5. replacing gun contact tip, 6. changing drive roll and wire inlet guide, 7. welding troubleshooting table – Hobart Welding Products BETA-MIG 1800 User Manual

Page 25

OM-929 Page 21

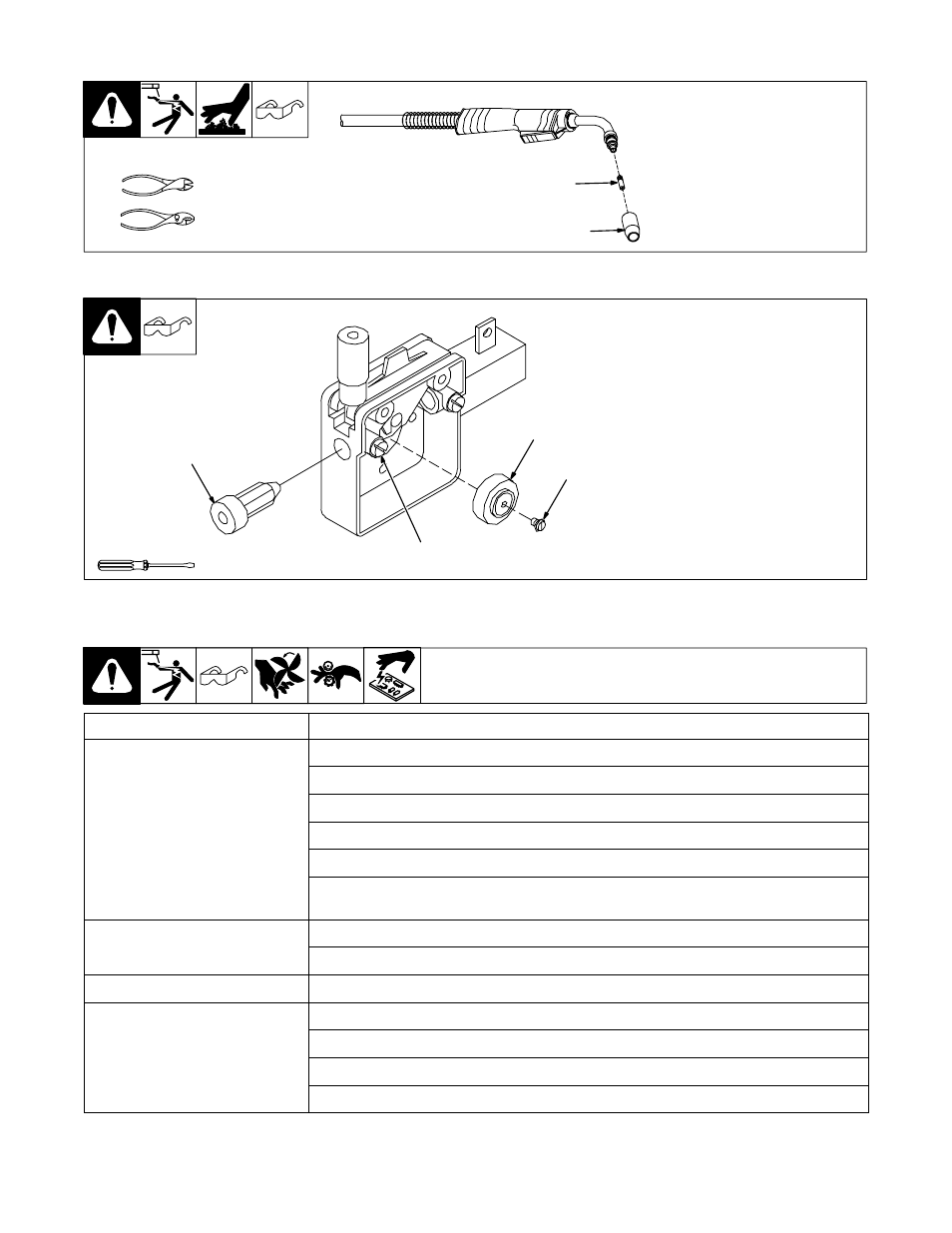

4-5.

Replacing Gun Contact Tip

Ref. 800 797-C

Y

Turn Off unit.

1

Nozzle

2

Contact Tip

Cut off welding wire at contact tip.

Remove nozzle.

Remove contact tip and install new

contact tip. Reinstall nozzle.

1

2

Tools Needed:

4-6.

Changing Drive Roll And Wire Inlet Guide

Ref. ST-801 875

1

Inlet Wire Guide Securing

Screw

2

Inlet Wire Guide

Loosen screw. Slide tip as close to

drive rolls as possible without

touching. Tighten screw.

3

Drive Roll

Install correct drive roll for wire size

and type.

4

Drive Roll Securing Screw

Secure drive roll with screw as

shown.

Tools Needed:

2

1

3

4

4-7.

Welding Troubleshooting Table

Welding Trouble

Remedy

No weld output; wire does not feed.

Secure power cord plug in receptacle (see Section 2-10).

Check and replace power switch if necessary.

Check circuit breakers CB1 and/or CB2, and reset if necessary (see Section 4-2).

Replace building line fuse or reset circuit breaker if open (see Section 2-10).

Secure gun plug in receptacle or repair leads, or replace trigger switch (see Sections 2-4 and 4-4).

Thermostat TP1 open (overheating). Allow fan to run; the thermostat will close when the unit has cooled

(see Section 2-2).

No weld output; wire feeds.

Connect work clamp to get good metal to metal contact.

Replace contact tip (see Section 4-5).

Low weld output.

Connect unit to proper input voltage or check for low line voltage (see Section 2-10).

Low, high, or erratic wire speed.

Readjust front panel settings (see Section 3-1).

Change to correct size drive roll (see Section 4-6).

Readjust drive roll pressure (see Section 2-11).

Replace inlet guide, contact tip, and/or liner if necessary (see Section 4-6).