I.C.T.C. Holdings Corporation 300S Legend User Manual

Page 3

H.E.R.O. INDUSTRIES

300S / 300SL LEGEND Owner’s Manual

3

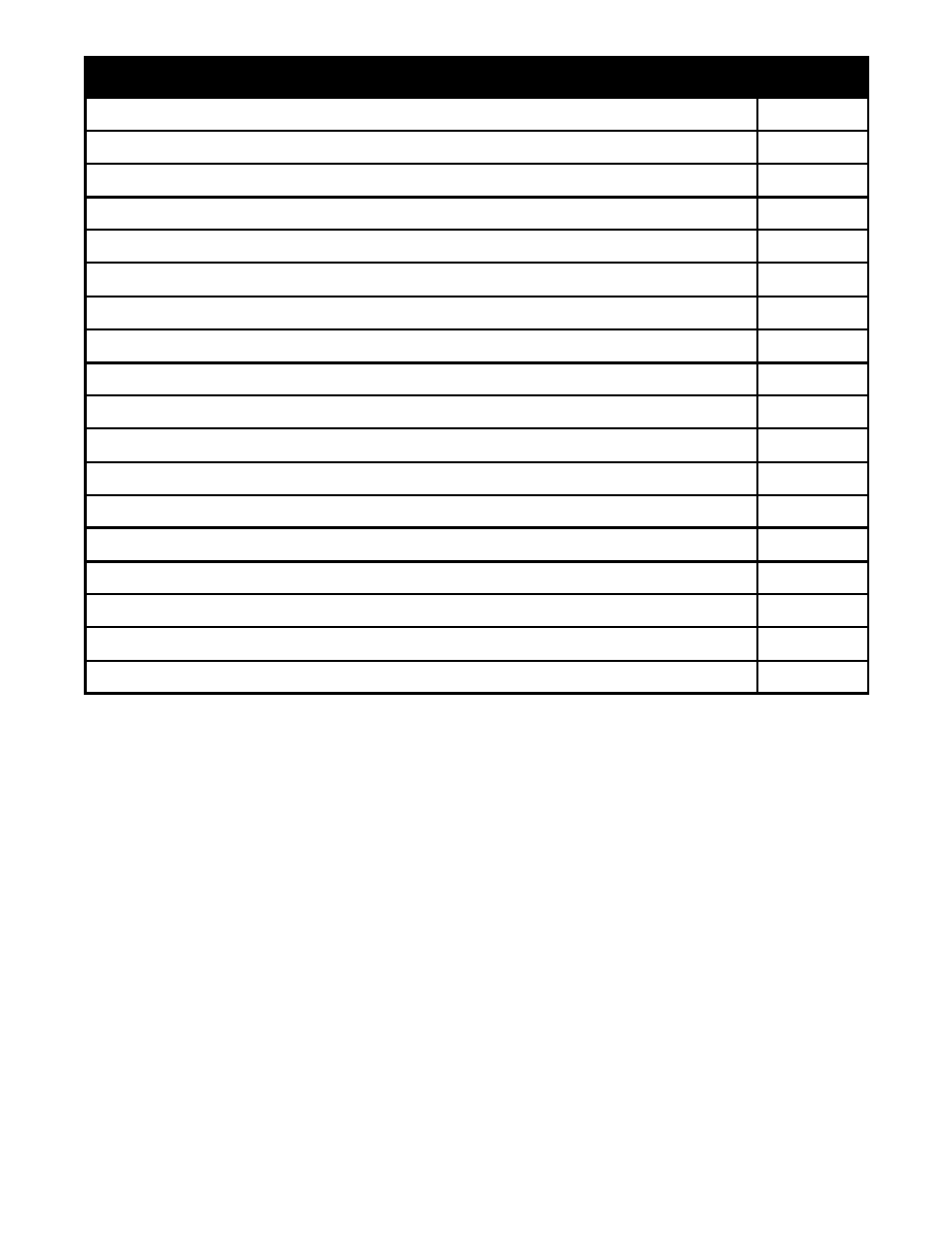

Table of Contents

Important Safety Precautions

4 – 5

Introduction

6

Operating Instructions

6

Setting up to Spray

7

Flushing The Unit

8

Special Notes

9

Airless Spray Painting Suggestions

10 – 13

Trouble Shooting

14 – 22

Intake Seat Replacement

23

Outgo Valve

24

Bleed Valve Repairs

25

Diaphragm Replacement

26

Hydraulic Head Insert Replacement

27

Piston Repairs

28 – 29

Pressure Control Valve Repairs

30

Accessories

31

Parts List & Description

32 – 36

Exploded Unit Schematics

37 – 38

IMPORTANT

AS WITH ALL MECHANICAL EQUIPMENT, PROPER OPERATING AND MAINTENANCE

PROCEDURES ARE REQUIRED TO KEEP YOUR H.E.R.O. AIRLESS PUMP PERFORMING

TO YOUR SATISFACTION. THE FOLLOWING SAFETY, OPERATING AND MAINTENANCE

INSTRUCTIONS ARE IMPORTANT.

Read and understand this manual completely, especially with regard to all safety precautions. Read and

follow instructions on all warning labels on your equipment. Keep the warning labels clean and readable at

all times. Order new labels from your local distributor or from H.E.R.O. Industries if needed.

The manufacturer shall not be responsible for any loss, damages, or injury of any kind or nature whatsoever

resulting from the use the equipment other than in strict compliance with the instructions, cautions and

warnings contained in this operating and instruction manual and as displayed on the face of the equipment.

This system is capable of producing 2400 psi. ( spray pressure ). To avoid rupture and injury DO NOT

operate this pump with components rated less than 3000 psi. working pressure (including but not limited to

spray guns, hose and connections).

Before servicing, cleaning or removing of any part, shut off power and relieve pressure.