Beacon controller, Beacon, General – Heatcraft Refrigeration Products BEACON 25001501 User Manual

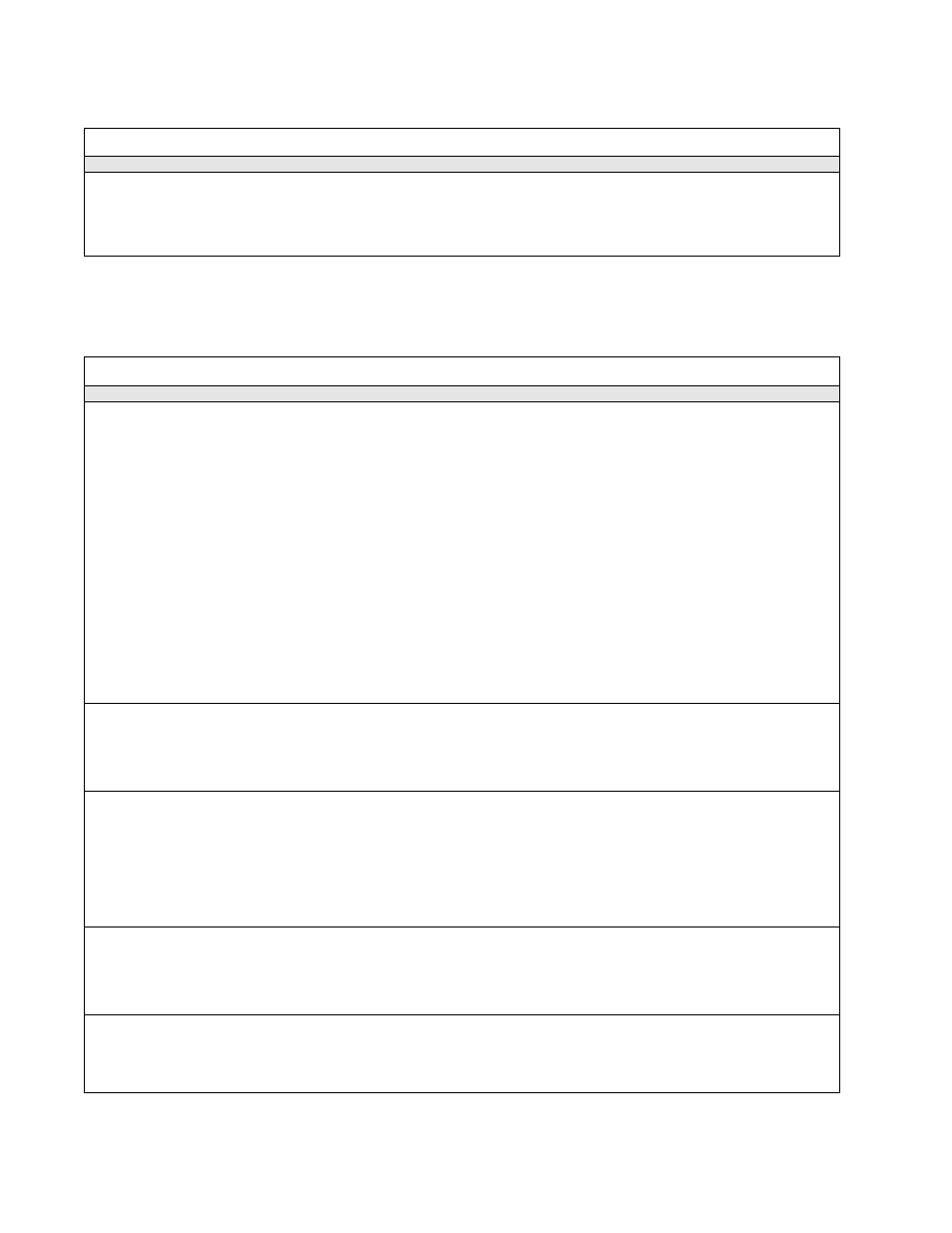

Page 20: Service diagnosis chart, Cont’d.)

BEACON CONTROLLER

20

PROBLEM

POSSIBLE CAUSE

POSSIBLE CORRECTIVE ACTION

Beacon Board Status

1. Supply voltage too high

1. Check 24 volt supply; if above 30 volt

Light Flashes Erratically

correct immediately.

2. Supply voltage too low

2. Change transformer primary to correct supply

3. Bad board

voltage tap. 208 or 240 volts.

SERVICE DIAGNOSIS CHART -

BEACON

(cont’d.)

PROBLEM

POSSIBLE CAUSE

POSSIBLE CORRECTIVE ACTION

Compressor will not run

1. Fused disconnect switch is open

1. Close switch

2. Blown Fuse

2. Check reason fuse is blown; replace fuse

after problem is corrected.

3. Compressor motor protector open

3. Motor protector is automatic reset; allow

time for compressor to cool down so that

protector will reset; check unit for reason

when compressor restarts.

4. Defective compressor contactor

4. Replace

or holding coil

5. Open room air sensor (air into coil)

5. Check room air sensor; if open, replace. After

reconnecting, wait 4 mins. for compressor to

restart.

6. Compressor discharge too hot

6. Lower evaporator superheat to lower

compressor suction gas temperature

7. Open low pressure, high pressure

7. Check control settings

or oil safety control

8. Motor problems

8. Check motor for open circuit, short circuit,

grounded windings or burn-out

9. Loose wiring

9. Check all wire terminals; tighten if necessary

Compressor noisy or

1. Flooding of liquid refrigerant into

1. Check expansion valve superheat setting

vibrating

into crankcase

on control board

2. Compressor hold-down nuts too

2. Loosen compressor hold-down nuts until

tight or too loose

compressor floats freely on mounting springs

3. Worn compressor/bad valves

3. Replace

High head pressure

1. Too much refrigerant

1. Remove excess refrigerant

2. Non-condensables in the system

2. Purge system of non-condensables

3. Dirty condenser coil

3. Clean condenser coil

4. Condenser fan not running

4. Check electrical circuit, including fuses

5. Discharge valve partially closed

5. Open valve

6. System running beyond condensing

temperatures due to heavy load

or out of equipment design paramaters

Low head pressure

1. Insufficient refrigerant

1. Check system for leaks; repair leaks &

add refrigerant

2. Damaged valves in compressor

2. Replace compressor

3. Winter operation w/o head

3. Check refrigerant charge

pressure valve

High suction pressure

1. Expansion valve over-feeding

1. Check expansion valve superheat setting

on control board

2. High box temp. pull-down

2. Wait for box temp. to drop

3. System undersized

3. Check load & design criteria

SERVICE DIAGNOSIS CHART -

GENERAL