Installation, Space for fixing, Cooker hoods – Hotpoint EG94 User Manual

Page 28: Unpacking the cooker, Levelling, Stability chain, Connecting to gas supply

28

GB

Installation

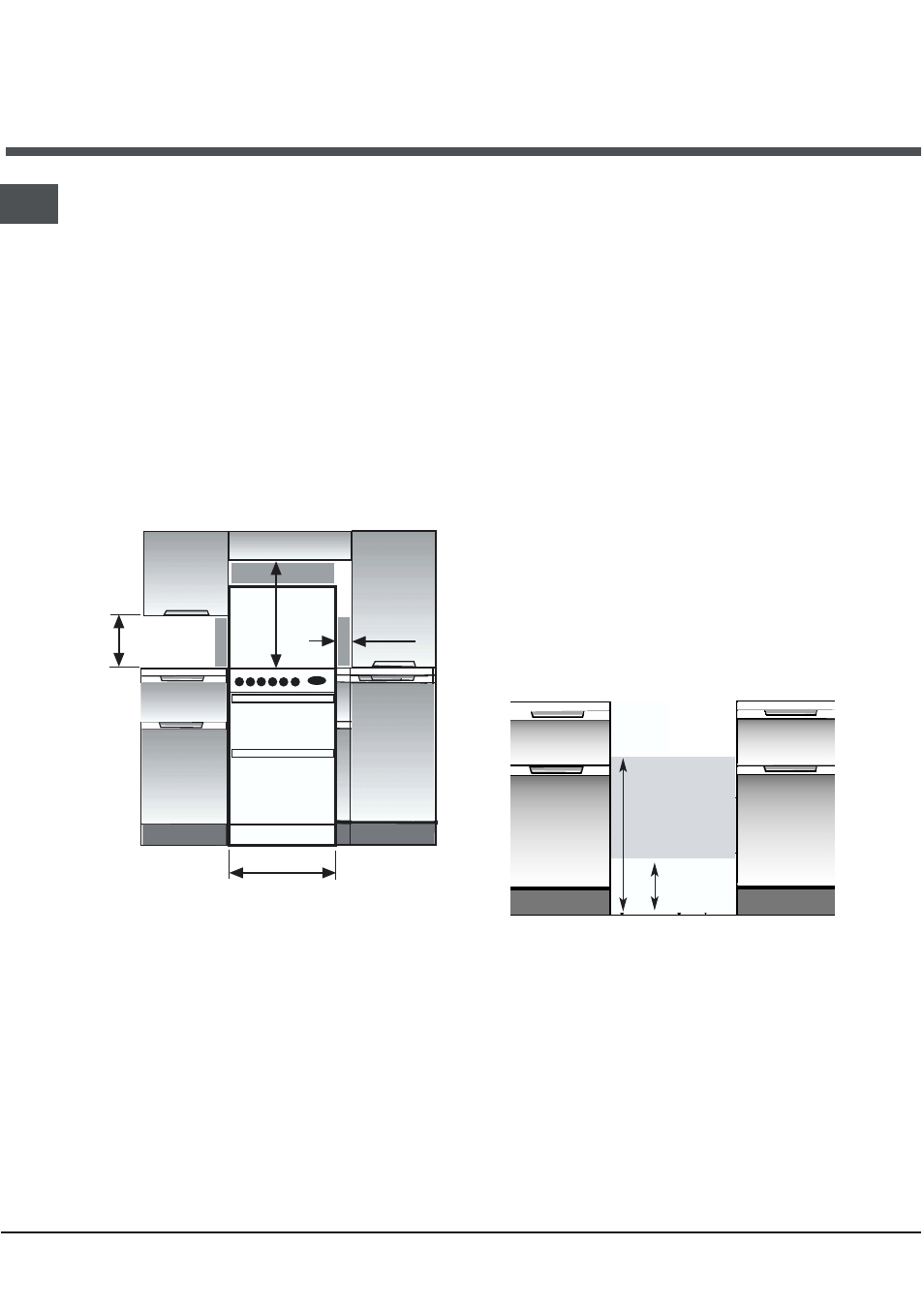

SPACE FOR FIXING

The cooker can be close fitted below hotplate level.

This requires a minimum distance of 600mm between

cupboard units of hotplate height.

When installing next to a tall cupboard, partition or

wall, for a minimum distance of 400mm above hotplate

level, allow a side clearance of at least 65mm.

The diagram below illustrates the minimum

clearance between the cooker and adjacent walls,

cupboards etc.

The wall behind the cooker, 50mm below and 450mm

above, and the width of the cooker, must be a non-

combustible material such as ceramic wall tiles.

If the cooker is to be fitted close to a corner on the

left hand side, ensure that there is a clearance of at

least 50mm to allow the main oven door to open fully

for when removing oven shelves.

65 mm Min

840 mm Min

400 mm Min

600 mm Min

750mm M

in

COOKER HOODS

If a cooker hood is to be installed, refer to the

cooker hood manufacturers' instructions regarding

fixing height.

UNPACKING THE COOKER

Unpack the components from inside the grill and

oven.

Check that the following parts are present:

Grill pan and grid

Aluminium burner bodies(4)

Baking dish

Pan supports

Main oven shelves (2)

Enamelled burner caps (5)

Top oven/grill shelf (1)

Literature

LEVELLING

Four skid feet are fitted which can be adjusted up or

down to level the cooker.

CONVERSION FOR USE ON BUTANE

(G30) OR PROPANE (G31)

Each burner requires the injector to be replaced and

bypass screws adjusted or replaced as follows:

1. Remove the loose hotplate burner parts.

2. Using a 7mm socket, replace the hotplate injectors

as appropriate (see table on previous page).

3. Re-position the loose burner parts.

4. Carefully pull off the hotplate control knobs.

5. Using a narrow flat bladed screwdriver rotate the

bypass screws fully clockwise. The hotplate tap

bypass screws are located down the centre of the

spindle.

6. Re-assemble the control panel parts.

7. Secure the self-adhesive LPG conversion label over

the gas details on the data badge.

STABILITY CHAIN

A hole in the gas inlet valve bracket can be used to

engage a stability chain.

CONNECTING TO GAS SUPPLY

300

670

Connection to the cooker should be made with an

approved appliance flexible connection to BS 669. A

length of 0.9 to 1.25m is recommended. The length

of hose chosen should be such that when the cooker

is in situ, the hose does not touch the floor.

Those cookers converted to use on LPG should be

connected with a hose suitable for LPG and capable

of withstanding a pressure of 50 mbar.

An adaptor backplate should be fitted within the

shaded area shown, to allow the cooker to be

pushed fully to the wall and to ensure that the

flexible hose is only likely to come into contact with

areas at the rear of the cooker that do not exceed a

temperature rise of 70°C.