General safety precautions – Husqvarna 445e TrioBrake User Manual

Page 15

GENERAL SAFETY PRECAUTIONS

English

–

15

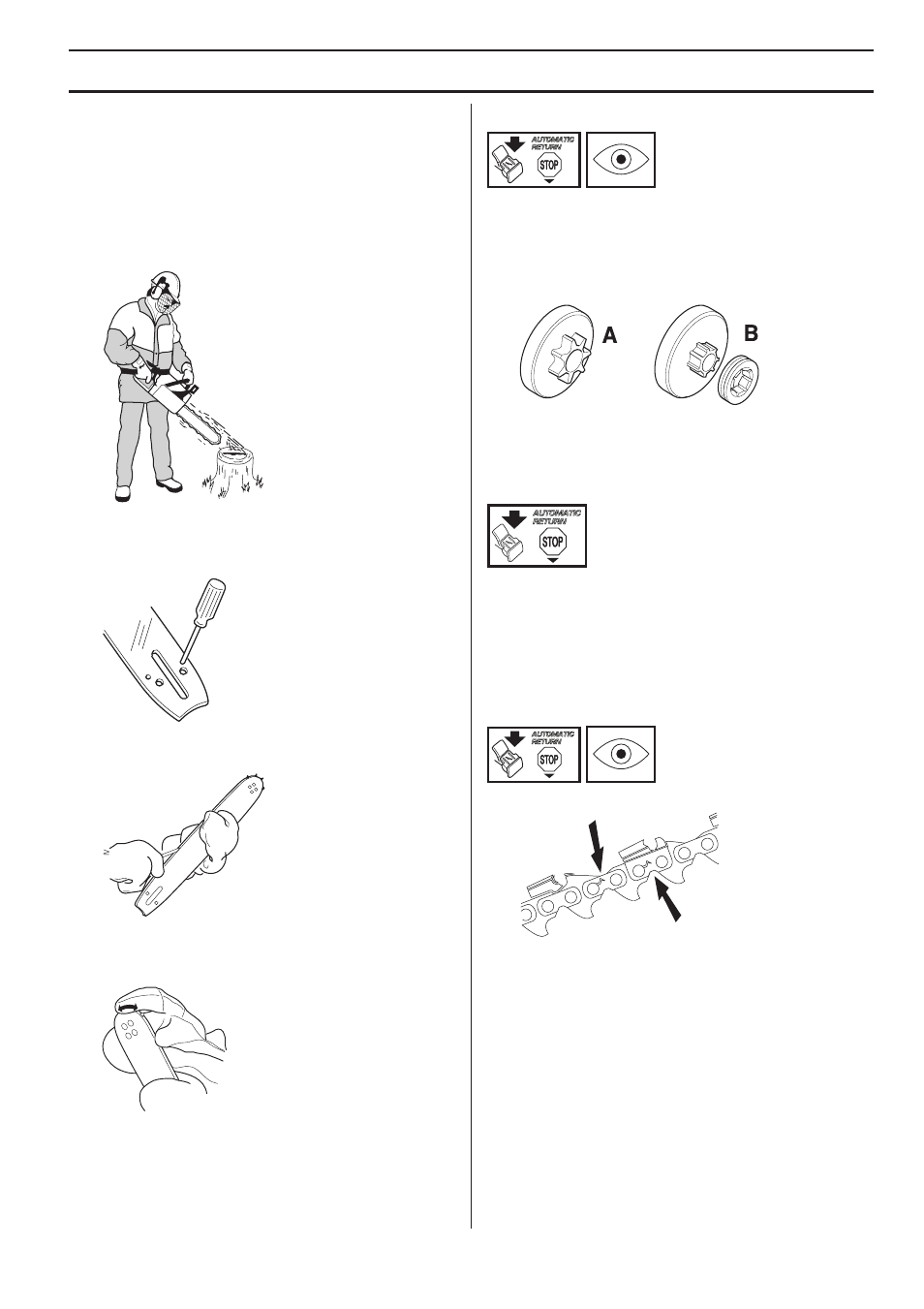

Checking chain lubrication

•

Check the chain lubrication each time you refuel. See

instructions under the heading Lubricating the bar tip

sprocket.

Aim the tip of the bar at a light coloured surface about

20 cm (8 inches) away. After 1 minute running at 3/4

throttle you should see a distinct line of oil on the light

surface.

If the chain lubrication is not working:

•

Check that the oil channel in the bar is not obstructed.

Clean if necessary.

•

Check that the groove in the edge of the bar is clean.

Clean if necessary.

•

Check that the bar tip sprocket turns freely and that

the lubricating hole in the tip sprocket is not blocked.

Clean and lubricate if necessary.

If the chain lubrication system is still not working after

carrying out the above checks and associated measures

you should contact your servicing dealer.

Chain drive sprocket

The clutch drum is fitted with one of the following drive

sprockets:

A Spur sprocket (the chain sprocket is welded on the

drum)

B Rim sprocket (replaceable)

Regularly check the degree of wear on the drive sprocket.

Replace if wear is excessive. Replace the drive sprocket

whenever you replace the chain.

Needle bearing lubrication

Both versions of sprockets have a needle bearing on the

drive shaft, which has to be greased regularly (once a

week). CAUTION! Use only high quality bearing grease or

engine oil.

See instructions under the heading Maintenance, Needle

bearing lubrication.

Checking wear on cutting equipment

Check the chain daily for:

•

Visible cracks in rivets and links.

•

Whether the chain is stiff.

•

Whether rivets and links are badly worn.

Replace the saw chain if it exhibits any of the points

above.

We recommend you compare the existing chain with a

new chain to decide how badly the existing chain is worn.

When the length of the cutting teeth has worn down to

only 0.16 inch (4 mm) the chain must be replaced.