Troubleshooting – Harbor Freight Tools 99640 User Manual

Page 13

SKU 99640

For technical questions, please call 1-800-444-3353.

Page 13

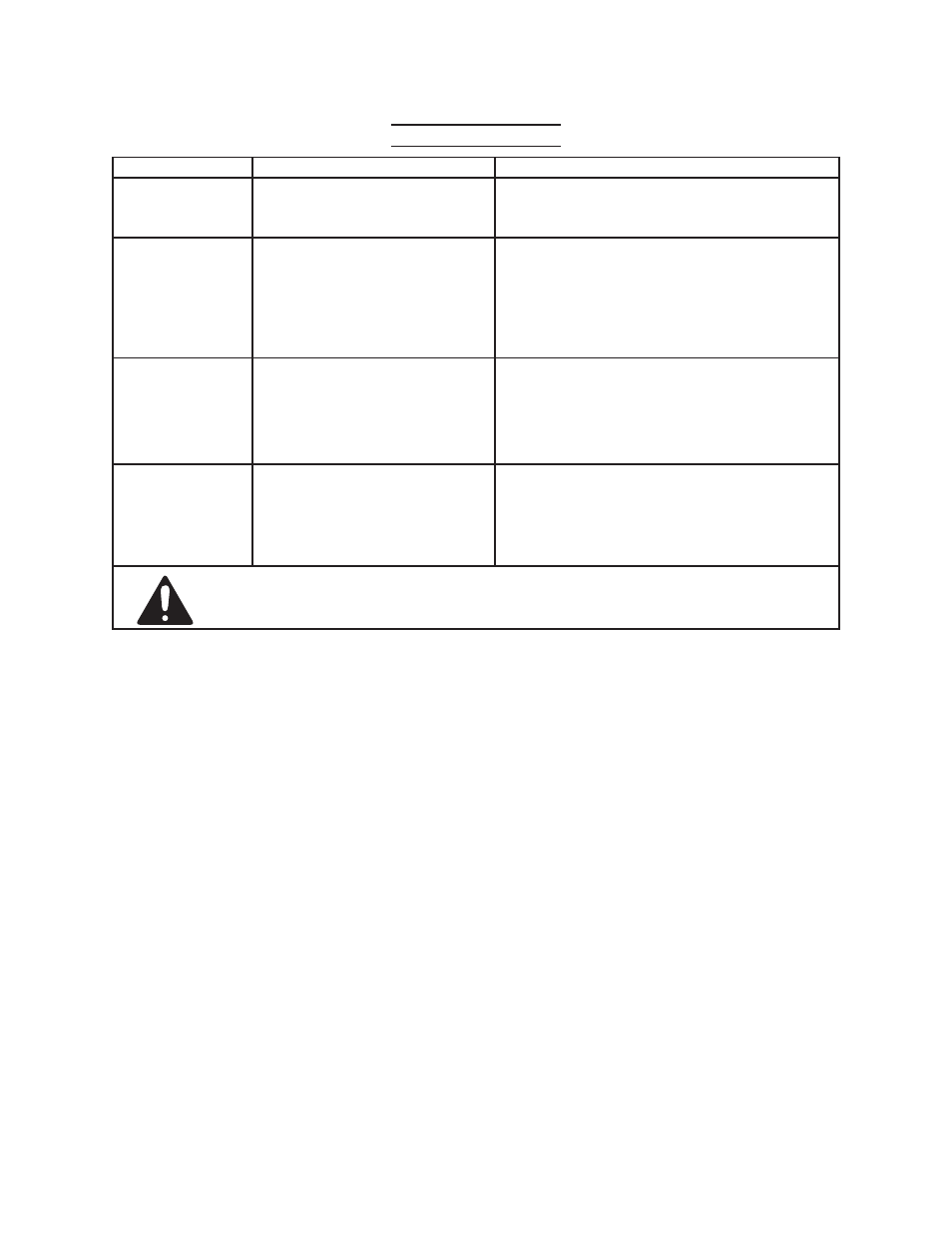

Troubleshooting

Problem

Possible Causes

Likely Solutions

Air leaking in Head

Cap (5).

1. Loose Bolt (3).

2. Lock Ring (11) is cracked or

worn.

1. Tighten and recheck.

2. Replace Lock Ring.

Lack of power.

Slow to cycle.

Low power when

shooting and

returning.

1. Tool is too dry.

2. Air pressure too low.

3. Exhaust blocked.

1. Add about 3 drops of pneumatic tool oil into

the Air Plug (82).

2. Check to make sure regulator on air

compressor is set between 70 PSI and 120

PSI.

3. Clean exhaust channel.

Not shooting

fasteners or

only intermittent

feeding.

1. Damaged Pusher Spring (51).

2. Wrong size of fasteners.

3. Fixed Magazine (52) or

Plate (45) is dirty.

1. Replace Spring.

2. Use 1/2” Crown Flooring Staples or 1-1/2” - 2”

“L” or “T” Type Flooring Cleats.

3. Clean Fixed Magazine and Plate.

Fastener is

jammed in tool.

1. Driver channel is worn.

2. Piston (25) is broken or worn.

3. Bent fasteners.

1. Replace Plate (45).

2. Replace Piston.

3. Remove bent fasteners. Replace with 1/2”

Crown Flooring Staples or 1-1/2” - 2” “L” or

“T” Type Flooring Cleats.

Follow all safety precautions whenever diagnosing or servicing the

tool. Disconnect air supply before service.