9. electrical service guide – Hobart Welding Products BETA-MIG 1800 User Manual

Page 17

OM-929 Page 13

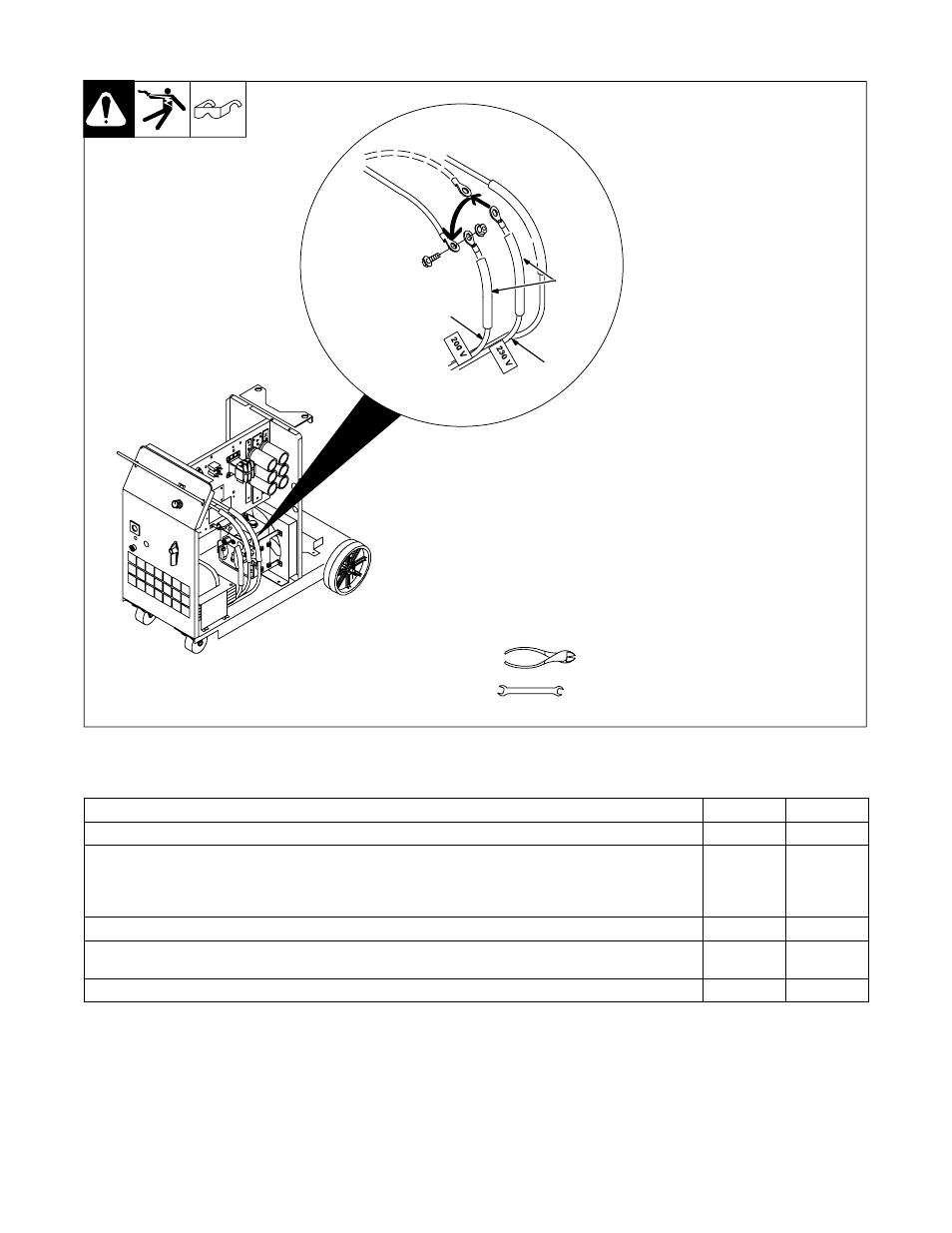

2-8.

Changing Input Voltage From 230 Volts To 200 Volts

Ref. 801 878-B

Cut cable ties as necessary.

1

230 Volt Lead

2

Tubing

Locate lead marked 230 VAC.

Slide tubing down and disconnect

lead splice.

Fold tubing over 230 volt lead stub

and secure.

3

200 Volt Lead

Locate lead marked 200 VAC.

Slide tubing down, and connect 200

volt lead stub to top half of the for-

mer 230 volt lead, and secure with

existing hardware.

Slide tubing over connection and

secure.

Tools Needed:

1

2

3

5/16, 3/8 in

2-9.

Electrical Service Guide

Input Voltage

200

230

Input Amperes At Rated Output

30

26

Max Recommended Standard Fuse Rating In Amperes

1

Time-Delay

2

35

30

Normal Operating 3

45

40

Min Input Conductor Size In AWG/Kcmil

10

10

Max Recommended Input Conductor Length In Feet (Meters)

97

(29)

128

(39)

Min Grounding Conductor Size In AWG/Kcmil

10

10

Reference: 1999 National Electrical Code (NEC)

1 Consult factory for circuit breaker applications.

2 “Time-Delay” fuses are UL class “RK5” .

3 “Normal Operating” (general purpose – no intentional delay) fuses are UL class “K5” (up to and including 60 amp), and UL class “H” ( 65 amp and

above).