Save these instructions, Specifications, Initial tool set up/ assembly – Harbor Freight Tools 66399 User Manual

Page 5

Page 5

For technical questions, please call 1-800-444-3353.

SKU 66399

Vibration Precautions

This tool vibrates during use. Repeated

or long-term exposure to vibration may cause

temporary or permanent physical injury, par-

ticularly to the hands, arms and shoulders. To

reduce the risk of vibration-related injury:

Anyone using vibrating tools regularly

or for an extended period should first

be examined by a doctor and then have

regular medical check-ups to ensure

medical problems are not being caused

or worsened from use. Pregnant women

or people who have impaired blood cir-

culation to the hand, past hand injuries,

nervous system disorders, diabetes, or

Raynaud’s Disease should not use this

tool. If you feel any symptoms related

to vibration (such as tingling, numbness,

and white or blue fingers), seek medical

advice as soon as possible.

SAVE THESE

INSTRUCTIONS.

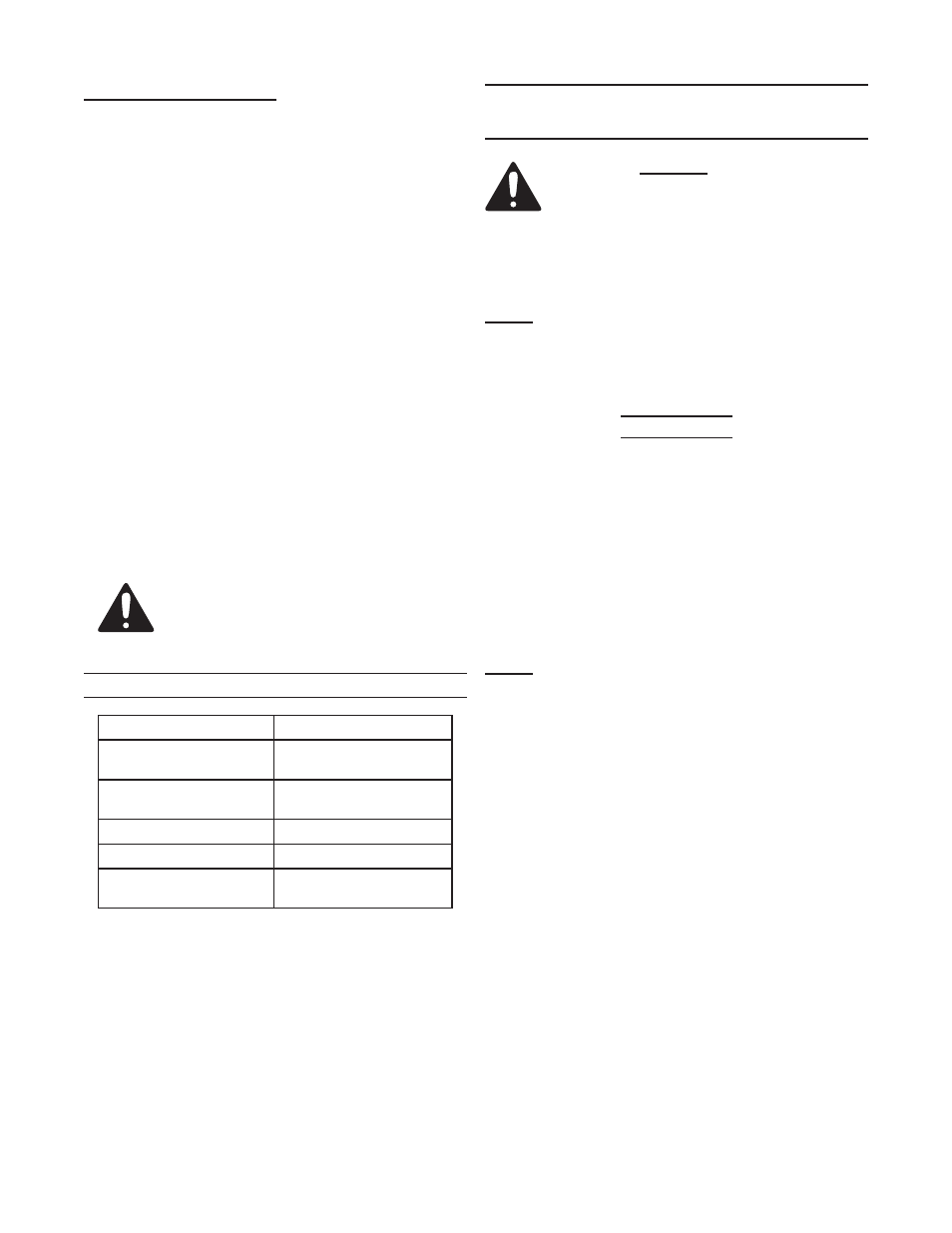

SPECIFICATIONS

Maximum Air Pressure 115 PSI

Speed

Fills Car Tire in Approx.

3 Minutes

Air Flow

1.3 SCFM @ 40 PSI

0.9 SCFM @ 90 PSI

Rated Air Pressure

0-115

Maximum Power

12VDC, 30 AMPS

Permanently Lubricated Do not add oil or any

other lubricant

INITIAL TOOL SET UP/

ASSEMBLY

Read the ENTIRE IMPORTANT

SAFETY INFORMATION

section at the beginning of this

manual including all text under

subheadings therein before set up

or use of this product.

Note: For additional information regarding the

parts listed in the following pages, refer

to the Assembly Diagram near the end of

this manual.

Unpacking

When unpacking, make sure that the

item is intact and undamaged. If any parts

are missing or broken, please call Harbor

Freight Tools at the number shown throughout

the manual as soon as possible.

• This air tool may be shipped with a

protective plug covering the air inlet.

Remove this plug before set up.

Note: Air flow, and therefore tool perfor-

mance, can be hindered by undersized

air supply components.

1. The air hose must be long enough to

reach the work area with enough extra

length to allow free movement while

working.

2. Turn the tool’s On/Off switch to the “OFF”

position; refer to Operation section for

description of controls.

3. Inspect the air connections for leaks.

Repair any leaks found.