Troubleshooting – Harbor Freight Tools PACIFIC HYDROSTAR 1/3 HP Submersible Sump Pump with Vertical Float Switch 68476 User Manual

Page 8

Page 6

For technical questions, please call 1-800-444-3353.

Sump Pump manual

Troubleshooting

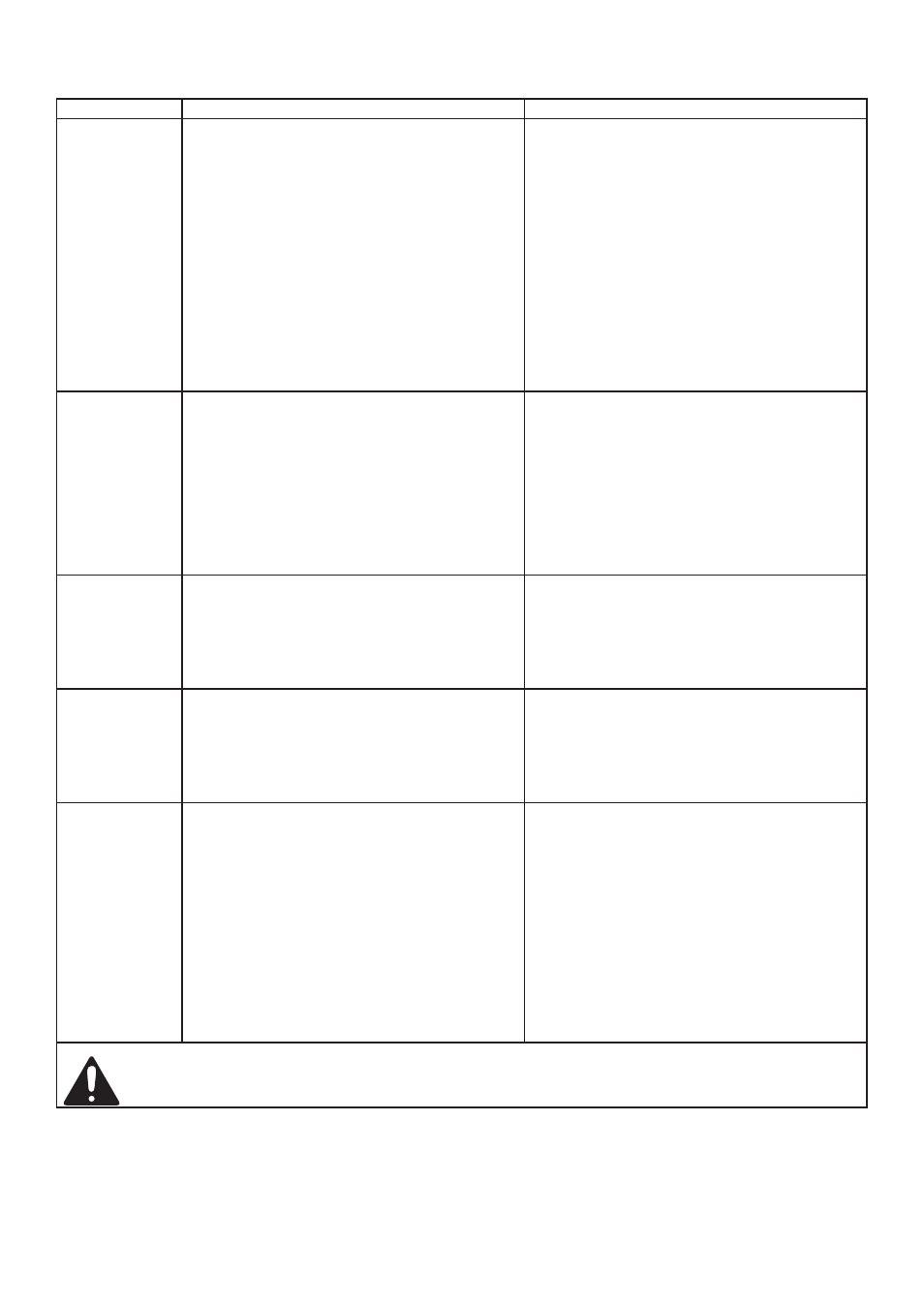

Problem

Possible Causes

Possible Solutions

Pump runs, but

will not deliver

any water.

Disconnect power cords immediately

to prevent damage from running dry.

1. Pump “airlock”.

Impeller trapped in an air bubble.

2. Shut off valve closed (if installed).

3. Filter clogged.

4. Impeller clogged.

5. Discharge Pipe frozen or blocked.

6. Optional check valve stuck or

installed backwards.

Disconnect power cords immediately

to prevent damage from running dry.

1. Drill a 3/16 IN. diameter air bleed hole

through the Discharge Pipe just

above the Lower Base.

2. Open valve.

3. Clean out dirt and debris from filter.

4. Remove Volute. Clean out dirt and debris

from Impeller. Then replace Volute.

5. Thaw pipe and/or remove debris.

6. Examine and correct check valve.

Pump won’t

start or run.

1. Check power connections and circuits/fuses.

2. Water level too low.

3. Filter clogged.

4. Impeller clogged.

5. Motor damaged or worn out.

1. Consult with an electrician.

2. Allow water level to rise above the

Float Switch Operation ON Height

or move Pump to a lower location.

3. Clean out dirt and debris from filter.

4. Remove Volute. Clean out dirt and debris

from Impeller. Then replace Volute.

5. Pump must be replaced.

Excessive noise

or vibration.

1. Debris in impeller.

2. Discharge pipe restricted.

3. Worn bearings.

1. Remove filter, if equipped.

Clean impeller. Then replace filter.

2. Clean pump and discharge pipe.

Straighten flexible hose.

3. Pump must be replaced.

Pump starts

and stops too

frequently.

1. Water temperature too high.

2. Back flow of water from discharge pipe.

3. Extension cord used.

1. Do not exceed 77° F (25°C).

2. Install or inspect optional check valve.

3. Eliminate use of extension cord.

Have licensed electrician install

GFCI-protected outlet near pump if needed.

Pump does

not shut off

automatically.

DISCONNECT POWER CORDS FIRST

TO PREVENT SERIOUS INJURY.

1. Pump Cord not connected through

Float Switch Cord plug.

2. Float Switch stuck.

3. Check valve not installed

properly or functioning.

4. Defective Float Switch.

DISCONNECT POWER CORDS FIRST

TO PREVENT SERIOUS INJURY.

1. Plug Pump Cord into back of

Float Switch Cord plug.

2. Check for free movement of Float Switch.

Clear debris away from beneath Float Switch.

3. Make sure check valve is properly

installed and in working order.

4. Unplug Pump from its electrical outlet.

Do not use until qualified technician

checks Pump for proper operation.

Follow all safety precautions whenever diagnosing or servicing the tool.

Disconnect power supply before service.