Pressure control valve – I.C.T.C. Holdings Corporation 300S Legend User Manual

Page 30

H.E.R.O. INDUSTRIES

300S / 300SL LEGEND Owner’s Manual

30

1

Remove pressure control knob, (ref# 74) and pull P.C. stem, (ref# 77) out to the internal stop (1/16" to

1/8") thereby releasing hydraulic pressure.

2

Remove hydraulic return line, (ref# 72) from P.C. fitting, (ref# 81).

3

Place 11/16" wrench on P.C. seat, (ref# 87). Turn counter-clockwise to remove complete valve.

4

Place complete valve in vise and remove seat from body, (ref# 81).

5

Remove ball, (ref# 86), retainer, (ref# 85), and spring, (ref# 84) from body. Inspect ball for nicks or cuts

and replace if damaged. Inspect seat at sealing edge, for signs of wear. A good condition seat will have a

very small beveled at the sealing edge. The larger the bevel the more wear has taken place. Inspect

retainer for wear. The retainer has a small locating hole in it. The hole should be flush or slightly

beveled. The greater the wear on the ball, seat, and retainer the poorer the static pressure will be. Replace

parts individually, or use repair kit, (ref# 88).

6

Hold P.C. body vertical. Place spring into body, place retainer onto spring. Ensure retainer fits

completely over spring. Retainer should rest below end of body by approximately 1/4" to 3/8". Place ball

onto retainer, ensuring ball is located on center hole.

7

Thread on seat, using care not to dislodge the ball from its position on the retainer. Tighten firmly.

8

Apply pipe dope or Teflon tape to exterior threads of seat. Install into elbow. Tighten to prevent leaks

and return to original position.

9

Reattach hydraulic line. See "PURGING" instructions on page 19.

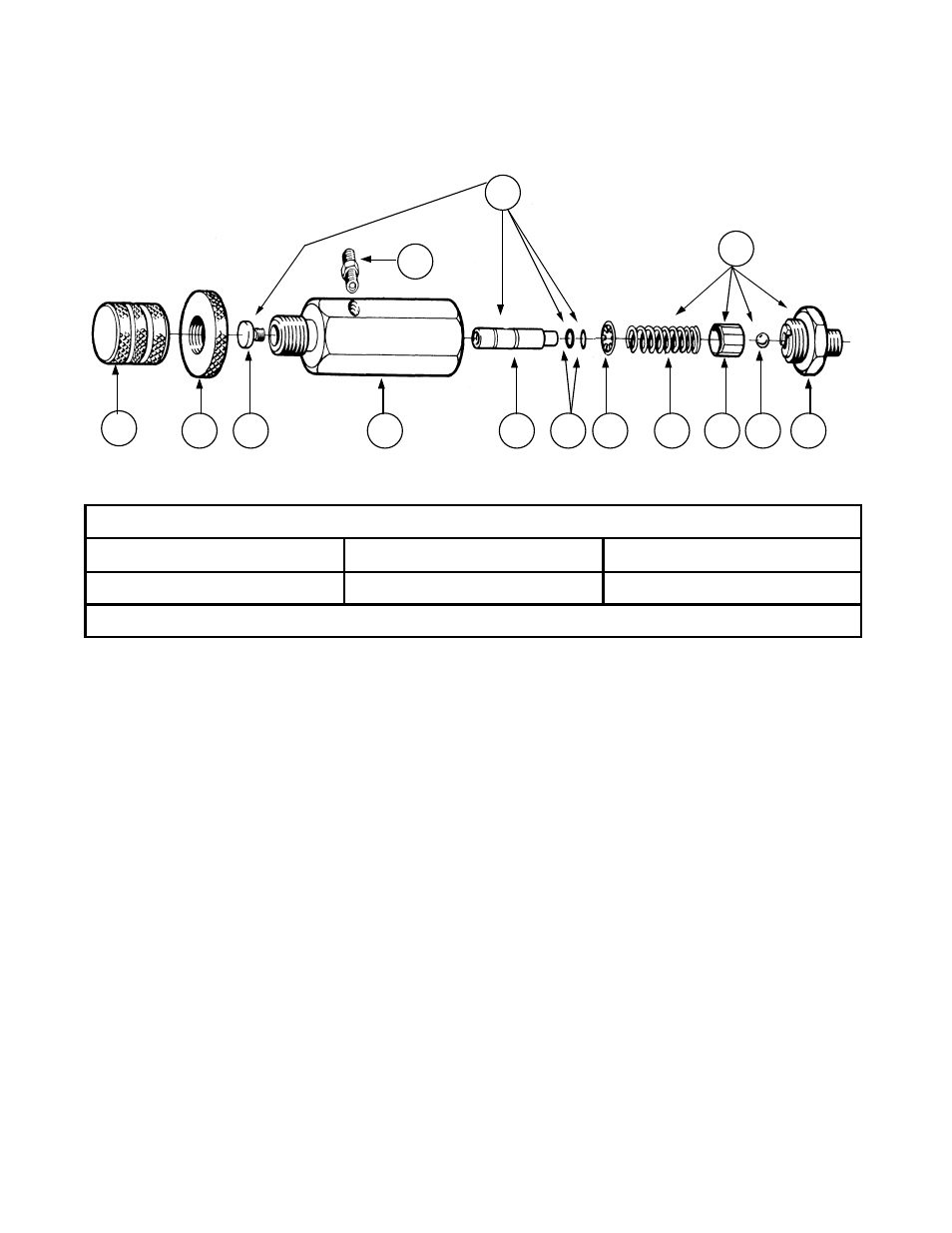

80

78

81

82

79

76

86

85

84

83

87

88

77

74

PRESSURE CONTROL VALVE

Tools or Supplies Required

♦

Vise

♦

11/16” Open end wrench

♦

H.E.R.O. hydraulic oil

♦

7/16” Open end wrench

♦

1” Open end wrench

♦

4-45-3 Pressure cap

♦

Teflon Tape or pipe sealant, optional *