Iquid, Itrogen, Lumbing – HP 11744195 User Manual

Page 13: Xhaust

Chart Environmental Chambers

System Installation

suction into the blower in the back wall of the chamber and discharge from the top of the

chamber.

❏

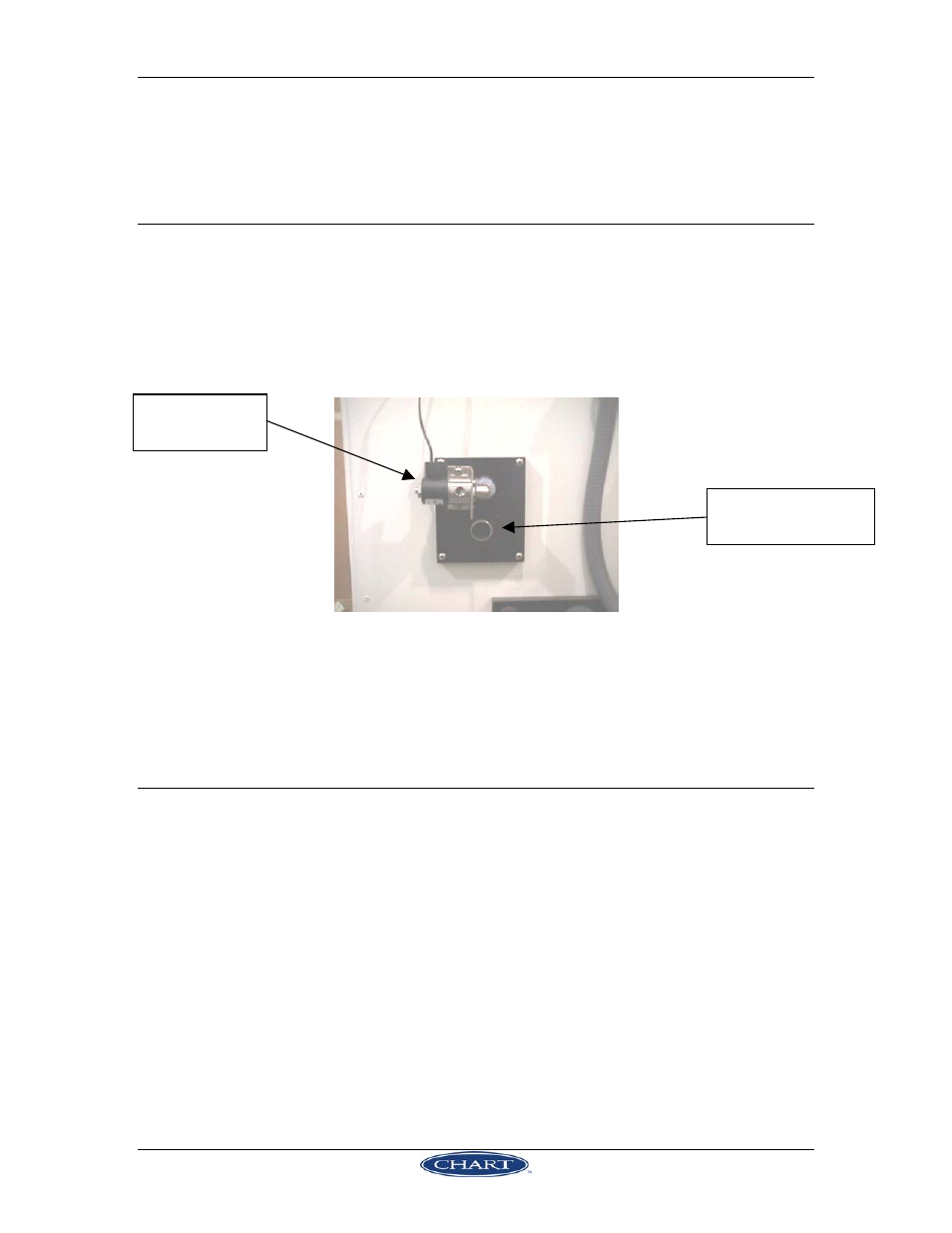

Liquid Nitrogen Plumbing

Along with the electrical power, bring in the LN

2

service from the top or the back of the

chamber for easy access around the chamber. The connection point is at the solenoid

valve on the back wall of the chamber. The nitrogen then flows through the valve and

then enters the chamber to supply liquid nitrogen to the nozzle inside the plenum. The

location of the liquid nitrogen inlet is dimensioned on the O&D drawing at the end of this

manual.

Liquid nitrogen

solenoid valve

Gaseous nitrogen

exhaust connection.

A line relief valve should be installed between the LN

2

connection on the chamber (the

solenoid valve) and the first manual shut-off valve upstream from this connection in the

nitrogen pipe system. This relief valve should be rated at a pressure less than 175 psig,

or the lowest pressure rated component in the system. This relief valve is not included

with the system and should be taken care of at installation.

❏

Exhaust Gas Plumbing

The exhaust gas of the chamber should be plumbed to the outside of the building. No

fans or restrictions should be placed in this line. Any fans or restrictions will decrease

system performance.

It is important to vent the system to the outside of the building for safety reasons. If the

system is not vented to the outside of the building, there is a risk of an oxygen-depleted

atmosphere in the area surrounding the chamber.

The vent piping should also be well insulated to prevent moisture present in the air from

condensing/freezing on the outside surface of the exhaust pipe. The exit of the exhaust

piping should be configured to prevent any water, rain, etc from flowing back into the

chamber’s exhaust system. Any water present in the system may form ice and break the

cooling heat exchanger.

8