HP FM Centrifugal Pump PCN=71576526 User Manual

Page 16

FM USER INSTRUCTIONS ENGLISH 71576526 - 03/07

Page 16 of 32

flowserve.com

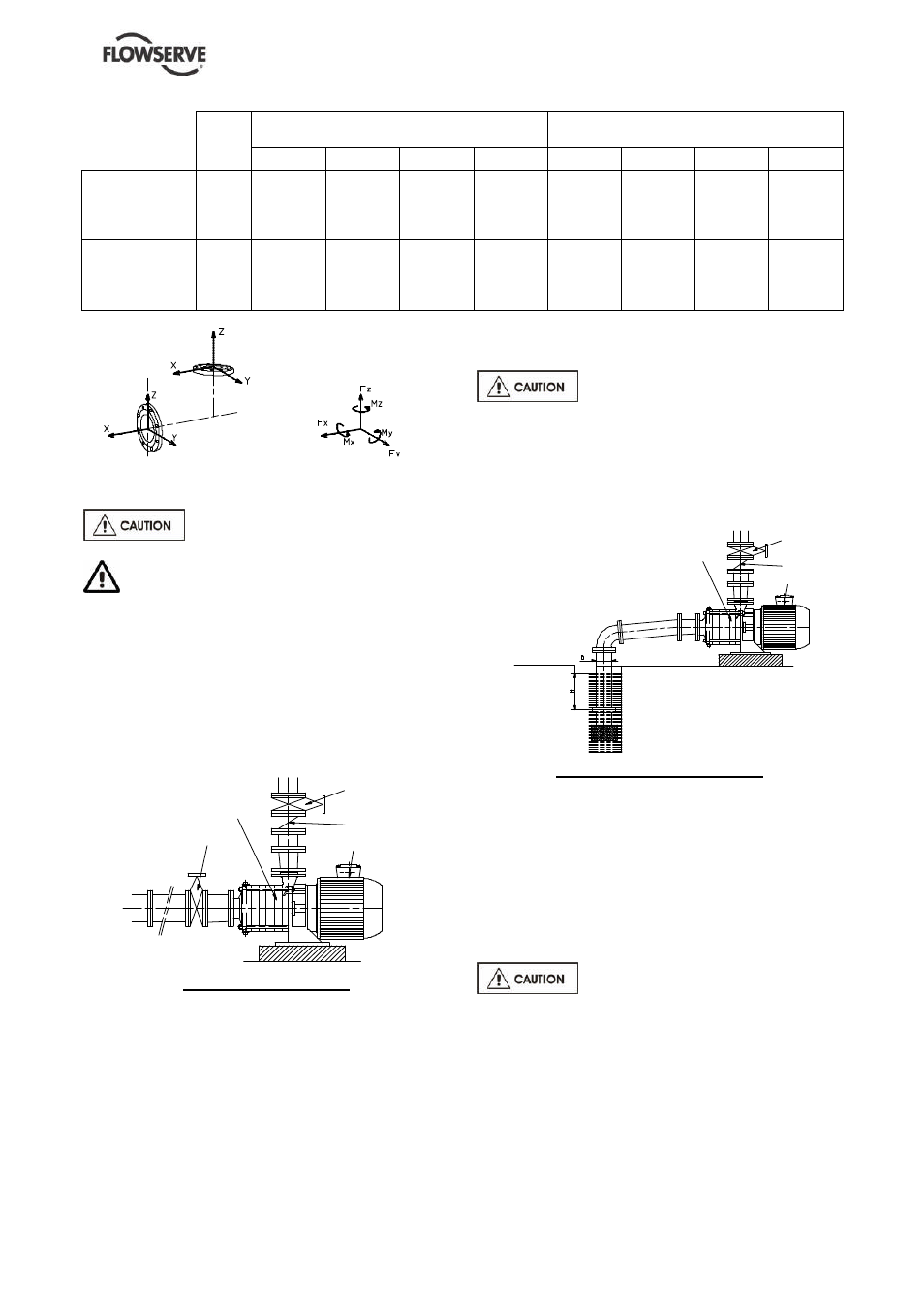

Forces

daN (lbf)

Moments

m.daN (lbf.ft)

DN

F

Y

F

Z

F

X

F

M

Y

M

Z

M

X

M

40

(1"1/2)

30

(67)

40

(90)

35

(79)

60

(135)

23

(170)

27

(199)

34

(251)

49

(361)

Vertical pipework

perpendicular to

the shaft

50

(2")

40

(90)

50

(112)

45

(101)

80

(180)

27

(199)

30

(221)

37

(273)

54

(398)

50

(2")

45

(101)

40

(90)

50

(112)

80

(180)

27

(199)

30

(221)

37

(273)

54

(398)

Axial pipework

parallel to the

axis

65

(2"1/2)

58

(130)

50

(112)

68

(153)

102

(229)

30

(221)

33

(243)

40

(295)

60

(443)

Forces and moments values are applied to the

whole flanges and not flange by flange.

Ensure piping and fittings are flushed

before use.

Ensure piping for hazardous liquids is

arranged to allow pump flushing before removal of

the pump

4.3.2 Suction piping

4.3.2.1 Design of a flooded suction line

The suction line must be as short and direct as

possible, never mount an elbow directly on the inlet

flange of the pump.

Valve

Non -return valve

Motor

FM

Continuous flow valve

Flooded suction pump

a) Avoid sharp elbows or sudden narrowing. Use

convergent

20° (total angle).

b)

Arrange the piping so that there are no air

pockets (no bulges).

c)

If high points cannot be avoided in suction line,

provide them with air relief cocks.

d)

If a strainer is necessary, its net area should be

three or four times the area of the suction pipe.

e) If an inlet valve is necessary, choose a model

with direct crossing.

Do not tighten flanges before the final

check (see § 4.3.4).

4.3.2.2 Design of a suction lift line

The inlet pipe must be as short and as direct as

possible, never place an elbow directly on the pump

inlet nozzle.

Valve

Non- return valve

Motor

FM

Sufficient

immersion: I

I

3 x D

Sump suction configuration

a) Avoid sharp elbows or sudden narrowing. Use

convergent

20° (total angle) with upright

generating.

b)

Arrange that the suction piping is inclined

upwards towards the pump ensuring that there

are no peaks.

c)

If a foot valve is necessary, do not oversize it

because it would generate pulsations (valve

beating).

Do not tighten flanges before the final

check (see § 4.3.4).

4.3.3 Discharge piping

4.3.3.1 Design of a discharge line

a) If discharge line is provided with a divergent, its

total angle will be between 7° and 12°.

b)

Install the discharge valve after the non-return

valve downstream.