Boiler room, Chimney connections, Installation – Heatmaster 201 User Manual

Page 10

8

BOILER ROOM

Important

• Keep vents free at all times.

• Do not store inflammable products in the boiler room.

• Do not store corrosive products near the boiler, such as paints,

solvents, chlorine, salt, soap and other cleaning products.

• If you smell gas, do not switch on the light or light a flame. Turn off

the mains gas tap at the meter and inform the appropriate

services immediately.

Access

The boiler room must be large enough to allow good access to the

boiler. The following minimum distances are required around the

boiler:

- front

500 mm

- side

100 mm

- behind

150 mm

- above

350 mm

Ventilation

The boiler room must have both low- and high-level ventilation,

in accordance with the local standards and provisions force.

The table below gives an example conforming to the Belgian standards.

Other countries should refer to their own standards.

Base

The base on which the boiler rests must be made of non-combustible

materials.

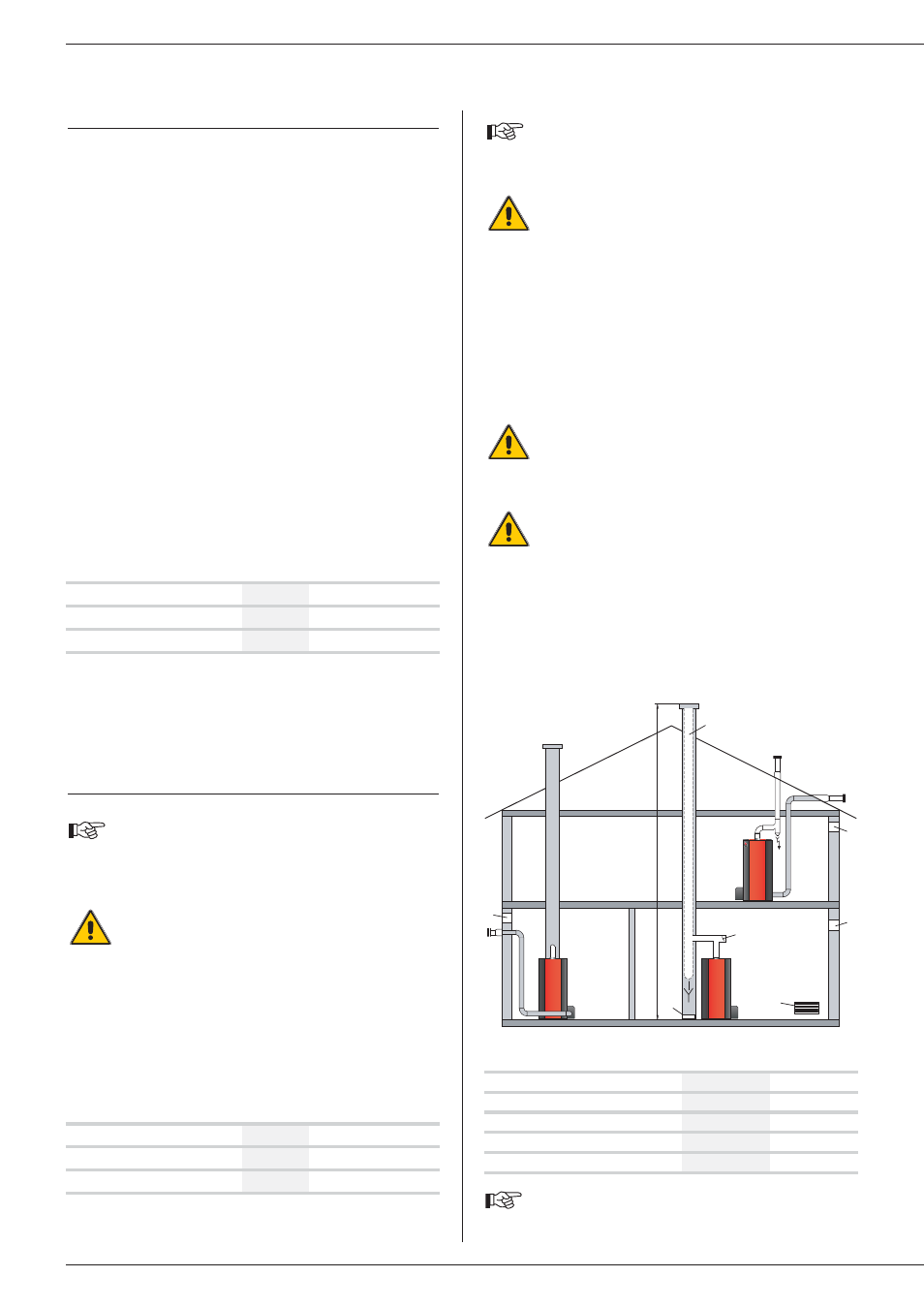

CHIMNEY CONNECTIONS

IMPORTANT

Boilers must be installed by an approved heating

engineer, in accordance with the prevailing local

standards and regulations.

The duct size may not be smaller than the boiler outlet

duct.

Typical boiler connection: B23

The boiler is connected to the chimney by a metal pipe rising at an

angle from the boiler to the chimney.

A flue disconnection piece is required.

This must be easy to remove to give access to the flue pipes when

servicing the boiler.

INSTALLATION

Ventilation

201

Min. fresh air requirement

m

3

/h

436

Bottom

dm

2

2.45

Top

dm

2

7.30

Chimney / minimum flue diameter

201

E = 5 m

Ø F min.

mm

350

E = 10 m Ø F min.

mm

300

E = 15 m Ø F min.

mm

270

Note:

Regulations vary from country to country therefore

the table above is intended only as a guide.

Due to the high efficiency of our boilers, the flue gasses

exit at low temperature. Accordingly, there is risk that

the flue gasses could condense, which could damage

the chimney. In order to avoid this risk, it is strongly

recommended that the chimney be lined.

Connecting the boiler to an air vent type: C

• C53: parallel connection

total loss of pressure (air intake + flue-gas discharge) may not exceed

250 Pa. See the table below showing the pressure drops for the various

components.

A condensation drain outlet must be fitted close to the

boiler to prevent condensation products from the

chimney running into the boiler.

To avoid condensation water running out of the

terminal, all horizontal flue runs must fall back towards

the boiler.

C53

B23

D

C53

A

A

A

B

C

F

E

A. Top vent

B. Bottom vent

C. Draught regulator

D. Inspection window

E. Height of lined chimney

F. Chimney diameter

Air

Flue gas

Ø 100 mm

Ø 250 mm

Pipe, L. 1000mm

18.0

1.0

90° bend 70.0

3.0

45° bend 28.0

-

Condensates trap

-

5.0

Terminal

50.0

3.0

When connecting the flue gas outlet to an existing

chimney, do not take into account the pressure drop

on the “flue gas side”.