Pipe hot gas defrost – Heatcraft Refrigeration Products BN-LOPTB User Manual

Page 15

15

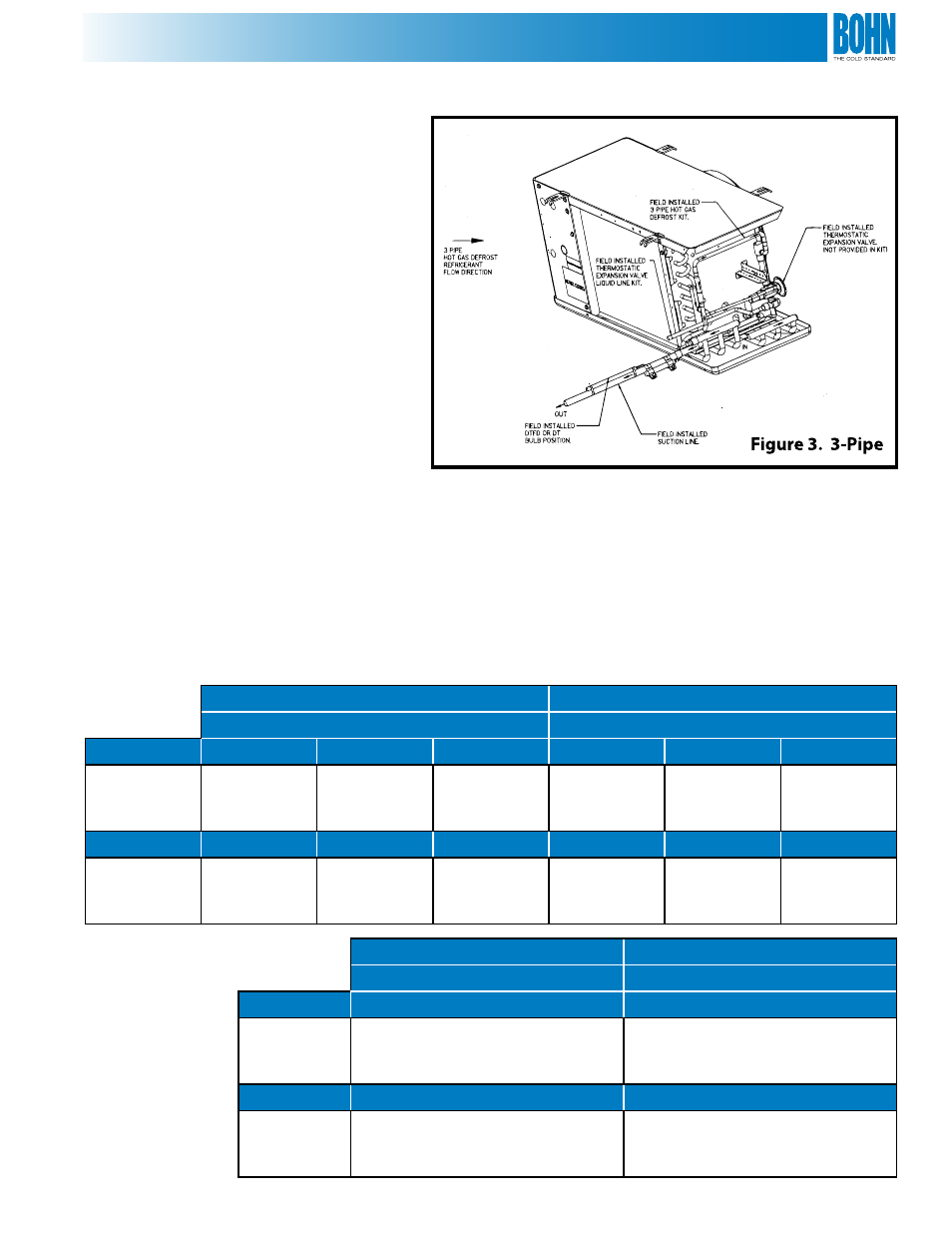

The hot gas defrost unit coolers conforms to

the standard 3-pipe hot gas system using a check

valve assembly, an electrical control to terminate

the defrost, and a hot gas solenoid valve. The

check valve assembly transports the hot gas

between the drain pan loop and the sideport

distributor of the coil. The check valve assembly kit

is available for shipped-loose or factory-installed

for an additional cost.

The electrical control option includes an

adjustable defrost termination and fan delay

control (DTFD) which is standard. An optional

(2) control electrical system is available with one

adjustable control for defrost termination (DT)

and one fixed control for the fan delay (FD) for

an additional cost. For both the DTFD and DT

adjustable controls, the remote bulb position is

with the bulb strapped to the suction line to insure

a complete defrost. The remote bulb is positioned

by the installer. The hot gas solenoid valve must be

ordered separately and will be shipped-loose. The thermostatic expansion valve could be ordered separately and shipped-

loose or the thermostatic expansion valve could be factory-installed with a liquid line for an additional cost.

The liquid line is designed for the body styles of the Sporlan SQE, SbF, EG and the Alco HFESC thermostatic expansion

valves. The thermostatic expansion valve needs to be selected by the sales engineer. In a typical 3-pipe, multiple evaporator

system, the compressor discharge defrosts the evaporator. The liquid/vapor mixture of refrigerant after defrost, however,

returns to the common suction line of the system. In order to provide sufficient re-evaporation of the liquid vapor mixture

and sufficient heat for defrost, no more than one-third of the system should be defrosted at one time. Some means of

control in the 3-pipe hot gas system should be supplied to regulate the large amount of liquid returning to the compressor,

refrigerant slugging can otherwise damage the compressor.

When using the hot

gas units with a hot

gas loop drain pan on

0°F applications and

below, an insulated

drain pan is required.

For hot gas models with the

hot gas loop drain pan only

Shipped-loose

Factory-installed

TXV Liquid Line

TXV Liquid Line

HGT 6 FPI

SQE/SBF

EG

HFESC

SQE/SBF

EG

HFESC

035-075

090-160

180-280

50169410

50169411

50169412

50169413

50169414

50169415

50169416

50169417

50169418

52733901

52733902

52733903

52733904

52733905

52733906

52733907

52733908

52733909

HGT FPI

041-080

102-204

235

50169410

50169411

50169412

50169413

50169414

50169415

50169416

50169417

50169418

52733901

52733902

52733903

52733904

52733905

52733906

52733907

52733908

52733909

Shipped-loose

Factory-installed

Drain Pan Loop Check Valve Kit Drain Pan Loop Check Valve Kit

HGT 6 FPI

035-075

090-160

180-280

50169504

50169505

50169506

52739601

52739602

52739603

HGT FPI

041-080

102-204

235

50169504

50169505

50169506

52739601

52739602

52739603

3-Pipe Hot Gas Defrost