Trigger installation, Safety opera tion maintenance setup – Harbor Freight Tools 67450 User Manual

Page 8

Page 8

For technical questions, please call 1-800-444-3353.

Item 67450

Initial Tool Set Up/Assembly

Read the ENTIRE IMPORTANT SAFETY INFORMATION section at the beginning of this

manual including all text under subheadings therein before set up or use of this product.

Note: For additional information regarding the parts listed in the following pages,

refer to the Assembly Diagram near the end of this manual.

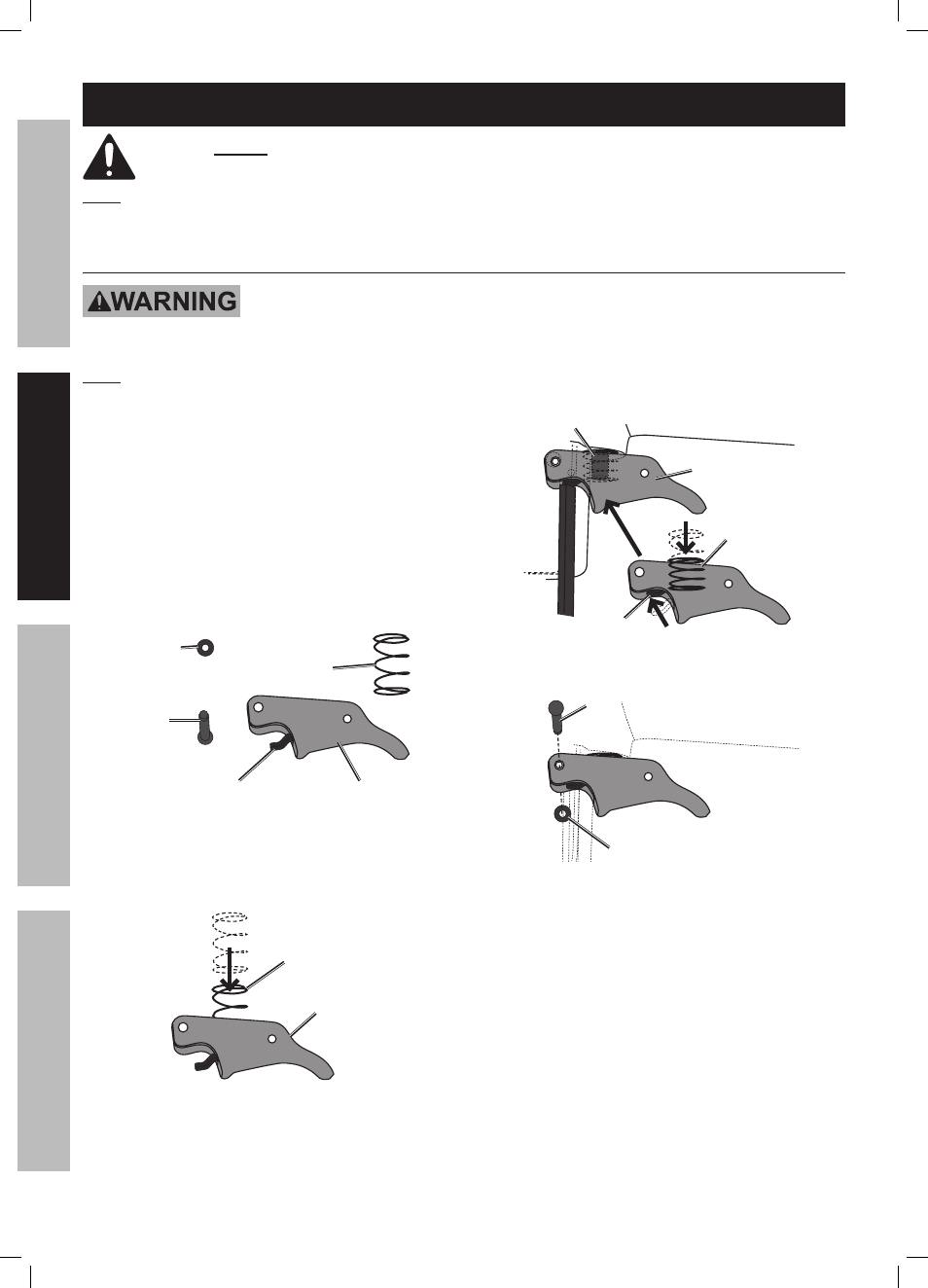

Trigger Installation

TO PREVENT SERIOUS INJURY FROM ACCIDENTAL FIRING:

Disconnect air supply, point nailer in a safe direction, and release pressure before changing trigger.

Note: This tool includes an additional trigger

to allow another triggering option.

• The

BLACK Trigger enables

full sequential operation.

This operation is

safer and should

be used whenever practical.

• The

RED Trigger enables

contact trip / bump fire operation.

This operation is more dangerous.

Only a skilled operator who is aware of the

hazards and uses proper, safe work practices

should use contact trip / bump fire operation.

1. Remove Pin and Rubber Ring from current Trigger.

Rubber

Ring

Pin

Trigger

Lever

Spring

Figure A: Trigger Components

2. Remove current Trigger. Remove Spring and

store unused Trigger in secure dry place.

3. Place Spring into desired Trigger.

Figure B: Spring Position

Trigger

Spring

4. Hold down Spring and Lever while

placing Trigger over valve stem.

Figure C: Installing Trigger

Spring

Trigger

Valve Stem

Lever

5. Insert Pin, and place Rubber Ring over end of Pin.

Figure D: Inserting Pin

Pin

Rubber

Ring

6. Check Trigger for proper operation and test safety

operation according to the instructions that follow.

SAFETY

OPERA

TION

MAINTENANCE

SETUP