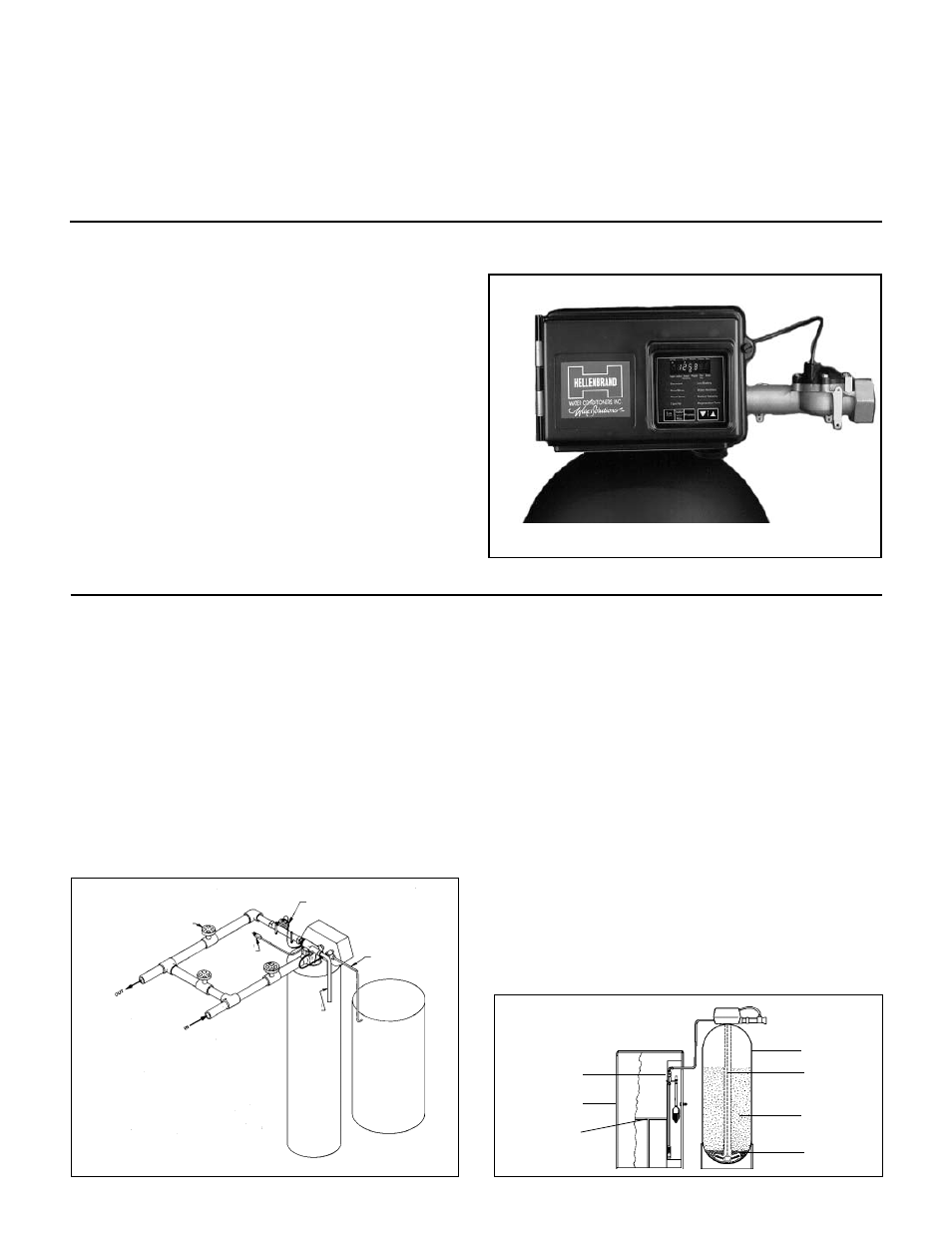

Econominder meter, Ts series – Hellenbrand TS Series User Manual

Page 3

Specifications

Pipe Size:

1"

1.5"

Flow Ranges (gpm):

.7 - 40

1.5 - 75

Accuracy:

+/- 5%

+/- 5%

Features:

Volume Display in Gallons

Hardness Display in Grains per Gallon

System Capacity Display in Kilograins

System Flow Rate Display in Gallons Per Minute

Totalizing Metering

Programmable Timed Auxiliary Output Relay

Fully Adjustable Regeneration Cycles

Program Lockout Protection

Adjustable Regeneration Times

Variable Reserve Capacity Based On Previous Water Usage History

Delayed or Immediate Regeneration

Calendar Day Override

System Diagnostic Displays

Microprocessor - Transformer supplied 115V Primary, 24V Secondary

ET Microprocessor Meter Controller

Regeneration Options

Manual control requires no electricity for operation. Opera-

tor must start and end the regeneration including backwash,

brine and rinse, and fast rinse times and manually return unit

to service. A float valve is used to regulate salt usage.

Time clock control with either a 7 or 12 day timer, allows

the operator to preset regeneration time and frequency as

needed. A built-in manual override is included for increased

water usage times.

Water meter demand control systems are recommended for

those applications where daily water usage varies throughout

the year. Meter demand systems are available with either

mechanical or microprocessor based systems. Both types

of metering systems are available with either delayed or im-

mediate regeneration.

Econominder Meter

Specifications

Pipe Size:

3/4"

1"

1-1/2"

Flow Ranges:

.15-20

.7-40

1.5-70

Accuracy:

± 5%

± 5%

± 5%

Meter Gallon Ranges:

A) 3/4"

Standard Range: 125 - 2,125 Gallons

Extended Range: 625 - 10,625 Gallons

B) 1"

Standard Range: 360 - 5,100 Gallons

Extended Range: 1,800 - 25,200 Gallons

C) 1-1/2"

Standard Range: 625 - 10,625 Gallons

Extended Range: 3,125 - 53,125 Gallons

A

. MINERAL TANK: NSF Approved, UL Listed, Fiberglass

Reinforced Pressure Vessel Manufactured to Operate at 150

psi and 120 F.

B. DISTRIBUTOR SYSTEM: Hub & Lateral or Bottom Stack

Distributor System for Maximum Service Flow and Minimal

Pressure Loss.

C. MINERAL: FDA Approved, High Capacity Ion Exchange.

Resin has uniform and stable beads assuring long life, high

salt efficiency, and maximum hardness removal.

D. UNDERBEDDING: Gravel Underbedding assures full

usage of mineral bed and allows for a smooth and constant

water flow for service and regeneration.

E. BRINE TANK: High Density Polyethylene Brine Tank

has exceptional environmental stress crack properties. It will

not crack or rust out. Dust-tight covers keep out unwanted

impurities.

F. SALT GRID SYSTEM: Hellenbrand’s High Salt Grid Sys-

tem allows for only a minimal of salt being wetted, helping to

eliminate problems from bridging salt.

G. SAFETY BRINE VALVE: An optional safety brine valve,

acts as a secondary shut-off in case of a failure with primary

shut-off.

TS Series

A

B

C

D

F

E

G

Typical Piping Installation

BRINE

TANK

RESIN

TANK

BRINE

LINE

DRAIN

LINE

POWER

CORD

OPTIONAL METER

MANUAL

SHUT-