Battery setup instructions – Harbor Freight Tools Gas Powered Two-Stage Air Compressor 67853 User Manual

Page 30

Page 7

For Engine technical questions, please call 1-800-520-0882.

Horizontal Engines

Set Up

Model 68120: The emission control system for this

engine is warranted for standards set by the U.S.

Environmental Protection Agency. For warranty

information, refer to the last pages of this manual.

Models 68306, 68121, and 68136: The emission

control system for this Generator’s Engine is warranted

for standards set by the U.S. Environmental Protection

Agency and by the California Air Resources Board

(also known as CARB). For warranty information,

refer to the last pages of this manual.

Read the ENTIRE IMPORTANT SAFETY

INFORMATION section at the beginning

of this manual including all text

under subheadings therein before

set up or use of this product.

TO PREVENT SERIOUS INJURY:

Operate only with proper spark arrestor installed.

Operation of this equipment may create sparks that

can start fires around dry vegetation.

A spark arrestor may be required.

The operator should contact local fire agencies for laws

or regulations relating to fire prevention requirements.

At high altitudes, the engine’s carburetor, governor (if so

equipped), and any other parts that control the fuel-air

ratio will need to be adjusted by a qualified mechanic to

allow efficient high-altitude use and to prevent damage to

the engine and any other devices used with this product.

WARNING! DO NOT INSTALL THIS

ENGINE ON A VEHICLE.

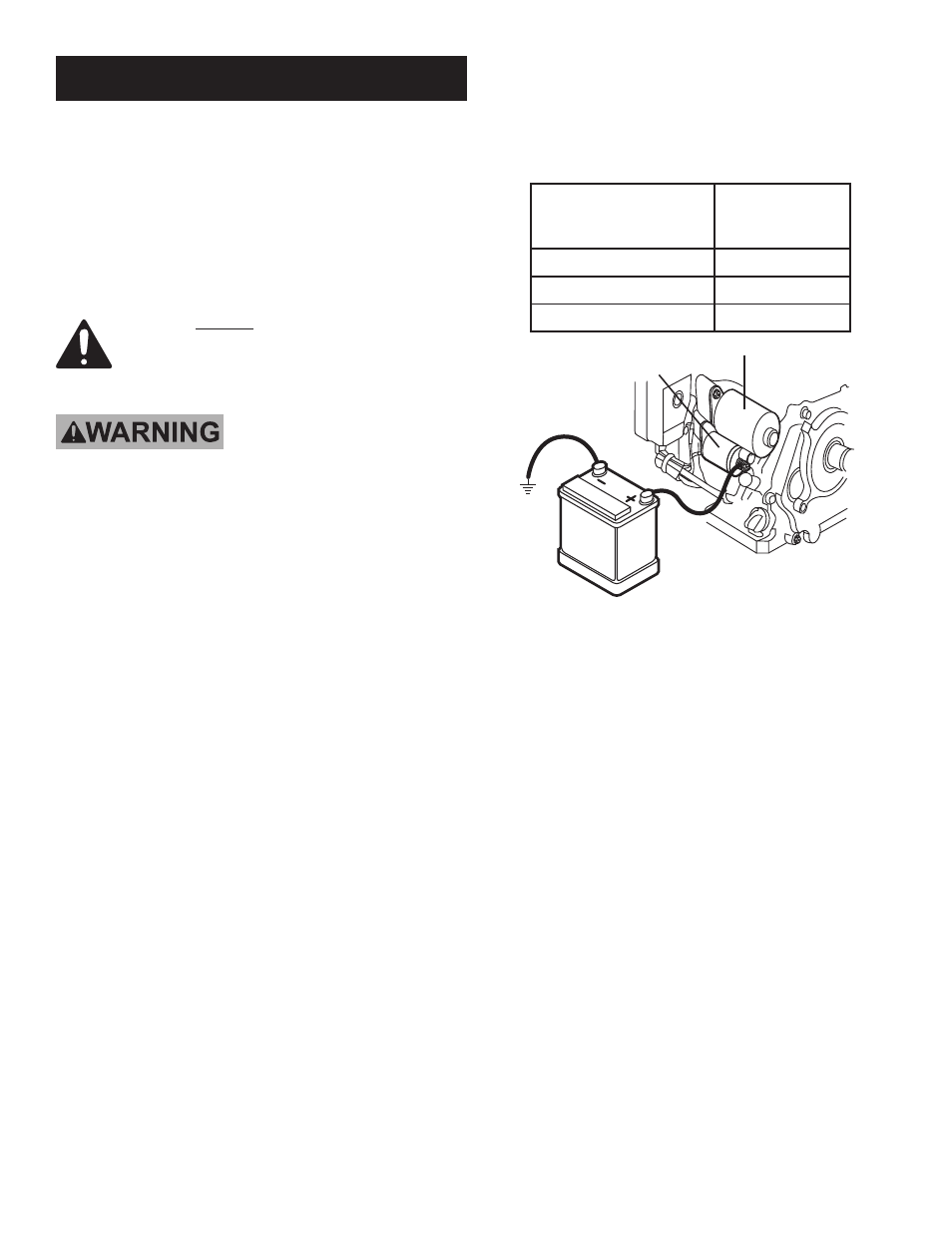

Battery Setup Instructions

1. Place a fully charged, lead-acid 12 V, 36+ Ah battery

(not included) in a stable, flat location near the engine.

2. Only use cables sized to match their length

according to the following chart:

Cable Gauge

(lower gauge numbers

mean thicker cables)

Maximum

Cable Length

6

5′

4

7′

2

12′

3.

Starting Relay

Motor Starter Assembly

Attach the positive cable from the positive

battery terminal to the Positive Terminal on the

starter, shown above. Connect cable securely

to prevent disconnection and short circuits.

4. Attach the negative cable to the

negative battery terminal.

5. Connect the negative cable securely to

one of the engine mounting bolts.