Troubleshooting – Harbor Freight Tools Heavy Duty Air Paint Spray Gun 97855 User Manual

Page 14

SKU 97855

For technical questions, please call 1-800-444-3353.

Page 14

7.

Disposal: After cleaning your Spray

Gun, properly dispose of your clean-

ing solutions according to the solution

manufacturer’s direction and local

hazardous waste standards.

Note: These procedures are in addition to

the regular checks and maintenance

explained as part of the regular op-

eration of the air-operated tool.

8.

Daily - Air Supply Maintenance:

Every day, perform maintenance on

the air supply according to the manu-

facturers’ instructions. Performing

routine maintenance on the air sup-

ply will allow the tool to operate more

safely and will also reduce wear on

the tool.

9.

Quarterly (every 3 months) - Tool

Disassembly, Cleaning, and In-

spection:

Have the internal mechanism cleaned

and inspected by a qualified techni-

cian.

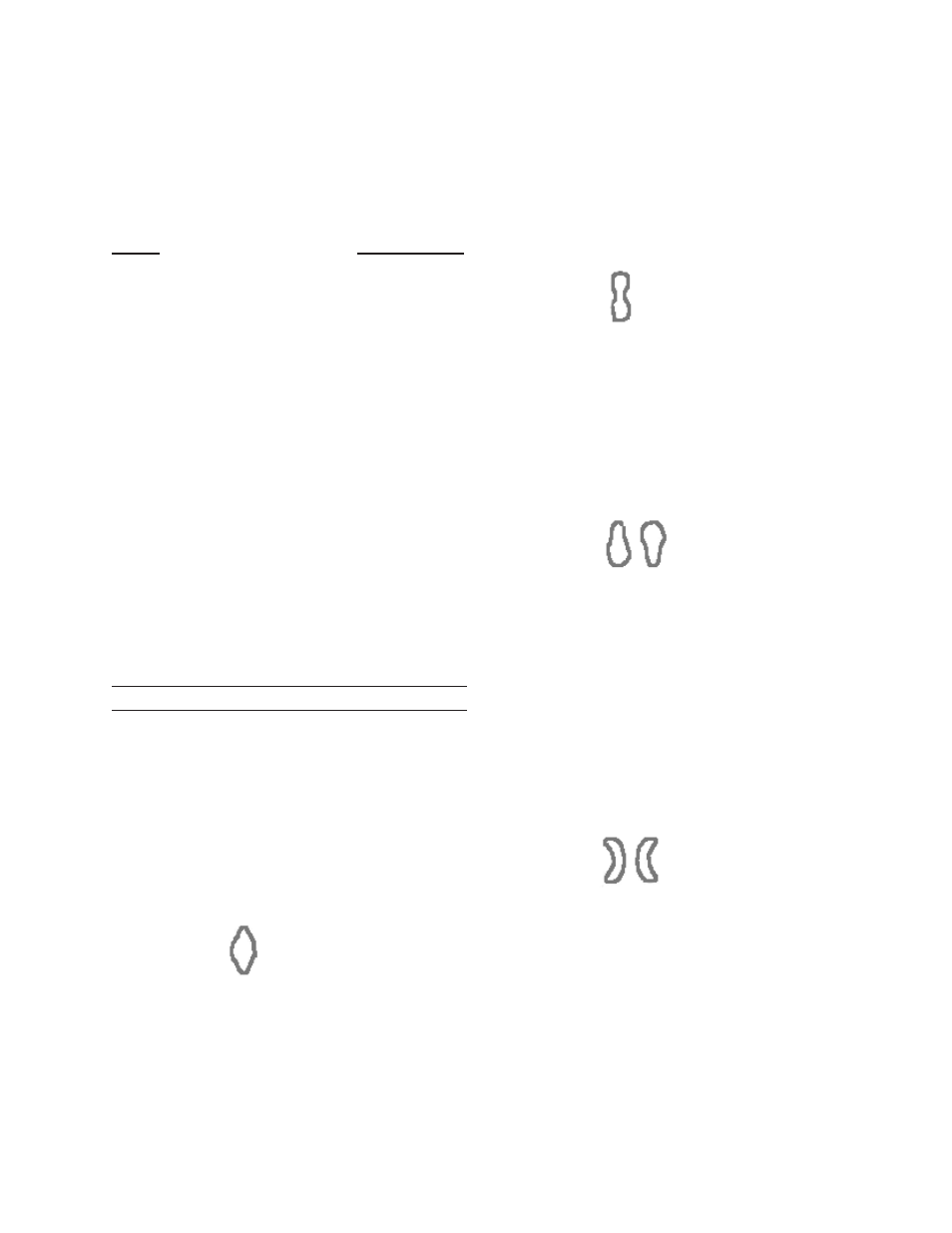

TROUBLESHOOTING

Spray Pattern Diagnosis

The Patterns below resemble

symptoms of spray pattern problems.

Please refer to the accompanying

possible problems if you are

experiencing similar difficulties. The

solution to each problem follows the

problem in parentheses.

Problem 1:

1. The Pattern Control Knob (10) is par-

tially closed. (Open Pattern Control

Knob (10).)

2. The material is too thick. (Thin mate-

rial according to the manufacturer’s

instructions.)

3. The air pressure is too low. (Increase

air pressure within the Maximum PSI

(115).

Problem 2:

1. High air pressure. (Reduce air pres-

sure.)

2. Not enough fluid. (Increase fluid.)

3. Pattern Control Knob (10) open too

much. (Partially close Pattern Control

Knob (10).)

Problem 3:

1. Air Cap (1) plugged. (Clean the Air

Cap (1).)

2. Air cap (1) loose or dirty seat. (Clean

Air Cap and threads with a stiff bristle

brush such as an old toothbrush,

wipe, reinstall and tighten.)

3. Dried material on Fluid Nozzle (4).

(Use a nonmetallic point to clean the

Fluid Nozzle (1).

Problem 4:

1. Dirt on one side of the fluid nozzle.

(Clean the fluid nozzle.)

2. Holes on one side of the Air Cap (1)

are plugged. (Clean the Air Cap (1)

with a nonmetallic point.) Some of

the holes in the Air Cap (1) are very

small. You may want to consider an

ultrasonic cleaner for this job.