HP Generating Set User Manual

Page 11

8

Excessive restriction in the exhaust system can be

avoided by proper design and construction. To

make sure you will avoid problems related to

excessive restriction, ask The FG Wilson distributor

to review your design.

The effect of pipe diameter, length and the

restriction of any bends in the system can be

calculated to make sure your exhaust system is

adequate without excessive back pressure. The

longer the pipe, and the more bends it contains, the

larger the diameter required to avoid excessive flow

restriction and back pressure. The back pressure

should be calculated during the installation stage to

make certain it will be within the recommended limits

for the engine.

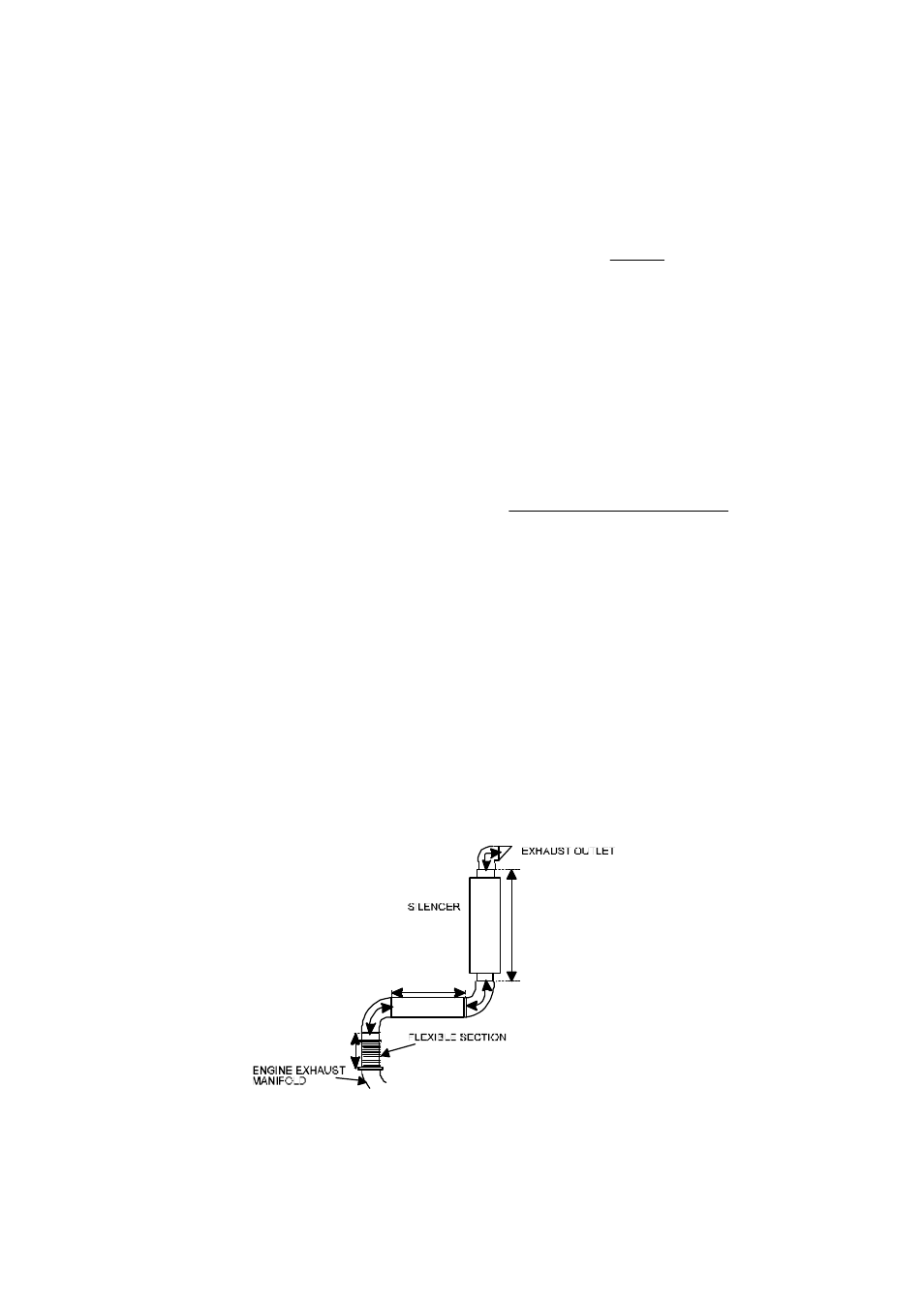

Measure the exhaust pipe length from your

installation layout. See figure 6.4. Take exhaust

flow data and back pressure limits from the

generating set engine specification sheet. Allowing

for restrictions of the exhaust silencer and any

elbows in the pipe, calculate the minimum pipe

diameter so that the total system restriction will not

exceed the recommended exhaust back pressure

limit. Allowance should be made for deterioration

and scale accumulation that may increase restriction

over a period of time.

Elbow restriction is most conveniently handled by

calculating an equivalent length of straight pipe for

each elbow and adding it to the total length of pipe.

For elbows and flexible sections, the equivalent

length of straight pipe is calculated as follows:

45

°

Elbow:

Length (ft) = 0.75 x Diameter (inches)

90

°

Elbow:

Length (ft) = 1.33 x Diameter (inches)

Flexible Sections:

Length (ft): 0.167 x Diameter (inches)

The following formula is used to calculate the back

pressure of an exhaust system:

P =

CLRQ

2

D

5

where:

P = back pressure in inches of mercury

C

= .00059 for engine combustion airflow of 100 to 400 cfm

= .00056 for engine combustion airflow of 400 to 700 cfm

= .00049 for engine combustion airflow of 700 to 2000 cfm

= .00044 for engine combustion airflow of 2000 to

5400 cfm

L

= length of exhaust pipe in feet

R

= exhaust density in pounds per cubic foot

R =

41.1

Exhaust temperature

o

F *

460

o

F

+

Q = exhaust gas flow in cubic feet per minute*

D = inside diameter of exhaust pipe in inches

* Available from engine specification sheet

These formulae assume that the exhaust pipe is

clean commercial steel or wrought iron. The back

pressure is dependent on the surface finish of the

piping and an increase in the pipe roughness will

increase the back pressure. The constant 41.1 is

based on the weight of combustion air and fuel

burned at rated load and SAE conditions. See

engine specification sheet for exhaust gas

temperature and air flow. Conversion tables to other

units are provided in Section 12.

FIG 6.4 MEASURING EXHAUST PIPE LENGTH TO DETERMINE EXHAUST BACK PRESSURE