Troubleshooting – Harbor Freight Tools 66399 User Manual

Page 9

Page 9

For technical questions, please call 1-800-444-3353.

SKU 66399

and liquid soap (no harsh powder soap),

rinse thoroughly, and let dry

4. Insert back into the filter holder. Align

the three indexing ribs on filter housing

with the three recessed grooves in the fil-

ter cover and push the cover, snapping it

onto the housing. Thread the assembly

back into the front cover, being careful

not to cross thread it.

5. Lubricate the Shaft (30) and Piston Ring

(31) after using 20 times.

a. Remove four Screws (4) holding the

Front Cover (5) in place and slide the

Front Cover off. (See Assembly Dia-

gram.)

b. Put a drop or two of machine oil on the

Shaft (30) and Piston Ring (31). Note:

Turn the Compressor upside down to

allow the oil to penetrate onto the piston

rings.

c. Slide the Front Cover back on and se-

cure in place with the four screws.

6. If the Fuse (26) needs to be replaced,

snap off Fuse cover and then remove

and replace Fuse.

7. Slide out Fuse holder, replace old Fuse

with new Fuse included in the inflator

nozzle bag, and slide Fuse holder back

into slot. Fasten back into place with

screws.

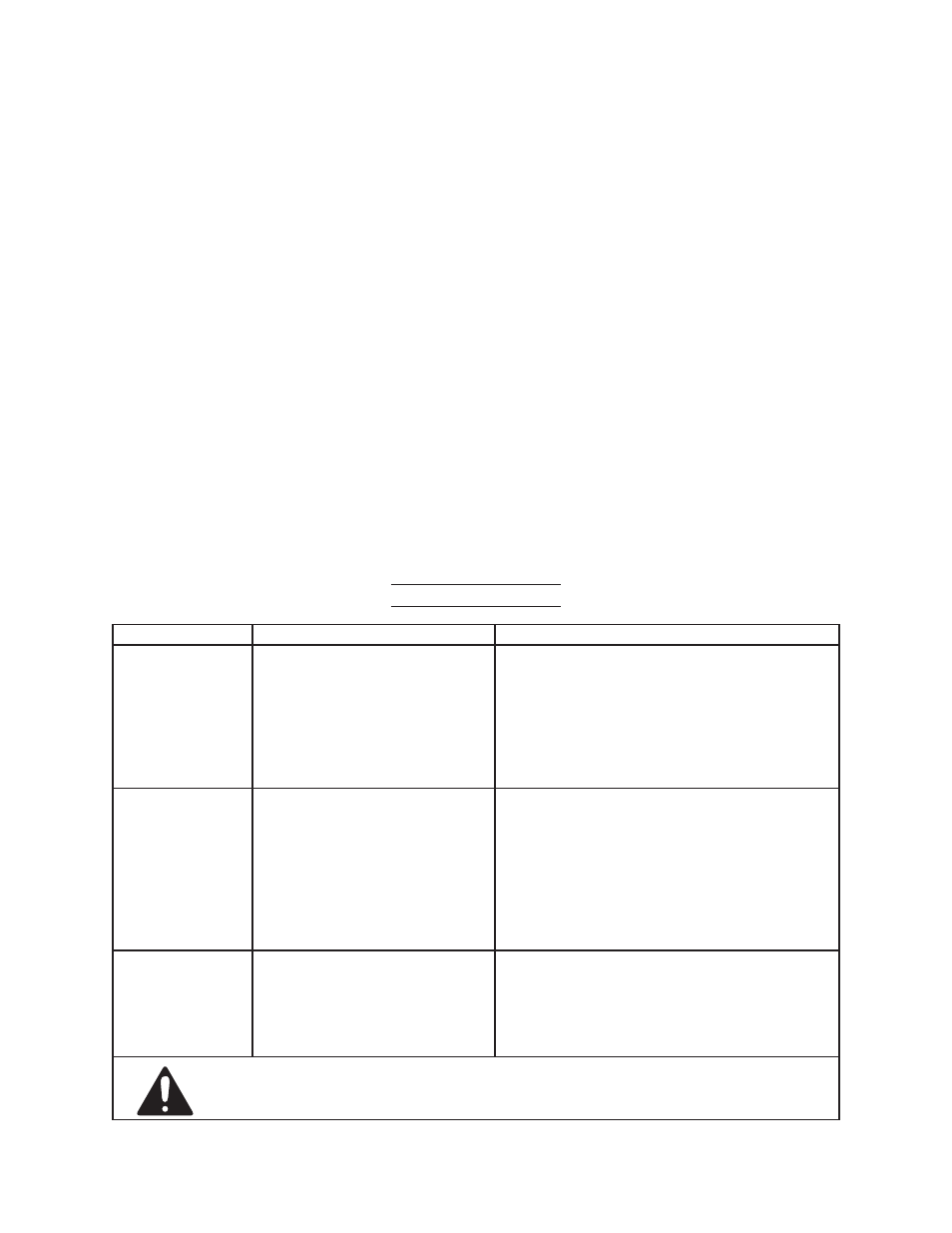

Troubleshooting

Problem

Possible Causes

Likely Solutions

Decreased output. 1. Not enough air pressure and/

or air flow.

2. Blocked air inlet Filter (3).

3. Air leaking from loose housing

or connections.

4. Mechanism contaminated.

1. Check for loose connections

.

2. Clean air inlet screen of buildup.

3. Make sure housing and connections are

properly assembled and tight.

4. Have qualified technician clean and where

possible, lubricate mechanism.

Severe air

leakage.

(Slight air leakage

is normal,

especially on older

tools.)

1. Cross-threaded housing

components.

2. Loose housing.

3. Damaged valve or housing.

4. Dirty, worn or damaged valve.

1. Check for incorrect alignment and uneven

gaps. If cross-threaded, disassemble and

replace damaged parts before use.

2. Tighten housing assembly. If housing cannot

be tightened properly, internal parts may be

misaligned.

3. Replace damaged components.

4. Clean or replace valve assembly.

No output

1. Poor clamp connection.

2. Power Switch in Off (O)

position.

3. Run-down battery.

4. Blown Fuse.

1. Clean clamps and reconnect properly.

2. Turn Power Switch to On (I) position.

3. Recharge battery.

4. Replace Fuse.

Follow all safety precautions whenever diagnosing or servicing the

tool. Disconnect from inflated item before service.

REV 10d