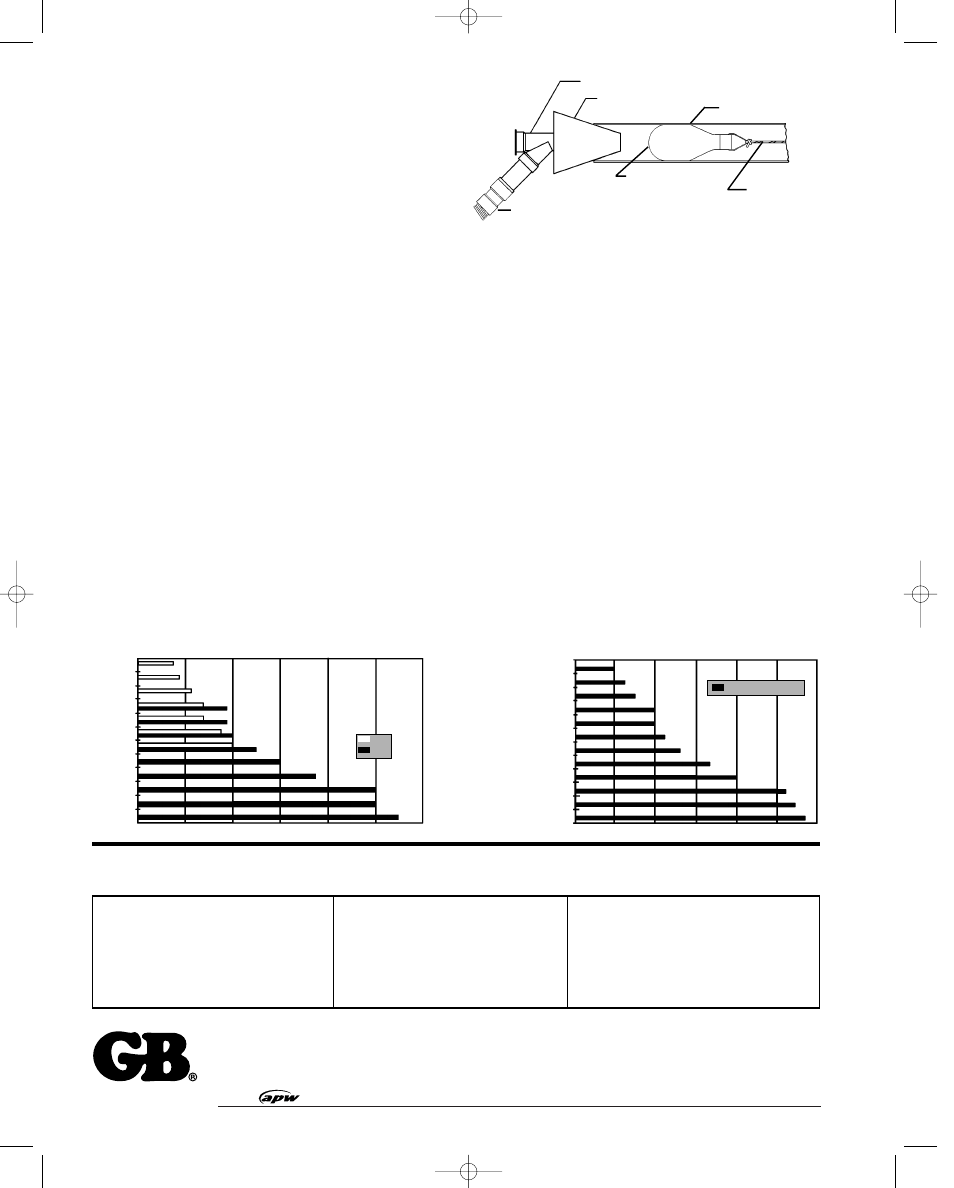

Vacuuming Pull Line in the Conduit

1.

Insert the hose in the vacuum port.

2.

Select the JV07 small Dial-A-Line™ body that

accepts the JV08, JV09 or JV12 Seal-off for conduit

sizes

1

⁄

2

” through 2

1

⁄

2

” or the B26 Large Dial-A-

Line™ body that accepts the BV23 or BV24 Seal-off

for conduit sizes 1

1

⁄

4

” through 6”.

3.

Connect the hose to the Dial-A-Line™ body.

4.

Place the pull line at the far end of the conduit.

5.

Select the appropriate line carrier and tie the pull line

securely to the line carrier.

6.

Insert the line carrier in the conduit and turn on the

power unit.

VIII. Maintenance

The Blowers and Blo-Vac™ systems should require very

little maintenance. If the unit should require service, see

instructions below.

Blower overheating occurs when attempting to blow line

in blocked conduit or a duct filled with water having a

head greater than the water lift capability of the blower.

See Table 1.

The 1261 and B3000 Blowers have an automatic thermal

overload switch built into the motor. If overheating

occurs, the switch will turn the motor off. After a cool-

down period of 15 to 30 minutes, the motor will

automatically re-set. The motor can be restarted.

Blo-Vac™ power units are equipped with a perforated

filter screen, located on the under side of the motor

compartment. Occasionally the screen becomes clogged

with lint and dust and it should be cleaned to maintain

maximum air flow.

Vacuuming Dirt and Water — Each Blo-Vac™ comes

with a cloth filter bag that must be used when vacuuming

dirt and water. Use as follows:

1. Release the latches securing the top and center

together.

2. Remove the filter bag from the bottom tool storage

section. Slide the filter bag onto the intake canister

located on the bottom of the motor. The filter bag

prevents dust from entering the motor. Dust and dirt

will damage the motor and cause premature failure.

3. After use, clean the filter bag by shaking off the

excess dirt and store the clean bag in the lower

compartment.

4. The Blo-Vac™ is equipped with a ball float to

prevent water from entering the motor. If the ball

float seals the motor inlet, the motor will sound

different from usual. Immediately turn the unit off.

Empty the recovery section and check the inlet

screen for lint and dirt. Clean and reassemble the

Blo-Vac™ sections.

B26 Dial-A-Line Body

BV24 Seal-Off

Conduit

Pull

Line

Inflatable

12568 Hose Assembly

Vacuuming Line in Conduit

with the Inflatables

®

Blower Application

Blo-Vac Application

1/2”

3/4”

1”

1 1/4”

1 1/2”

2”

2 1/2”

3”

3 1/2”

4”

5”

6”

1/2”

3/4”

1”

1 1/4”

1 1/2”

2”

2 1/2”

3”

3 1/2”

4”

5”

6”

B45

B60

BV208DA

0

200

400

600

800

1000

1200

0

200

400

600

800

1000

1200

Distance

Size Conduit

Size Conduit

WARRANTY: GB ELECTRICAL, INC. warrants its

product against defects in workmanship and materials

for 1 year from date of delivery to user. Chain is not

warranted. Warranty does not cover ordinary wear

and tear, abuse, misuse, overloading, altered products

or use of improper fluid.

WARRANTY RETURN PROCEDURE: When question

of warranty claim arises, send the unit to the nearest GB

Authorized Service Center for inspection, transportation

prepaid. Furnish evidence of purchase date. If the claim

comes under the terms of our warranty the Authorized

Service Center will REPAIR OR REPLACE PARTS

AFFECTED and return the unit prepaid.

PARTS AND SERVICE: For quality workmanship and

genuine GB ELECTRICAL parts, select an Authorized

GB Service Center for your repair needs. Only repairs

performed by an Authorized Service Center displaying

the official GB Authorized sign are backed with full

factory warranty. Contact GB Electrical (414)352-4160

for the name of the nearest GB Authorized

Service Center.

REPAIR AND SERVICE INSTRUCTIONS: For repair service and parts contact your nearest GB ELECTRICAL Service Center. The GB

ELECTRICAL Service Center will provide complete and prompt service on all GB ELECTRICAL products.

Gardner

Bender

6101 N. Baker Road, Milwaukee, WI 53209 • Phone: (414) 352-4160 • FAX (414) 352-2377

ZRPS-0134 12/98

a unit of Tools and Supplies

RPS-0134 3/29/00 2:10 PM Page 12