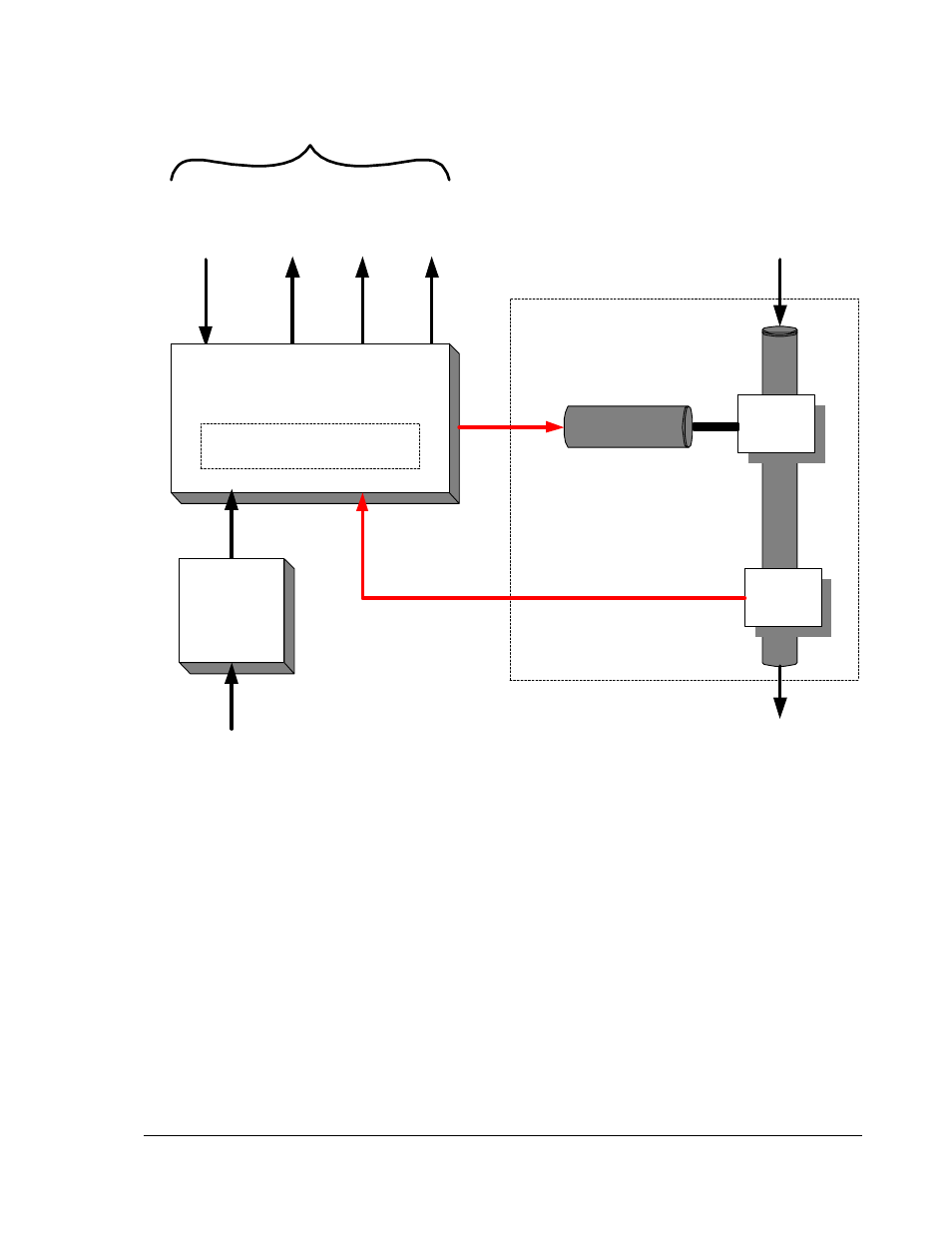

Figure 9, Figure 9: dripmaster functional diagram, Mechanical stage – Hoffman Media DRIPMASTER EDD-4C User Manual

Page 20: Control circuitry

20

Mechanical Stage

Optic

Drop

Detector

Needle

Valve

Oil Outlet to Shaft

Oil Inlet

from Reservoir

Lack of

Oil

O.K.

state

Drop

Pulses

Normal

/

Pre-lube

Modes

Line voltage

(115V or 230 V)

or 24V Feed

To SCADA Interface

Control Circuitry

Power

Supply

Servo

Motor

Preset Selectors & Display

Figure 9: Dripmaster functional diagram

A two-digit display is visible in the Dripmaster display window (see Figure 6 on page 13)—this is a

drip counter that freezes for six seconds for each one minute interval and indicates the number of

drips applied during the previous minute (Freeze mode).

During the freeze period, the servo motor is actuated to compensate for drip rate deviations.

A built-in fail-safe relay (O.K. relay) is energized when the drip rate exceeds fifteen drips per minute

in the Normal (pump on)l mode. External dry relay contacts permit direct control, such as pump

shut-off. Other dry contacts in the Dripmaster are available to transmit the drip rate, and for warning

of a total lack of oil condition.

The Dripmaster EDD-4C contains two drip rate settings, depending on the mode of operation:

• Normal (pump on) mode—the following values are selectable:

• 20, 25, 30, 35, or 40 drips/minute

• Pre-lube (pump off) mode—in this mode, the drip rate is automatically set to 2 dpm.