Hobart Welding Products OM-494 User Manual

Page 26

OM-494 Page 22

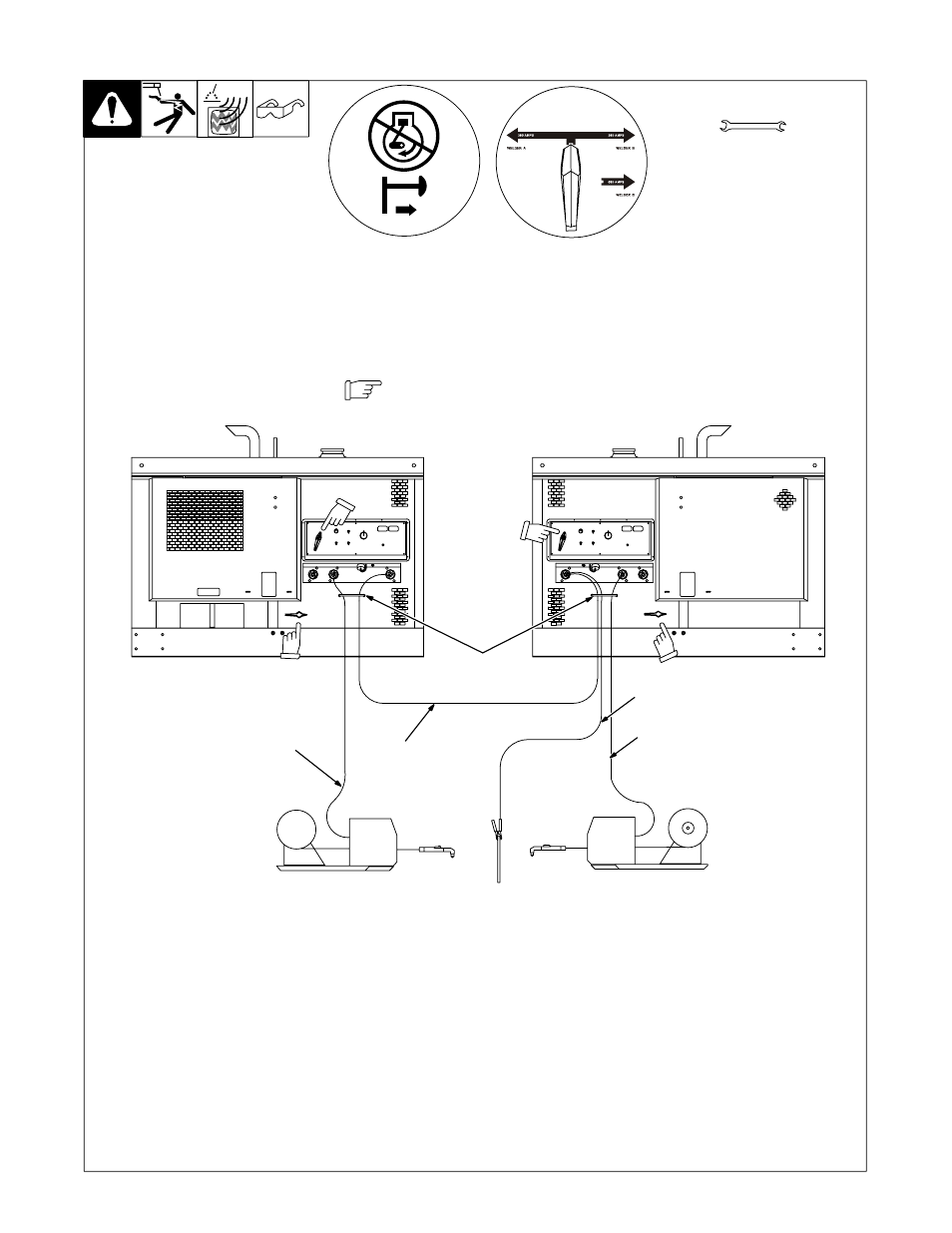

4-11. Making Dual Operator CV Weld Connections w/ Common Work Cable

Ref. 190 377 / 802 292-A

Y

Stop engine.

Y

Do not exceed machine duty cycle.

.

For common work connection, work

cable must be able to carry combined

weld output of both CC weld output ter-

minals (see Section 4-15 for proper

cable size).

.

Use Dual Operator mode for CC and

CV welding (see Section 5-1).

1

Strain Relief

Route cables through strain reliefs.

2

Wire Feeder Cables

3

Work Jumper Cable

4

Common Work Cable

For MIG and FCAW welding Direct Current

Electrode Positive (DCEP), connect com-

mon work cable and work jumper cable to

Welder B (right) Negative (–) terminal. Con-

nect other end of work jumper cable to

Welder A (left) Negative (–) terminal.

Connect wire feeder cables to CV termi-

nals.

For MIG and FCAW Direct Current Elec-

trode Negative (DCEN), connect common

work cable and work jumper cable to Weld-

er B (right) CV terminal. Connect other end

of work jumper cable to Welder A (left) CV

terminal.

Connect wire feeder cables to Negative (–)

terminals.

If unit has the Polarity switch option, con-

nect common work cable and work jumper

cable to Welder B (right) Work receptacle.

Connect other end of work jumper cable to

Welder A (left) Work receptacle.

Connect wire feeder cables to CV recep-

tacles.

.

Place optional Polarity switches in Re-

verse position when using CV weld re-

ceptacles. There is no CV weld output

when switch is in Straight position.

.

Be sure Process Selector and Polarity

switches are set correctly. See Section

5-3.

Tools Needed:

Welder A (Left) Side

3/4 in

Welder B (Right) Side

Y

INADEQUATE CABLE CONNECTIONS can cause serious damage to welding generator and create a hazardous condition.

When making weld connections with a common work cable, connect a weld cable of adequate size between the Negative (–) weld termi-

nals, and connect a single weld cable of adequate size from the Welder B (right) Negative (–) terminal to the workpiece.

When using these connections as a common work terminal, all connections must be of the same polarity.

For a common work cable connection, the work cable must be able to carry the combined weld output of both modules (see Section 4-15

for proper cable size).

1

2

2

3

4

Direct Current Electrode Positive

(DCEP) connections are shown.

Note position

of Process

Selector

switches.

Note position

of optional

Polarity

switch.

Note position of optional

Polarity switch.