Mower maintenance, Securing nuts & bolts, Lubrication – Hayter Mowers Hayter Sprint 41 616E User Manual

Page 12: Cutterblade removal, Cutterblade assembly, Cutterblade sharpening

12

13

Securing Nuts & Bolts

Regularly check that all securing nuts and bolts are tight.

Replace missing or damaged items immediately.

Lubrication

Lubricate the wheels, pivot points and linkages with

engine oil every 25 operating hours.

Apply a good quality medium grease to the inner control

cables at the point of entry and exit from their outer cas-

ing.

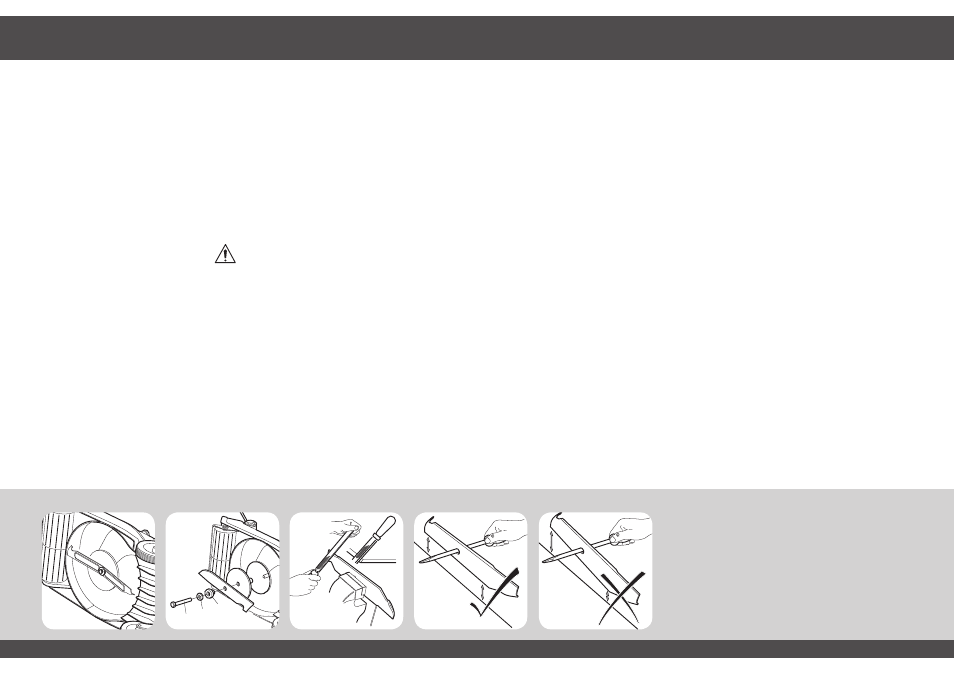

Cutterblade Removal

Drain the fuel by running the engine until the fuel tank

is empty and the engine stops. Remove the spark plug

lead and allow the engine to cool. Turn the mower on its

left hand side and ensure that the air cleaner side of the

engine is uppermost. (Refer fig.28)

Firmly grip the end of the cutterblade with a gloved hand

and remove the bolt, spring washer and distance piece

securing the cutterblade with a 9/16” A/F spanner. (Refer

fig.29)

To prevent accidents never work on the cutterblade

unless the spark plug lead has been removed. The

cutterblade has sharp edges. ALWAYS wear strong

gloves to protect your hands when working on the

cutterblade. DO NOT rotate tools towards the cutting

edges to avoid the risk of injury should the tool slip.

ALWAYS use genuine Hayter replacement parts.

The condition of the cutterblade and its mounting

arrangement should be checked regularly for signs of

wear or damage. Ensure that the cutterblade is not bent

or cracked.

A damaged cutterblade that is out of balance will vibrate

excessively and may break. DO NOT use an unbalanced

cutterblade.

Regularly check that the bolt securing the cutterblade is

tightened to the specified torque of 54Nm.

Replace the cutterblade every 2 years of sooner if

excessively worn or damaged.

To prevent injury it is wise to seek assistance when

turning the mower on its side.

Cutterblade Assembly

Assemble the cutterblade with the turned up edges facing

towards the engine. Secure the cutterblade using the bolt

(1), spring washer (2), distance piece (3) and tighten to a

torque of 54Nm. (Refer fig.29)

Cutterblade Sharpening

A slightly worn cutterblade may be re-sharpened. Both

blade edges must be sharpened equally to ensure balance.

Sharpen the cutterblade every 25 mowing hours or more

frequently if conditions require. Remove the cutterblade

from the mower and clean using a brush and water. In-

spect the cutterblade for signs of damage.

Sharpen both cutting edges with a flat file to restore per-

formance. (Refer fig.30)

Ensure that the cutterblade is balanced. Use a screw driv-

er with a round shaft to support the cutterblade through

its centre hole. Hold the cutterblade horizontal and then

release. A balanced cutterblade will remain horizontal.

(Refer fig.31)

If the cutterblade is not balanced the heavy end will

rotate downwards. Sharpen the heavy end until the

cutterblade is correctly balanced. (Refer fig.32)

MOWER MAINTENANCE

Fig. 28

Fig. 29

Fig. 30

1

2 3

30-45

Fig. 32

Fig. 31