Hustler Turf 60 User Manual

Page 21

601457_1107

19

Closed

position

Fuel system

DANGER:

Observe usual fuel handling precautions:

Do not smoke while refueling. Extinguish all cigarettes, cigars,

pipes andother sources of ignition.

Do not remove fuel cap or fill tank with engine running or

while engine is hot. Clean up any gasoline spills.

Allow engine to cool before storing machine inside a building.

Keep fuel away from open flame or spark and store machine

away from open flame or spark or pilot light such as on a water

heater or other appliances.

Use extreme care when handling gasoline and other fuels.

They are extremely flammable and vapors are explosive. A fire

or explosion from gasoline can burn you and others and can

damage property.

Never refuel or drain the fuel from the machine indoors.

Never attempt to start engine when there is a strong odor of

gasoline fumes present. Locate and correct cause.

Store gasoline in an approved container and keep it out of the

reach of children. Never buy more than a 30 day supply of gas-

oline.

Always place gasoline containers on the ground away from

your vehicle before filling.

Do not fill gasoline containers inside a vehicle or on a truck or

trailer bed with interior carpets or plastic truck bed liners.

Always place gasoline containers on the ground away from

your vehicle before filling.

When practical, remove gas-powered equipment from the truck

or trailer and refuel the equipment with its wheels on the

ground. If this is not possible, then refuel such equipment on

the truck or trailer using a portable container and not a gasoline

dispenser nozzle. If a gasoline dispenser nozzle must be used,

keep the nozzle in contact with the rim of the fuel tank or con-

tainer opening at all times until fueling is complete. Do not use

a nozzle lock-open device.

Read and observe safety precautions elsewhere in this manual.

WARNING:

Gasoline is harmful or fatal if swallowed.

Long-term exposure to vapors can cause serious injury and ill-

ness.

Avoid prolonged breathing of vapors.

Keep face away from nozzle and gas tank or fuel container

opening.

Keep gas away from eyes and skin.

If fuel is spilled on clothing, change clothing immediately.

The fuel tanks are located in the tractor’s fenders.

Use regular unleaded gasoline with an octane rating of 87 or higher.

IMPORTANT:

Never use methanol, gasoline containing methanol, or gaso-

hol containing more than 10% ethanol because the fuel system could be dam-

aged. Do not mix oil with gasoline.

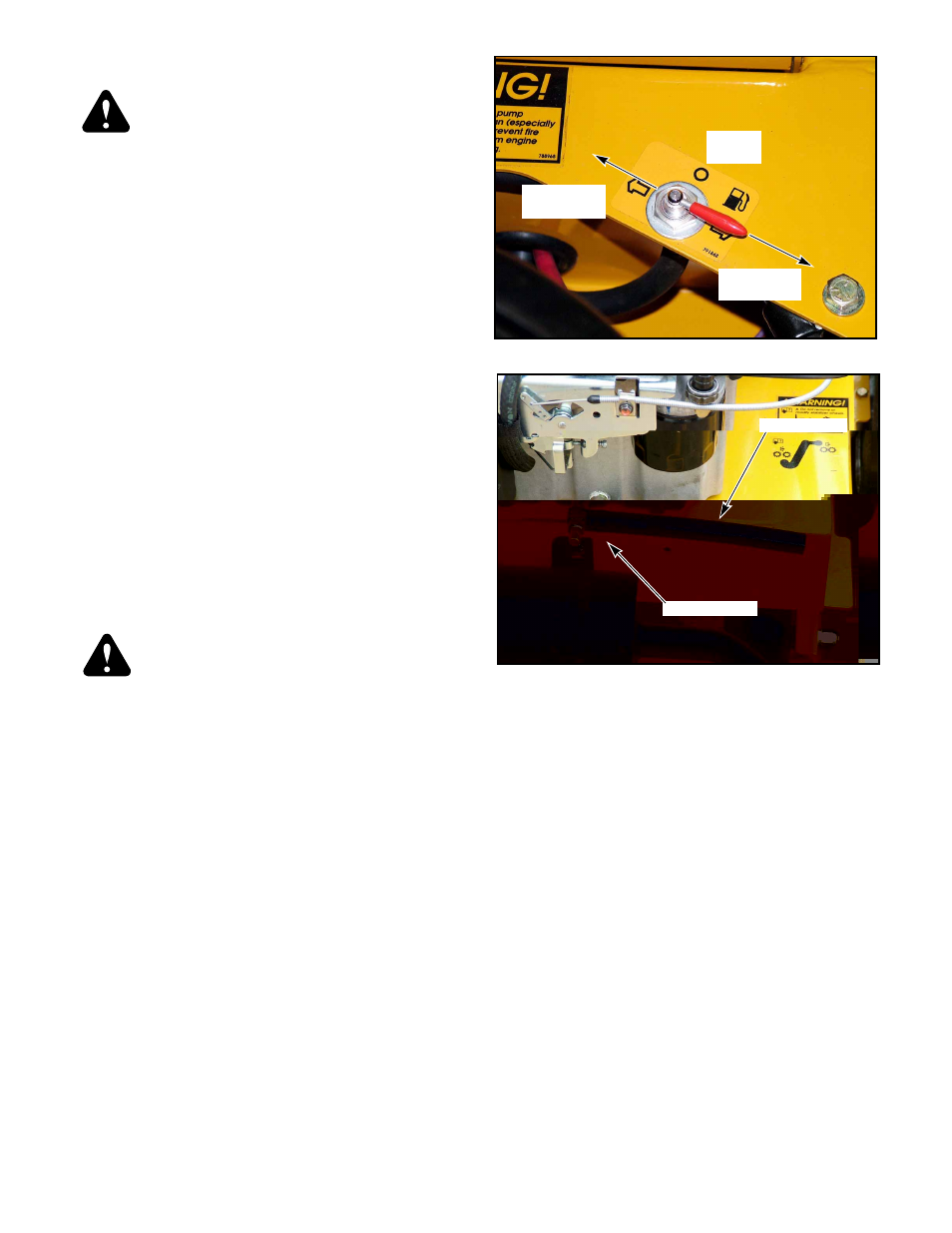

A fuel shut-off valve is located on each tractor. The location and opera-

tion of the fuel valve will vary depending upon the unit. Close the fuel valve

to prevent fuel flow to the engine. The valve’s two other positions will allow

fuel to be drawn from either one or the other fuel tank. 4-3

IMPORTANT:

Do not overfill the fuel tanks. The fuel tanks should be

filled no higher than 2” (5.08 cm) below the tank’s fill neck.

Engine oil and filter

Check engine oil daily and after every 4 hours of operation. Tractor must

be setting level when checking oil. Refer to engine manual and maintenance

schedule for oil recommendation and capacities.

Change the engine oil and filter after the first 5 hours of operation, per the

engine manufacturer’s recommendations after that. If tractor is being oper-

ated in extremely dirty conditions, then it is recommended oil be changed

more frequently.

IMPORTANT:

When removing the oil filter take precau-

tions to minimize oil spillage on the exhaust system.

Attach the oil drain hose, furnished with the unit, to the oil drain valve

when draining the engine oil. Oil drain hose must be removed after oil is

drained.

IMPORTANT:

All oil drips or spills must be cleaned off of the

exhaust system before operating the machine. Fig. 4-5

Engine air filter

Perform engine air filter maintenance per the Service Interval chart

shown elsewhere in this manual.

A specially designed dry filter is standard equipment on these tractors

and supplies clean combustion air to the engine. Fig. 4-5

These units are equipped with a safety filter. The filter element slides

over the safety filter.

NOTE:

The safety filter does not require servicing unless it becomes

contaminated with dirt or moisture.

Recommended service procedure

1. Release clamps and remove element. Clean the canister with a damp

cloth.

2. Before installing a new element, inspect it by placing a bright light inside

and rotate the element slowly, looking for any holes or tears in the paper.

Also check gaskets for cuts or tears. Do not attempt to use a damaged

element which will allow abrasive particles to enter the engine.

3. Reinstall the dust cup. Make sure it seals all the way around the air

cleaner body, then tighten the clamps.

4. Check all fittings and clamps periodically for tightness and inspect hoses

for holes or cracks.

5. Periodically check the intake hose for signs of ingested dust. Locate and

repair the source of ingested dirt.

6. Never operate a machine without an air filter installed.

Overservicing

Overservicing occurs when an air filter element is removed for cleaning

or replacement before it is necessary. Each time the filter is removed a small

amount of dirt and dust could fall in the intake system. This accumulated dirt

Figure 4-3

Right fuel

tank position

Left fuel tank

position

Figure 4-4

Oil drain hose

Oil drain valve