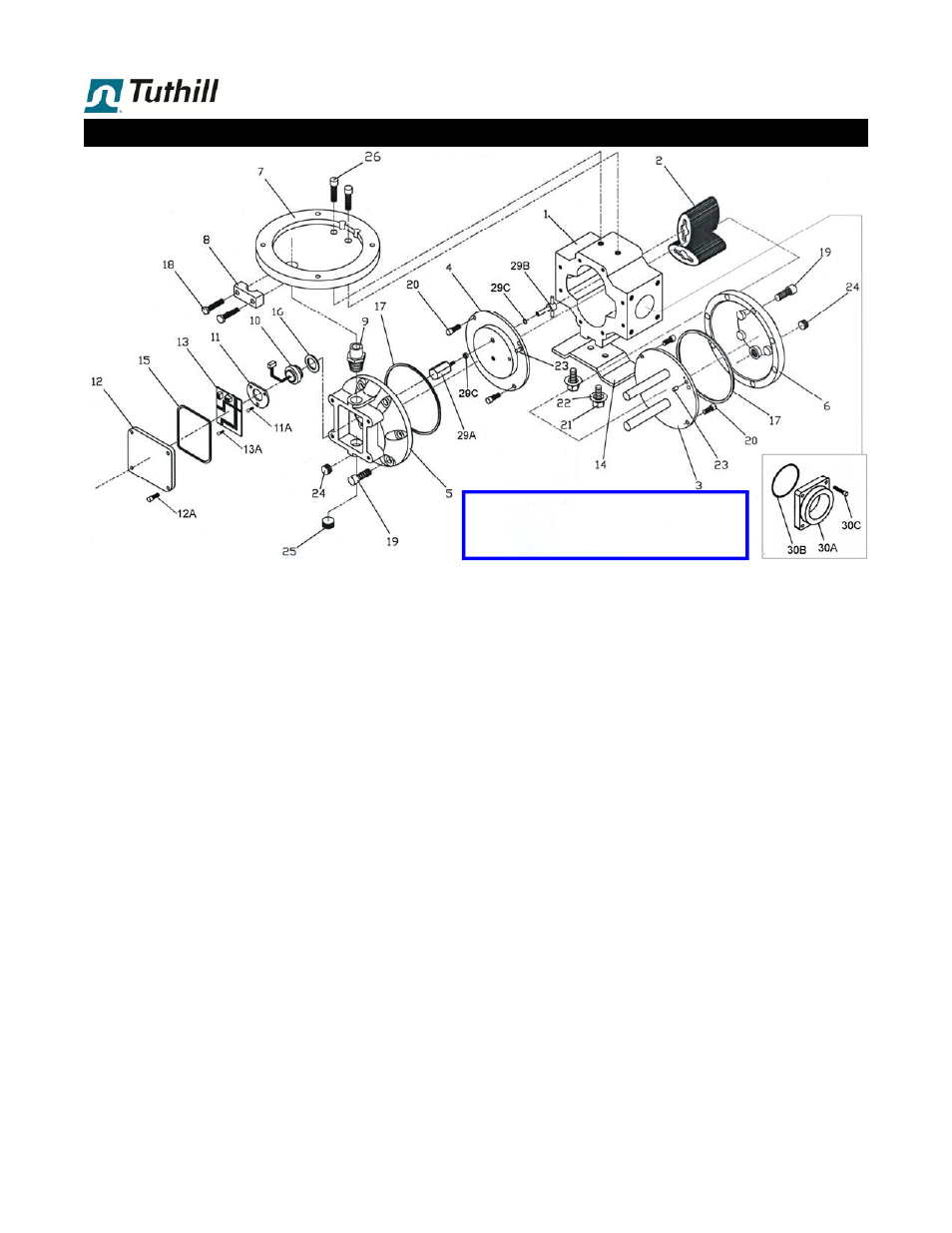

Flow meter - disassembly – Fill-Rite TS SS F & W Precision Meter User Manual

Page 18

4. Remove 4 screws (20) from bearing plate assembly (4),

and pull the bearing plate off the meter body. If the bear-

ing plate is stuck to meter body, gently tap with a rubber

mallet, or use a 5/16-8 x 1” jack bolt to push it free.

5. Inspect inside of bearing plate (4) for scoring (minor

markings is acceptable). If the bearing plate is scored, it

should be replaced

6. Verify that the drive shaft (29A) for the magnet assembly

is turning smoothly.

6.1 If it wobbles, replace bearings (2 x 29B).

6.2 If the drive shaft is worn,

replace magnet drive assembly (29A, B & C).

7. Before removing oval gears, mark across both gears (2)

with a soft pencil for alignment during re-assembly.

7.1 Extract the gears, and inspect for wear or damage.

Replace

if

necessary.

7.2 Inspect the interior of the measuring chamber and

the post plate assembly for wear or damage. Re-

move any deposits using a fine emery cloth, or fine

wire brush; be careful not to score or damage any of

the internal parts.

7.3 If posts, or post plate, are worn, the complete

assembly must be replaced. To replace, see D.

Reassemble in reverse order:

Align oval gears on mark made prior to disassembly.

Installing new gears, the lower gear must be at 90° to

the upper gear, when the upper gear is horizontal.

Make sure that the gears turn freely on the shafts, and

do not rub or bind against the housing (1). Nor should

there be excessive clearance. Leave the top gear with

the slot for the coupling (29A) in horizontal position

.

Re-attach the bearing plate (4) with coupling/magnet

(29) in the up position. Align with dowel pins, and

1 . 18

Flow Meter - Disassembly

A. Pulser O-ring (16), or Pulser (10)

First relieve system pressure and drain the flow meter.

1. Remove 4 screws (12a) from the dust cover (12), and

detach the dust cover.

2. Release signal cable from TB1 on the board (13).

3. Release pulser (10) leads from

J1

on terminal block

board/SCL (13).

4. Remove 2 terminal block board/SCL screws (13a), and

take the board (13) out. Place on a clean & dry surface.

5. Remove 3 retainer screws (11a), and detach the retainer

(11). The pulser (10) can now be removed, so the O-ring

(16) can be replaced.

Reassemble in reverse order, checking all O-ring seals

for damage. Teflon O-rings must be replaced whenever

the flow meter has been opened.

B. Bearing Plate (4)

C. Oval Gears (2)

First relieve system pressure and drain the flow meter.

In a W●● flow sensor with remote register, items 7, 8, 9, 18

& 26 are not included. Here the front cover can be removed

directly for access to flow meter internals after signal cable

has been disconnected. In an F●● flow meter with register,

remove the two screws (18) from the clamp (8) and take the

clamp off - leaving the register in place on the flow meter.

1. Remove 4 screws (12a) from the dust cover (12), and

detach the dust cover.

2. Release signal cable from TB1 on the board (13).

3. Remove cover screws (19) from the front cover, and slide

the cover off the flow meter (downwards), leaving the

register in place on the flow meter. Be careful that the

plug on the output cable slips up through the stand-off (9);

if the plug catches on the edge, it might pull off.

When servicing meters with Teflon

seals, replace all seals every time

the flow meter is serviced.