Troubleshooting – Harbor Freight Tools ONE STOP GARDENS 95690 User Manual

Page 6

Page 6

For technical questions, please call 1-800-444-3353.

Item 95690/95692

inspection, maintenance, and Cleaning

procedures not specifically explained in this manual must

be performed only by a qualified technician.

Do not use damaged equipment. if abnormal noise, vibration, or

leaking air occurs, have the problem corrected before further use.

Follow all guidelines regarding chemicals sprayed, including mSDS instructions and Epa regulations.

Release pressure in tank by pulling up on the pressure Release Valve before loosening

or removing parts. Contents are under pressure and may spurt forcefully.

1.

BEFORE EaCh uSE, inspect the general

condition of the Sprayer. Check for:

• loose hardware,

• misalignment or binding of moving parts,

• cracked or broken parts, and

• any other condition that may

affect its safe operation.

2.

aFtER EVERY uSE, Clean the Sprayer:

a. Flush with water.

b. Clean Nozzle and Filter (35).

c. Rinse with water and allow to air-dry.

3.

pERiODiCallY, lubricate all moving parts of

the pump assembly with petroleum jelly.

4. Store the Sprayer in a safe, dry, clean location

out of reach of children and out of sunlight.

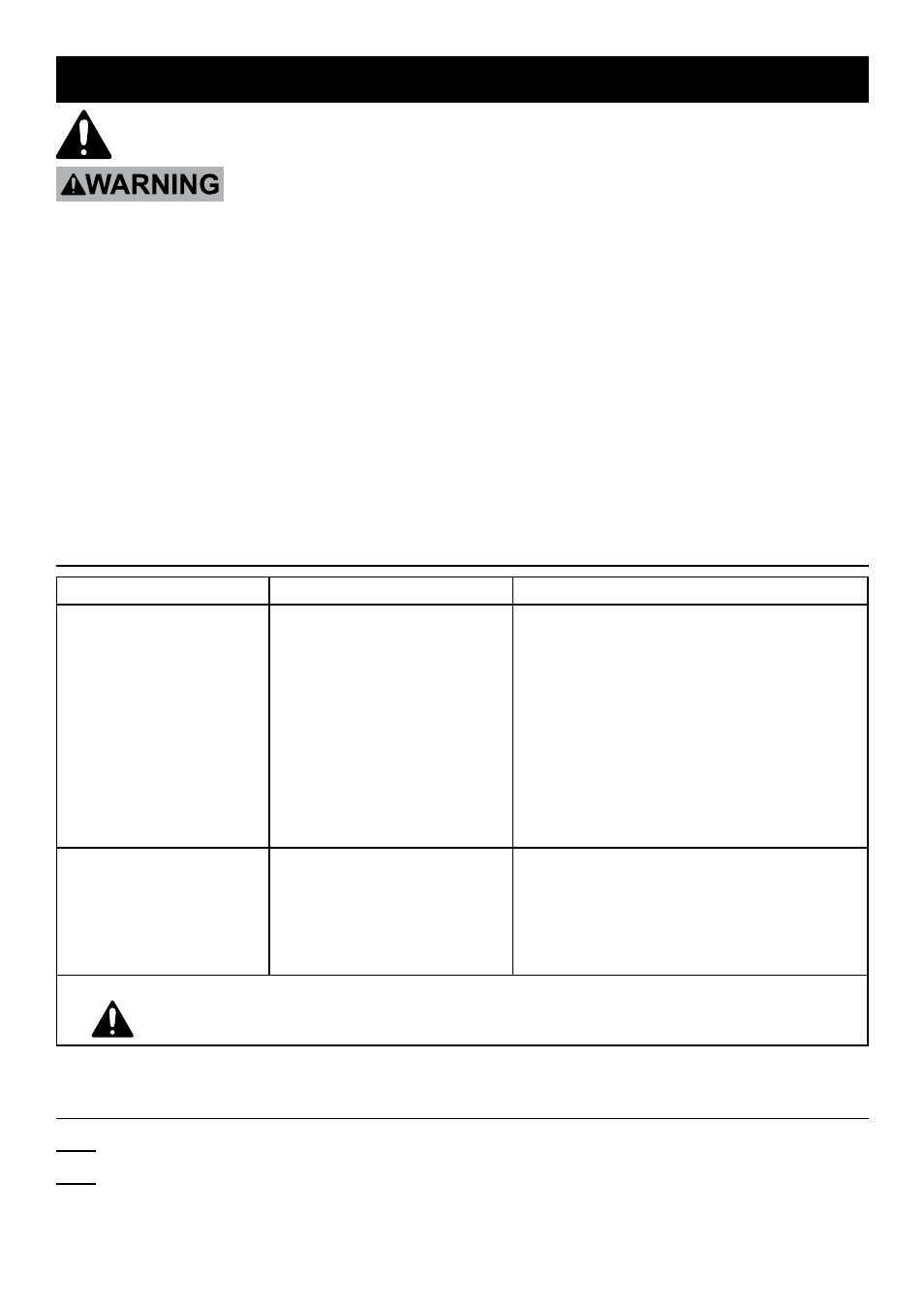

troubleshooting

problem

possible Causes

likely Solutions

Unit does not spray

1. Suction Tube (34) detached.

2. Not enough liquid in tank.

3. Handle Assembly loose.

4. Hose Nut (18) loose.

5. Safety Cap (22) loose.

6. Sprayer not pressurized.

7. Spray fluid contains

particles or sand.

8. Nozzle and/or Filter clogged

with mineral buildup.

1. Reattach Suction Tube.

2. Add liquid to tank.

3. Tighten Handle Assembly.

4. Tighten Hose Nut.

5. Tighten Safety Cap.

6. Pump Handle to pressurize Sprayer.

7. Disassemble, clean, then reassemble

Nozzle and/or Filter. Empty, clean, then

refill Tank with properly strained fluid.

8. Disassemble, clean, then reassemble

Nozzle and/or Filter.

Spray pattern is undesirable

1. Nozzle needs adjustment.

2. Spray fluid contains

particles or sand.

3. Nozzle and/or Filter clogged

with mineral buildup.

1. Adjust Nozzle.

2. Disassemble, clean, then reassemble

Nozzle and/or Filter. Empty, clean, then

refill Tank with properly strained fluid.

3. Disassemble, clean, then reassemble

Nozzle and/or Filter.

Follow all safety precautions whenever diagnosing or servicing the Sprayer.

Record Serial number here:

note: if product has no serial number, record month and year of purchase instead.

note: Some parts are listed and shown for illustration purposes only, and

are not available individually as replacement parts.