Basic specifications, Unpacking, Set up instructions – Harbor Freight Tools GREYHOUND 56072 User Manual

Page 7: Assembly

SKU 56072

For technical questions, please call 1-800-444-3353.

Page 7

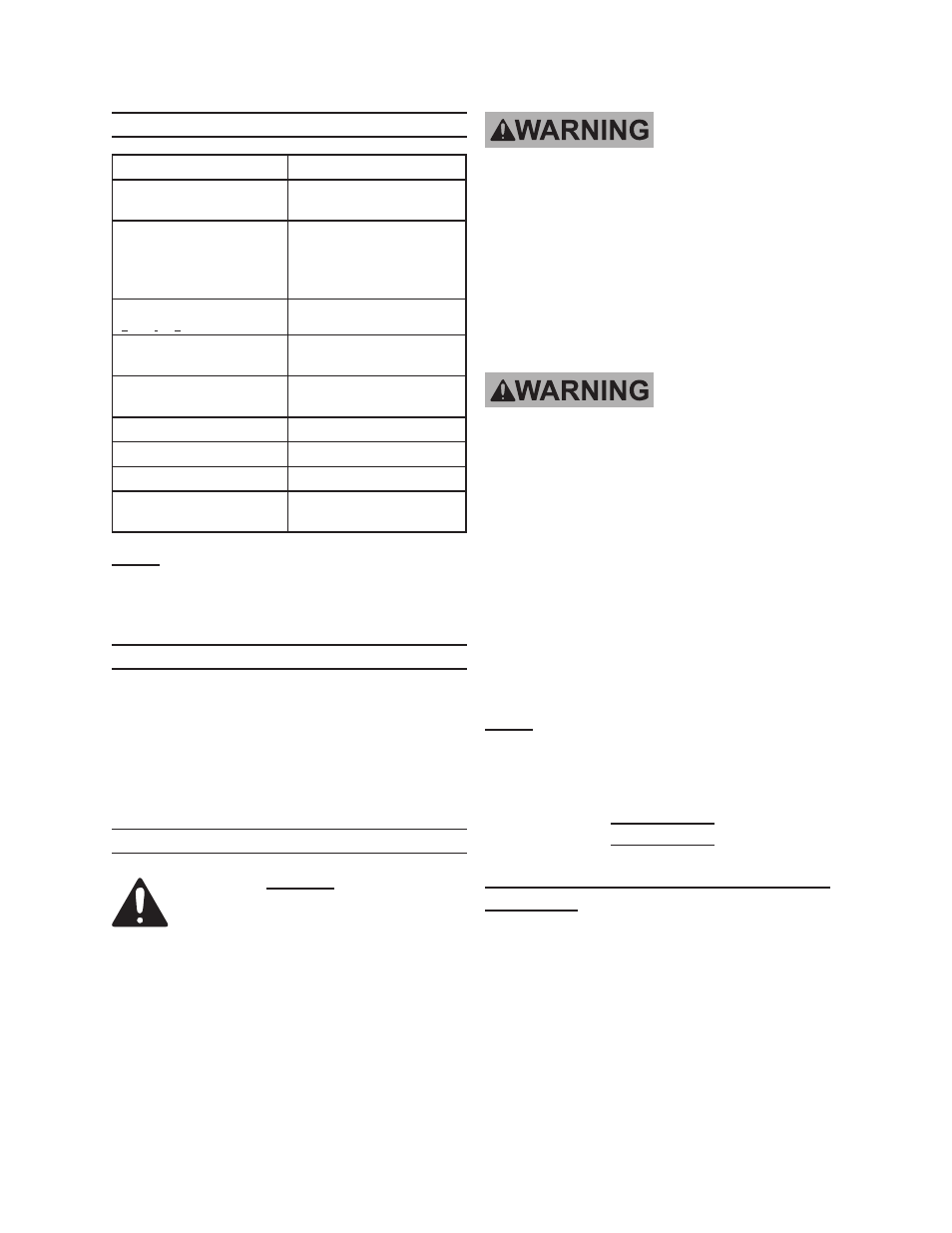

Basic speciFications

Hydraulic Jack Force

20 Tons

Hydraulic Fluid

Capacity

8 Gallons

Hydraulic Fluid

Anti-abrasion ISO

viscosity grade #46

Hydraulic Fluid. Change

every 100 hours of use.

Rotation

viewed from PTO

(power takeoff - the output shaft)

Counterclockwise

Maximum Log Size

25” Long x 12”

Diameter

Towing

For off-road use only

(not DOT approved)

Coupler Ball Required

2”

Wheel Size

8-4.80/4.00

Tire Air Pressure

60 PSI (cold)

Supplied Accessories

Hitch Coupler, Safety

Chain

note: Engine specifications are found in

the engine manual supplied with this

equipment.

unpacking

When unpacking, make sure that the

item is intact and undamaged. If any parts

are missing or broken, please call Harbor

Freight Tools at the number shown on the

cover of this manual as soon as possible.

set up instructions

read the entire iMportant

saFety inForMation

section at the beginning of this

manual including all text under

subheadings therein before set

up or use of this product.

to prevent

serious injury

FroM accidental

starting:

turn the power switch of the

equipment to its “oFF”

position, wait for the engine to

cool, and disconnect the

spark plug wire(s) before

assembling or making any

adjustments to the equipment.

to prevent

serious injury:

operate only with proper

spark arrestor installed.

operation of this equipment

may create sparks that

can start fires around dry

vegetation.

a spark arrestor may be

required.

the operator should contact

local fire agencies for laws

or regulations relating to fire

prevention requirements.

note: For additional information regarding

the parts listed in the following pages,

refer to the Assembly Diagram near

the end of this manual.

assembly

packing the Bearings / Hub and Wheel

assembly.

Whenever a hub is disassembled (if a

1.

hub on a new unit requires assembly

or a hub is disassembled for main-

tenance), the following procedure

MUST be followed.

Using a suitable solvent, clean the

2.

bearings and the rest of the parts of

the Hub assembly. The parts must