2 remote radiator, 3 remote radiator/heat exchanger system, 4 heat exchanger cooling – HP Generating Set User Manual

Page 15

12

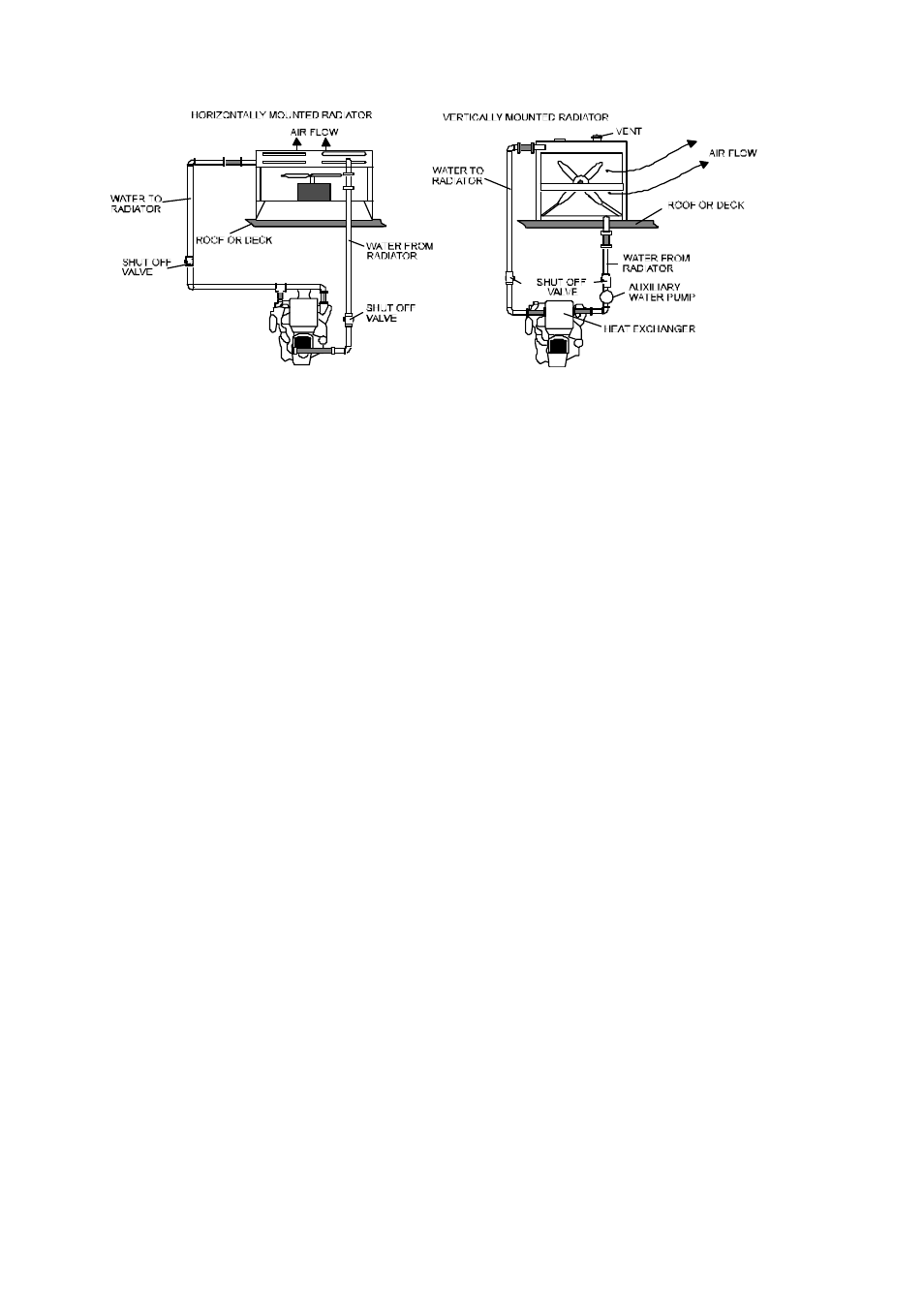

FIG 9.2

REMOTE RADIATOR CONNECTED DIRECTLY

FIG 9.3

REMOTE RADIATOR ISOLATED FROM

TO ENGINE COOLING SYSTEM

ENGINE COOLING SYSTEM BY HEAT

EXCHANGER

9.2 Remote Radiator

A remote radiator with electric motor-driven can be

installed in any convenient location away from the

generating set. See figure 9.2. A well-designed

remote radiator has many useful features and

advantages that provide greater flexibility of

generating set installations in buildings.

More efficient venturi shroud and fan provide a

substantial reduction in horsepower required for

engine cooling. The fan may be driven by a

thermostatically controlled motor, which will only

draw power from the generating set when required

to cool the engine. A remote radiator can be

located outdoors where there is less air flow

restriction and air is usually cooler than engine

room air, resulting in higher efficiency and smaller

size radiator; and fan noise is removed from the

building.

Remote radiators must be connected to the engine

cooling system by coolant piping, including flexible

sections between engine and piping.

9.3 Remote Radiator/Heat Exchanger

System

Another type of remote radiator system employs a

heat exchanger at the engine . See figure 9.3 and 9.4.

In this application, the heat exchanger functions as

an intermediate heat exchanger to isolate the engine

coolant system from the high static head of the

remote radiator coolant. The engine pump

circulates engine coolant through the engine and

the element of the heat exchanger.

A separate pump circulates radiator coolant

between the remote radiator and the heat exchanger

tank.

Heat exchangers also are used for cooling the

engine without a radiator, as described in the

following section.

9.4 Heat Exchanger Cooling

A heat exchanger may be used where there is a

continuously available supply of clean, cool raw

water. Areas where excessive foreign material in the

air might cause constant radiator clogging - such as

in saw mill installations - may be logical sites for

heat exchanger cooling. A heat exchanger cools the

engine by transferring engine coolant heat through

passages in the elements to cool raw water. Engine

coolant and raw cooling water flows are separated

completely in closed systems, each with its own

pump, and never intermix.

A heat exchanger totally replaces the radiator and

fan. See figure 9.5. It usually is furnished as part of

the generating set assembly, mounted on the

engine, although it can be located remotely. Since

the engine does not have to drive a radiator fan,

there is more reserve power available.

The raw water side of the heat exchanger requires a

dependable and economical supply of cool water.

Soft water is desired to keep the heat exchanger in

good operating condition. For standby service, a

well, lake or cooling tower is preferred over city

water since the latter may fail at the same time that

normal electric power fails, making the generator

useless.