Safety opera tion maintenance setup – Harbor Freight Tools Central Machinery 5 Speed Bench Drill Press with Work Light 60238 User Manual

Page 9

Page 9

For technical questions, please call 1-800-444-3353.

Item 60238

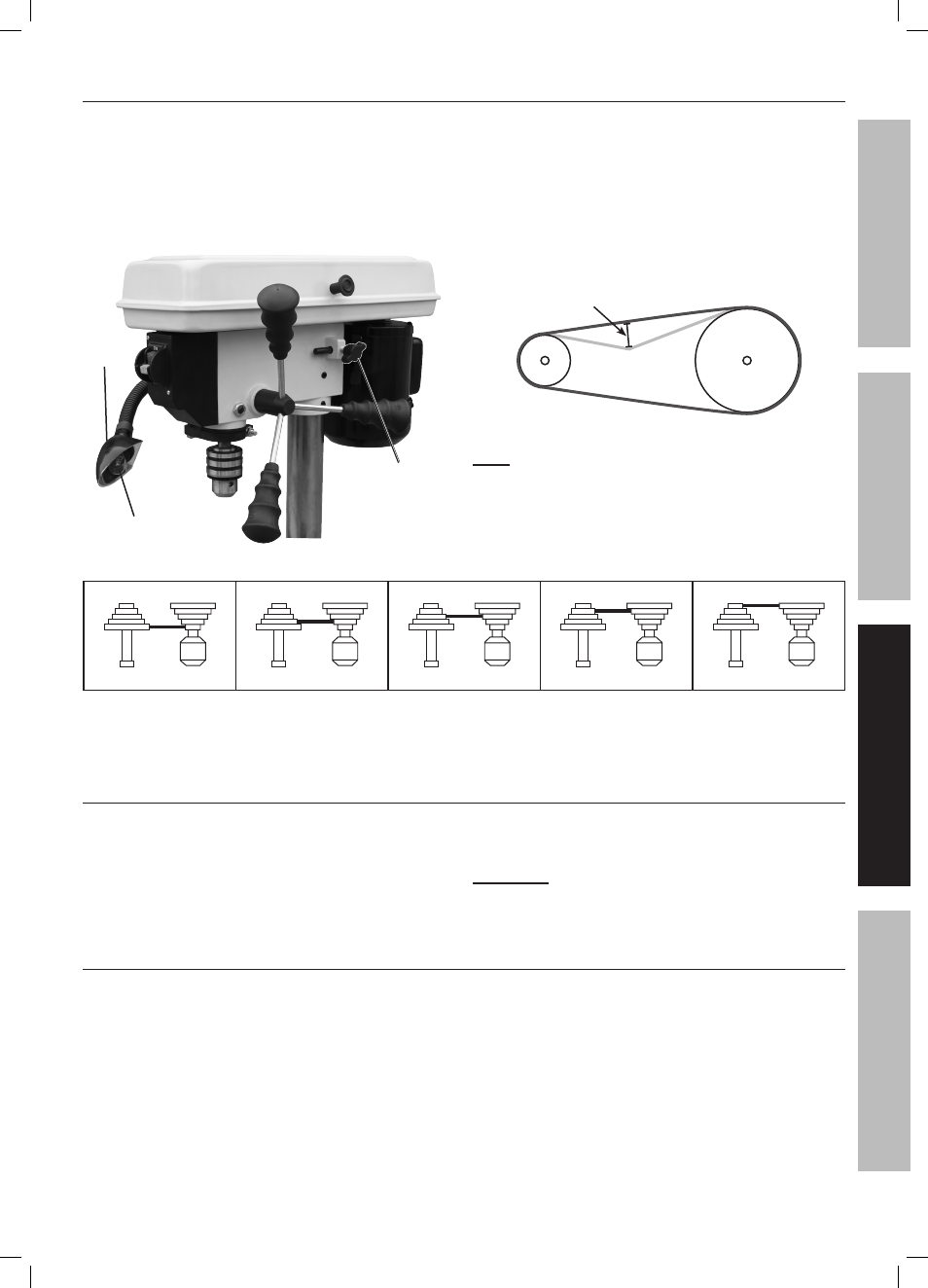

Changing Drill Speed

Before changing the speeds, make sure the

machine is switched OFF and UNPLUGGED.

1. Open the pulley cover.

2. Loosen the Motor Tension Knob (10) on the

Headstock (42), and move the Motor (14) towards

the Headstock to relieve tension on the Belt (59).

Motor Tension

Knob (10)

Light Bulb (73)

Lamp

(34)

Figure F: Motor Tension Knob location

3. Consult the chart below and position

the Belt (59) on the Pulleys (16, 60)

according to the desired drill speed.

4. When the Belt has been correctly positioned, tighten

it by pushing the Motor away from the Headstock until

the belt deflects by approximately 1/2″ at its center

when using reasonable thumb pressure. Lock this

position in with the Motor Tension Knob (10).

Deflection

Distance

Figure G: Belt Deflection

Note: If either belt is too long to be properly

tensioned, it must be replaced.

760 RPM

Spindle Motor

1150 RPM

Spindle Motor

1630 RPM

Spindle Motor

2180 RPM

Spindle Motor

3070 RPM

Spindle Motor

Figure H: Drill Speed Table

The table above shows the belt arrangements for given drill speeds.

A full chart is also located on the inside of the pulley cover.

Light Bulb Installation

1.

To prevent injury, allow the old

Light Bulb (73) to cool completely first.

2. Remove the old Light Bulb (73) from the

Lamp (34) and dispose of it properly.

3. Install a new Light Bulb of the same type and rating.

(E14 base, 120V, 15W)

WARNING! TO PREVENT SERIOUS INJURY

FROM FIRE: Do not install a different style Light Bulb

or a Light Bulb with a higher wattage rating.

Drill Bit Installation

1. Insert the drill bit into the jaws of the Chuck

approximately 1″, ensuring that the jaws

do not touch the flutes of the drill bit.

2. Before tightening the Chuck, ensure that

the drill bit is centered within the jaws.

3. Tighten the Chuck securely with

the included Chuck Key.

SAFETY

OPERA

TION

MAINTENANCE

SETUP