12. weld test, 13. troubleshooting – Hobart Welding Products CHAMPION ELITE OM-240 438E User Manual

Page 60

OM-240 438 Page 56

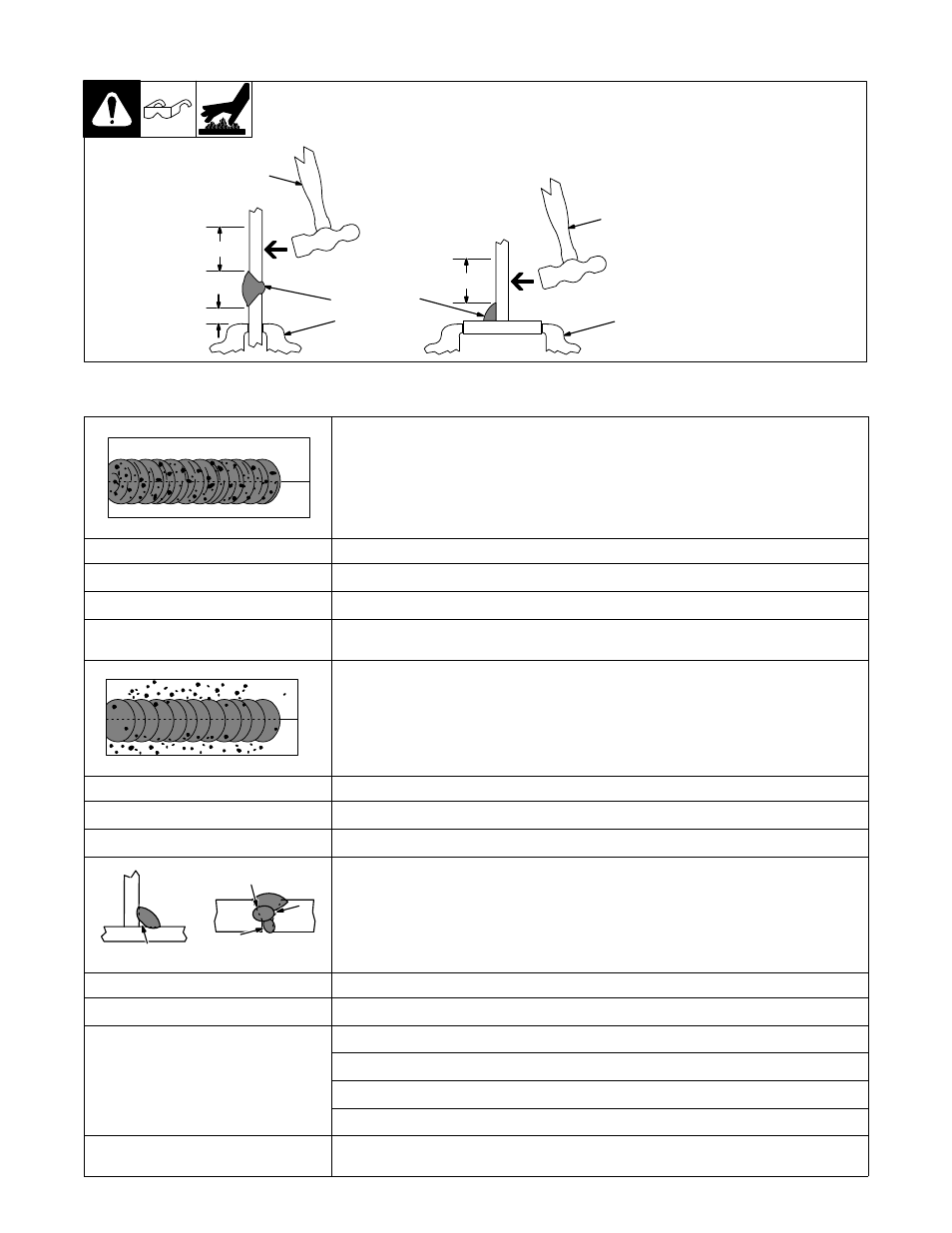

13-12. Weld Test

S-0057-B

1

Vise

2

Weld Joint

3

Hammer

Strike weld joint in direction shown.

A good weld bends over but does

not break.

2 To 3 in.

1/4 in.

3

2

1

2 To 3 in.

3

2

1

(51-76 mm)

(6.4 mm)

(51-76 mm)

13-13. Troubleshooting

Porosity − small cavities or holes resulting from gas pockets in weld metal.

Possible Causes

Corrective Actions

Arc length too long.

Reduce arc length.

Damp electrode.

Use dry electrode.

Workpiece dirty.

Remove all grease, oil, moisture, rust, paint, coatings, slag, and dirt from work surface before

welding.

Excessive Spatter − scattering of molten metal particles that cool to solid form near weld bead.

Possible Causes

Corrective Actions

Amperage too high for electrode.

Decrease amperage or select larger electrode.

Arc length too long or voltage too high.

Reduce arc length or voltage.

Incomplete Fusion − failure of weld metal to fuse completely with base metal or a preceeding

weld bead.

Possible Causes

Corrective Actions

Insufficient heat input.

Increase amperage. Select larger electrode and increase amperage.

Improper welding technique.

Place stringer bead in proper location(s) at joint during welding.

Adjust work angle or widen groove to access bottom during welding.

Momentarily hold arc on groove side walls when using weaving technique.

Keep arc on leading edge of weld puddle.

Workpiece dirty.

Remove all grease, oil, moisture, rust, paint, coatings, slag, and dirt from work surface before

welding.