8. weld cable sizes, 9. connecting to weld output terminals – Hobart Welding Products BETASTICK 500 User Manual

Page 20

OM-201 444 Page 16

3-8.

Weld Cable Sizes

Total Cable (Copper) Length In Weld Circuit Not Exceeding

100 ft (30 m) Or Less

150 ft

(45 m)

200 ft

(60 m)

250 ft

(70 m)

300 ft

(90 m)

350 ft

(105 m)

400 ft

(120 m)

Welding

Amperes

10 To 60%

Duty Cycle

60 Thru 100%

Duty Cycle

10 Thru 100% Duty Cycle

100

4

4

4

3

2

1

1/0

1/0

150

3

3

2

1

1/0

2/0

3/0

3/0

200

3

2

1

1/0

2/0

3/0

4/0

4/0

250

2

1

1/0

2/0

3/0

4/0

2-2/0

2-2/0

300

1

1/0

2/0

3/0

4/0

2-2/0

2-3/0

2-3/0

350

1/0

2/0

3/0

4/0

2-2/0

2-3/0

2-3/0

2-4/0

400

1/0

2/0

3/0

4/0

2-2/0

2-3/0

2-4/0

2-4/0

500

2/0

3/0

4/0

2-2/0

2-3/0

2-4/0

3-3/0

3-3/0

600

3/0

4/0

2-2/0

2-3/0

2-4/0

3-3/0

3-4/0

3-4/0

*Weld cable size (AWG) is based on either a 4 volts or less drop or a current density of at least 300 circular mils per ampere. Contact your distributor for

the mm

2

equivalent weld cable sizes.

S-0007-E

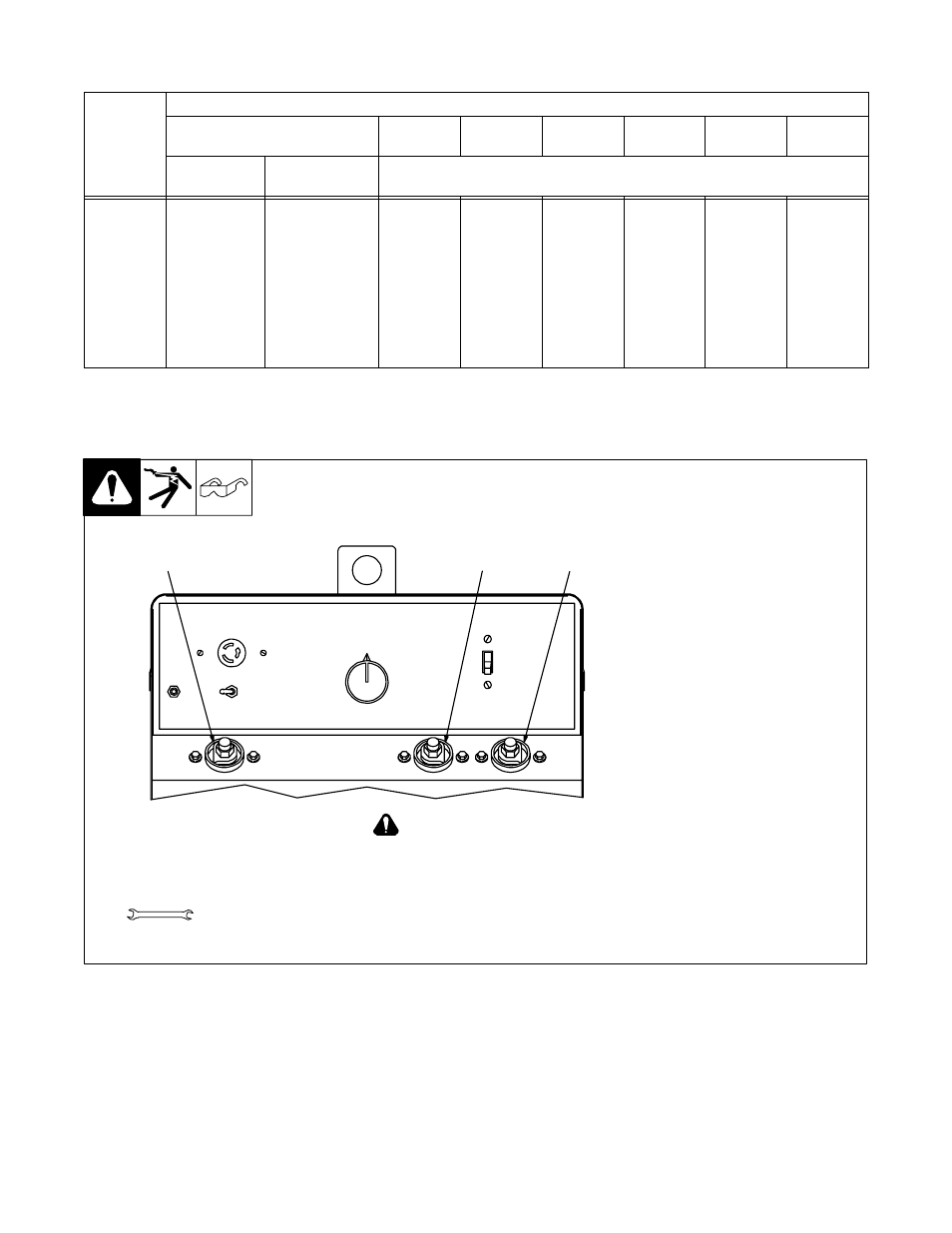

3-9.

Connecting To Weld Output Terminals

Ref. ST-800 040

Tools Needed:

Use ONLY one negative weld

output terminal at a time.

1

2

3

3/4 in

1

Positive (+) Weld Output

Terminal

2

A Negative (–) Weld Output

Terminal (Low Range)

3

B Negative (–) Weld Output

Terminal (High Range)

For DC Electrode Positive (DCEP),

connect work cable to negative (–)

terminal that supplies desired am-

perage range. Connect electrode

holder cable to positive (+) terminal.

For DC Electrode Negative

(DCEN), reverse cable connec-

tions.