2. weld parameters – Hobart Welding Products BETA-MIG 1800 User Manual

Page 21

OM-929 Page 17

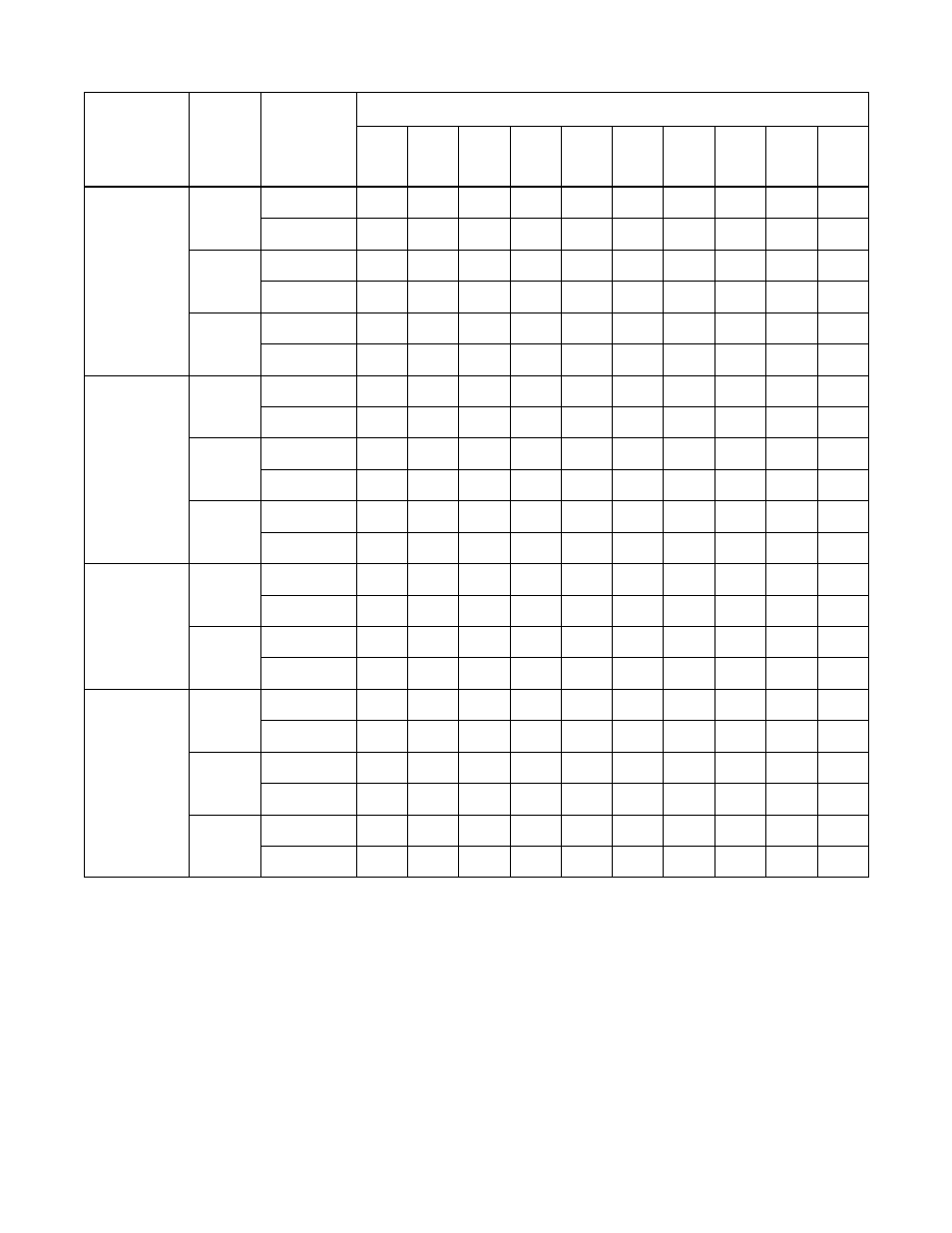

3-2.

Weld Parameters

Material Thickness

Wire Type,

Shielding Gas,

And Flow Rate

Wire

Diameter

(inch)

Operator

Controls

3/8 in

(9.5

mm)

1/4 in

(6.4

mm)

3/16 in

(4.8

mm)

1/8 in

(3.2

mm)

12 ga

14 ga

16 ga

18 ga

20 ga

22 ga

Voltage Tap

– –

6

5

4

3

3

2

2

1

1

.023

Wire Speed

– –

100

80

65

55

45

35

25

15

5

E70S-6

Voltage Tap

6

5

4

3

3

2

2

1

1

– –

CO

2

20 cfh+

.030

Wire Speed

80

70

60

55

45

35

25

15

5

– –

Voltage Tap

6

5

4

3

3

2

2

2

– –

– –

.035

Wire Speed

70

60

50

45

40

30

20

10

– –

– –

Voltage Tap

– –

5

4

3

3

2

2

1

1

1

.023

Wire Speed

– –

90

80

70

60

50

40

35

25

12

E70S-6

75% Argon

Voltage Tap

6

5

4

3

3

2

2

1

1

1

75% Argon

25% CO

2

20 cfh+

.030

Wire Speed

85

75

65

55

50

45

35

20

5

0

20 cfh+

Voltage Tap

6

5

4

3

3

2

2

1

1

– –

.035

Wire Speed

80

70

60

45

40

30

20

10

0

– –

Voltage Tap

6

5

5

4

4

3

2

1

– –

– –

E71T-GS

.030

Wire Speed

80

70

65

55

50

30

20

10

– –

– –

E71T-GS

Flux Core

Voltage Tap

6

5

4

3

3

2

1

– –

– –

– –

.035

Wire Speed

60

50

40

30

25

20

10

– –

– –

– –

Voltage Tap

5

4

4

4

3

3

3

2

2

2

.023

Wire Speed

95

85

80

60

50

50

50

30

20

20

ER 308

Stainless Steel

90% HE /

Voltage Tap

5

5

4

3

3

2

2

2

1

– –

90% HE /

7.5% Argon /

2.5% CO

2

.030

Wire Speed

70

70

70

50

45

50

45

40

0

– –

2

20 cfh+

Voltage Tap

6

5

5

4

3

2

2

2

– –

– –

.035

Wire Speed

65

40

40

30

30

25

20

10

– –

– –

*Do not change Voltage switch position while welding. Wire Speed is a starting value only, and can be adjusted while welding. Weld conditions also

depend on other variables such as stickout, travel speed, weld angle, cleanliness of metal, etc.